The long-awaited moment of completion of construction has arrived, all that remains is mere trifles: cladding the façade of the building, not forgetting, of course, the basement. This name refers to the part of the foundation that rises above ground level. The base needs to be reliably strengthened and must be in harmony with the overall exterior of the building.

Base cladding options

The construction market offers many ideas for cladding the plinth. The materials used for these purposes come in different configurations; they can only be classified according to the raw materials, so there are the following options:

- stone;

- siding;

- plaster;

- tile.

All methods are good in their own way and usually choose the appropriate one based on cost and overall design project of the building. Some difficulty will arise in choosing the appropriate design of the plinth for wooden house- not all possible finishing materials are suitable here. Let's consider each option in more detail.

Facing the base with stone

A good choice, natural and artificial stone are durable and have high strength characteristics. Installation stone finishing is not always available with your own hands, so the cost of paying employees may increase. In an assortment of various colors and textures, you can choose how to decorate the basement of your home. You can buy some types of artificial stone relatively inexpensively, but here, as always, the price/quality principle works.

Siding installation

Of all the variety, it is better to use special plinth panels. Maintenance of such decor is minimal, the surface can be washed and, if necessary, easily replaced. The disadvantage of using it is the labor-intensive installation process, which includes the installation of a special sheathing and guide. We should not forget about the necessary tolerances for temperature deformations. It is quite problematic to install some types of siding with your own hands. The base of a wooden house is often covered with siding.

The simplest and available method- plastering the surface. At the same time, you can additionally insulate the base using polystyrene foam or polystyrene foam. This decor will decorate any building, except perhaps a wooden one.

The undoubted advantages of plaster include:

- moisture and temperature resistance;

- low cost;

- the ability to do it yourself;

- simple algorithm of work.

The disadvantages will be low strength and service life compared to similar materials, and the need for regular painting and straightening of the surface. It is also impossible to wash away serious stains without leaving a trace, so caring for such surfaces often comes down to regular repairs.

In some cases (large differences in surface level, thick application layer), it is better to use additional reinforcing mesh. This will slightly increase the cost of finishing, but will give the plaster sufficient rigidity and strength. Usage decorative plaster much more effective than conventional solutions, but its cost will also be an order of magnitude higher. In addition, applying decorative plaster with your own hands requires the necessary skills.

Installation of tile materials

As external cladding A wide variety of tile materials are also used.

These include porcelain stoneware or quartz agglomerate - a slab of quartz or granite chips held together by resinous substances. The agglomerate is characterized by high strength and incredible resistance to external influences. This is probably the ideal option for cladding the facade of a building, almost eternal, the only drawback of which is the rather high cost compared to other materials.

Also, when finishing the base, the so-called facade tiles, the main varieties of which are given below and can also be seen in the photo.

Almost all facade tiles can be installed using the “dry” method - on a profile, with additional thermal insulation. If the size and weight of the tiles are quite significant, it is better to use the “wet” method. This method involves the use of an adhesive solution and additional fixation. These technologies can be studied in more detail in photo and video materials.

Master class on plinth cladding

Video tutorial on installation natural stone As a decoration for the basement space, you can see some of the nuances of the work, as well as several new ideas for the design of such work.

Conclusion

Cladding the basement of a building is not a difficult task, especially if you carefully study the construction market offers for such work. The choice of suitable material should take into account not only the final cost of the project, but also the aesthetic orientation of the finish. A base lined with natural or artificial stone will look inappropriate on wooden house. The same applies to the plastered plinth on the facade of the building, lined with porcelain stoneware or facade tiles.

The service life also has important when purchasing suitable material. Excessive savings are not always appropriate here, especially on the quality of facing materials and adhesive composition. It is best to invite specialists for such work, but it is quite possible to install some materials yourself.

The best way to finish the basement of a house with your own hands updated: February 26, 2018 by: zoomfund

The basement is the lower part of the walls of the building, encircling it along its entire perimeter. Its main function is to protect the structure from cold or harsh conditions. environment. It is the finishing of the basement of a private house that not only performs the above functions, but also prevents its destruction and is an excellent design solution for decorating the building.

The main purposes of finishing the foundation:

- the foundation needs constant care and protection from moisture, sunlight and other environmental factors, which increases its service life;

- The surface of the base without finishing is subject to constant contamination, resulting in its destruction. This happens because mud, especially liquid mud, contains many aggressive substances that cause erosion in concrete, contributing to its destruction;

- finishing material protects the foundation from damage by fungus, mold or insects;

- The finishing of the base is carried out in order to insulate it, since by forming a large battery, it sucks out the heat of the building. And even a warm floor will not save you from this process. Insulation of the foundation is also necessary to maintain its strength, since during severe frosts the process of erosion begins;

- home decoration using a variety of finishing materials, which perform the role decorative element V design. An example will be shown in the photo.

Types of finishing materials

Do-it-yourself finishing of the base is done using a variety of materials, reliably protecting and decorating its surface. It is recommended to start the process of cladding the base before finishing the walls, so that when using ebbs they can be hidden under facing material walls

Before deciding on the choice of material, you need to pay attention to the following nuances:

- when finishing the base with thick building material, it will be necessary to additionally install a drip molding on the surface of its protruding part;

- for a significant expansion of the foundation it is possible to use brickwork;

- when using corrugated sheeting or siding, a frame is installed to secure them, into the spaces of which a heat insulator can be inserted, further insulating the foundation;

- The use of frame-cladding technology allows for repairs to be carried out at any time.

For cladding the base, the materials described below are used.

Brick

- slotted;

- ceramic;

- hollow stone;

- hyper-pressed modifications.

Ceramic

Ceramic  Hyper-pressed

Hyper-pressed  Hollow

Hollow  Slotted

Slotted The laying technology is as follows:

- it is necessary to create an additional foundation. To do this, having made a depression 30–40 cm both in length and in depth from the foundation walls, it is filled with crushed stone, compacting it well;

- a layer of waterproofing is laid;

- Brick laying is done in half bricks, in rows of spoons;

- after passing 3 rows of brickwork, holes are cut in the base and reinforcement of 6–10 mm is inserted, which is necessary to connect the surface with the facing material.

- it is possible to lay a thermal insulation layer between the brickwork and the wall, the joining of which can be carried out with wall thermal insulation, if present. In its absence, the insulation is placed on top of the base under the façade cladding material.

Clinker

Clinker has an affordable price and the following advantages:

- has a good operational resource;

- there is no need to create your own foundation;

- Presence of ready-made corner parts;

- due to the light weight of the material, the force load on the frame is minimal;

- decorative coating has artistic value;

- variety of tile types:

- torn stone style;

- imitation brickwork;

- looks like a polished rock.

Fastening clinker tiles can be done in two ways:

- this is done using special glue;

- frame, which allows not only to decorate the foundation, but also to insulate it by inserting a heat insulator into the spaces of the sheathing.

Artificial stone

Artificial stone represents concrete slabs having a decorative outer layer. To improve its characteristics, it is modified with special moisture-resistant additives, and for increased wear resistance, its front side is painted.

This facing material is suitable for any façade covering.

The technology of its fastening, all the nuances:

- cleaning the foundation from dust and all kinds of contaminants. When finishing an old foundation, eliminating its errors;

- surface primer;

- applying the adhesive solution and fastening the slabs.

Natural stone

Natural stone is a heavy material that significantly weighs down the strength frame of the house. The following types of natural stone are used:

- granite;

- dolomite;

- gravel.

Advantages of natural stone:

- high strength;

- waterproof;

- long service life.

The disadvantages of the material are the following:

- impossibility of insulating the base;

- limited maintainability;

- the presence of many mortar joints, the finishing of which requires additional costs.

The fastening technology is as follows:

- before laying the stone, the surface of the base must be cleaned and treated with a primer;

- the stone is fixed to cement mortar;

- After laying the stone, all mortar joints must be treated with a special grout to ensure their waterproofing, since the mortar does not have these properties.

Panels

Plastic panels are very popular in finishing not only the basement, but also the entire house. They have many advantages:

- wide range of colors;

- various textures imitating natural stone, marble, granite and so on;

- affordable price;

- simple installation;

- possibility of insulating the base;

- moisture resistance, sun rays and temperature changes.

The fastening technology is as follows:

- a frame made of metal profiles or wooden slats is installed;

- prepared panels of appropriate sizes are joined and attached to the sheathing using screws;

- facing of corners is carried out using corner, ready-made elements;

- The flashing is installed on the upper part of the foundation finishing.

Plaster

One of available options finishing the foundation is plastering its surface. However, the finishing does not end there; to protect the plastered layer from moisture and other external factors environment, it must be treated with special moisture-protective agents, such as acrylic paint, water-based paint or oil-based compositions. Thanks to them, the decoration of the base is also carried out.

Plastering technology can be:

- the first option is to plaster the base and then paint it;

- the second option is to insulate the base, plastering and applying a layer of paint or decorative plaster.

It is possible to use decorative plastering technology, resulting in a surface that looks like a fur coat. To obtain a colored fur coat, dyes are added to the solution.

Mosaic plaster is also popular. It contains fine crumbs, which, after drying, create the impression of a multi-colored mosaic. It has waterproof properties due to the resin in its composition as a binder.

Tile

Making tiles from a polymer-sand composite is an inexpensive option from the above. Advantages of this material:

- has different formats;

- plastic structure, due to which the tiles do not crack;

- light weight of the material;

- has an attractive texture, imitating natural stone or brickwork;

- has good resistance to moisture, sunlight, and damage.

Disadvantages include the lack of additional elements, which requires adjustment in finishing the corners.

The tiles can be fixed in two ways:

- the first method involves attaching the tiles to a special glue, after first cleaning and priming the surface;

- the second method involves creating a sheathing on which it is attached. This method has the advantage of being able to insulate the façade.

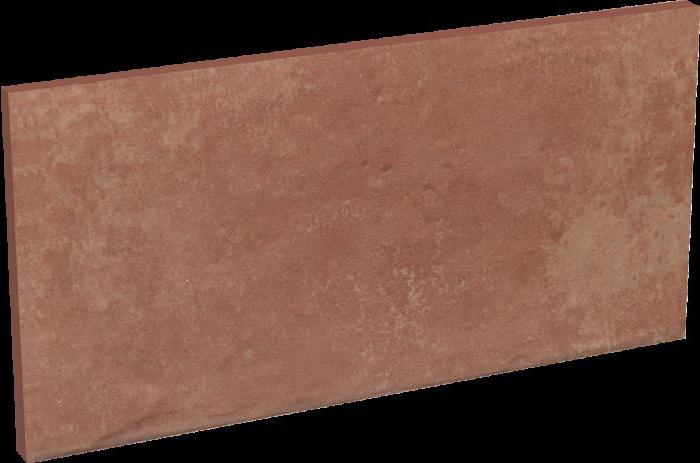

Porcelain tiles

The production of porcelain tiles is carried out from various types clay with the addition of granite chips. Thanks to this, the material has a strong structure and is suitable for finishing not only walls, but also the base. Advantages of the material:

- wide choice of colors and textures;

- when used, there is a slight load on the foundation frame;

- retains its appearance for a long time;

- has good moisture resistance;

- durability;

- does not absorb dirt and dust;

- easy care.

The tiles are laid using a special adhesive. After which the seams must be treated with moisture-resistant compounds.

Decorating the finishing layer of the base surface is carried out in the following ways:

- painting with paints suitable for the facade. The advantages of such decoration are the ability to choose a color, shade or draw a pattern that matches the façade decoration and overall design Houses. This method is also the most affordable of many;

- applying finishing decorative plaster. Thanks to a wide selection color palette she can satisfy any requests of home owners;

- decorating the base surface can be done from a regular plastered surface, giving it relief irregularities. After such a surface has dried, the finish of the base resembles finishing stone. The shape of the irregularities can be made in any way, at the discretion of the owner of the house.

Photo different ways plinth decorations are presented below.

Finishing features

The base is the foundation of any building, so the importance of its finishing speaks for itself. Since the base is constantly exposed to external environmental factors, finishing materials must be durable, resistant to moisture, cold and sunlight.

The finishing material should not only protect the base from adverse factors, but also give an aesthetic appearance to the building. The finishing of the base is done before finishing the walls. There are two types of plinth finishes, raised and recessed, each of which has its own advantages. To improve the adhesion of finishing materials and the foundation, a primer is used.

To summarize, we can say that the finishing of the plinth is of great importance, it acts not only as a decorative element when decorating a private house, but also acts as its protector, since the plinth is one of the main parts of the building - it is its foundation. For its finishing, various building materials are used with different characteristics and properties, the choice of which is made based on the personal preferences of the owner and his financial capabilities.

When constructing any house, it is equipped reliable foundation, which can be represented by one or another construction. The importance of this element cannot be overestimated, because it is it that takes on the weight loads and distributes them. The foundation usually protrudes above the ground surface, forming a plinth.

After completion construction work The owners are faced with the question of how to decorate the basement of the house from the outside. There are a lot of options for solving this problem. After studying them, you can understand which finish to prefer. Some private property owners are wondering why they should use basement finishing at all.

These works are carried out in order to make your home as attractive as possible. However, the cladding of the base performs not only this role; it also protects the materials at the base of the foundation from destruction. After all, they are influenced by external unfavorable factors. Among them are humidity, wind and temperature changes. In addition, the walls at the plinth level are subject to contamination to the maximum extent.

If you want to protect the base from the emergence and development of biological life, then it is worth installing cladding on it, then the materials will not become covered with colonies of fungus and mold. If possible, you can also provide insulation for this part of the house. The base array is a capacious cold accumulator, where bridges and entire pipelines are formed for the penetration of low temperatures into the premises. Part of the energy resources spent will be wasted if thermal insulation is not implemented.

The material at the base of the foundation will freeze under the influence of low temperatures, which activates erosion processes and reduces strength. IN in this case we can conclude that the base needs finishing during the operation of the building not only for decorative reasons.

Base finishing options: plastering and painting

If you are also wondering how to decorate the outside, then you can use one of the most simple ways- plaster. This finish can create a good protective barrier with high vapor permeability. The main advantage of this method is its low cost, because the material is one of those available on the market.

You can perform such work yourself or use the services of a plasterer. But if you want to create not only an effective barrier on the surface of the base, but also make it attractive, then the surface can be painted with a resistant facade paint. It is offered for sale in a wide range, and the consumer has the opportunity to choose the appropriate option.

As a finishing layer, you can use decorative plaster, which is offered by manufacturers in a wide palette of colors. You can give the plinth a variety of textures, one of which will certainly satisfy the homeowner’s needs. If you use your imagination, you can make a plastered surface very original. To do this, the base is given the appearance of natural materials, for example, stone.

Directly on the surface of the base you can form something similar to natural stone. For modeling in this case you do not need to have special skills. The main thing is to prepare a high-quality dense solution. After hardening, all that remains is to decorate with dyes. The disadvantages of such technologies include the fragility of the coating. The condition of the layer will have to be monitored by promptly repairing or updating damaged areas that have become covered with cracks.

Variety of materials: natural stone

When deciding how to decorate the outside of the house, you can become more familiar with natural stone. This decision can be called elitist. A building with such a design for the base will look advantageous, and the natural material will show all its performance characteristics and will be ready to serve for quite a long time.

For cladding, special stone slabs called slabs are used. Their thickness usually varies from 20 to 30 mm, they can have correct form or uneven edges, which allows for greater decorativeness.

The surface can be selected to suit your taste; it can be mirror-like, polished to a shine, or have rough chips. Despite all the practicality and beauty of this type of finish, it has many disadvantages, including:

- impressive weight;

- increased complexity of installation;

- high cost.

As for weight, it will put additional load on the base of the building, this is especially true in cases where the base has a large surface area. If you plan to finish this part of the building with natural stone, then you need to calculate everything at the design stage, so as not to have to strengthen the foundation later. The large mass of products makes installation more difficult. Even the use of the highest quality glue sometimes does not cope with the situation, so there is a need for additional shaping and creation of stops.

If you still don’t know how to decorate the outside of the house’s basement, then you should take a closer look at several solutions at once. Among others, natural stone should be highlighted. It is environmentally friendly, looks very attractive, but has one significant drawback, which is expressed in high cost. This also applies to price installation work, which is important for those home owners who do not plan to do the work themselves.

Even the most budget types natural stone have a fairly high cost, which varies from 1200 to 1500 rubles. for square meter. In this case we are talking about limestone and shell rock. But among the more expensive ones you can highlight marble and granite, which have a chipped or polished surface. If you want to make your home exclusive, then you can use materials such as labradorite and gabbro to decorate its basement, but you should be prepared for the fact that the cost of them is truly exorbitant.

Use of artificial stone

A private home can also be decorated with artificial stone. If you love the look of natural material, but are on a budget, then this is the solution for you. It has many positive features. Among others, it is worth highlighting the affordable cost, as well as the low weight. But in the end it is possible to achieve an almost complete illusion of natural stone.

This material is made on the basis of cement-containing mixtures, to which light fractions, micro-reinforcing substances and polymer plasticizers are added. Among the components of stone for finishing the base of a house one can highlight expanded clay crushed stone. The slabs are made using vibration casting technology in silicone molds and accurately follow the curves of the natural texture.

Production may involve the use of the hyper-pressing method. If you are thinking about the question of whether you want to finish the basement of a private house with artificial stone, you should understand its varieties. Among others, it is worth highlighting products that are standardized or one-piece. No less popular are sets equipped by one area. This type of finish is installed in the usual way, which involves laying the products on tile adhesive.

To facilitate the installation process, you can purchase ready-made panels. At the production stage, mounting brackets are installed into the concrete structure, which have a precise geometric location. These parts allow panels to be installed to the surface using mechanical fasteners rather than mortar. In this case, there is an undeniable advantage, which is expressed in the simplicity of the work.

The technology involves the use of guides. If desired, such panels can also be installed on a mortar; the brackets are bent inward, which makes the coating more reliable. On sale you can also find tiles made of artificial stone, which are installed with polyurethane glue. The base must be rigid.

Additionally, you can use a layer of insulation. The latter is fiber cement, glass magnesite or OSB. In this case, the base will acquire additional thermal insulation qualities.

The joints between the panels will be completely hidden, which was thought out by the manufacturer, who produces products with a locking part. As a result, it is possible to achieve the effect of natural stonework. The outer surface can have a certain texture, which is chosen by the consumer; among other solutions, crushed stone, rock, slate and tuff should be highlighted. Mosaic solutions that involve the inclusion of artificial mini-slabs with different shades and textures are also quite popular today.

Using a brick finish

If you are faced with the question of how to decorate the basement of the house from the outside, photos of the available options will be the best helpers. Some, by the way, are presented in the article. Among other modern solutions, brickwork should be highlighted. It gives the building respectability, and as a result, the facade is in harmony with any type of decoration of the rest of the wall area.

When choosing materials for finishing the basement of a house, you can use natural brick cladding. This approach has important advantage, which allows you to create a ventilated gap between the cladding and the base. You can fill the space with thermal insulation. The brick itself will serve as an additional barrier to the cold. But the masonry will need strip foundation, therefore, this issue must be considered at the construction planning stage.

Some experts recommend doing things differently - creating your own support for the masonry, which will be combined with concrete blind area around the base. The finishing of the basement of a private house, the photo of which is presented in the article, can also be carried out even if it has low water absorption. Such products are just suitable for the base; they can have the most different sizes, But Russian manufacturer offers for sale standard parameters, they are equal to 250 x 120 x 60 mm.

For reference

Most economical option is sand-lime brick. But especially popular for such species finishing works he doesn't use it. The hollow internal structure of ceramic bricks, including clinker bricks, allows the weight of the cladding to be reduced and provides a thermal insulation effect. But it is not always possible to do real brickwork. If you still want to make a base in the form of imitation brickwork, you can use clinker tiles.

Finishing the basement of the house, photos of which are presented in the article, will have high performance characteristics that are not inferior to brick. If the tiles are laid according to technology, it will allow for reliable visibility of the brickwork.

Using panels

Panels for finishing the basement of a house are also quite common. They are elongated flat products with locking connections and mounting holes for mounting on a base. This cladding is distinguished by its large thickness, increased strength and small width. As for thickness, plinth panels it reaches 3 mm. Such products are usually wider and shorter, which is convenient when the height of the area to be finished is small. In this situation, one row may be enough.

The mass of the coating is small and amounts to approximately 4 kg per square meter, so there is practically no additional load on the foundation. You can install this exterior finishing of the basement in a private house yourself; it is also good because it can have a shade that is similar to the rest of the facade cladding. As a result, it is possible to obtain a durable barrier that does not need to be treated with protective compounds, which distinguishes it favorably from wood and natural stone.

Features of panels

This finish is inexpensive, it is resistant to temperatures and water, as well as ultraviolet rays. The material is not subject to rotting, fungal growth and corrosion. It is characterized by plasticity mechanical strength. After impact deformation, the panel restores its original shape, which distinguishes it favorably from metal panels.

Using siding

This architectural and design solution allows you to decorate and protect the base with minimal costs. Siding is performed in imitation of various natural materials, including:

- stone;

- brick;

- wood.

However, this list is not complete. Panels can have a variety of textures and shades. If you are thinking about how to inexpensively decorate the basement of a house outside, you can take a closer look at siding, which is made from polypropylene. It contains special additives that make the material durable and elastic.

More about siding

The trim is installed on the sheathing using self-tapping screws or galvanized nails. The convenience of using such cladding lies in the absence of the need to pre-level the surface. Easy joining of panels is ensured by the presence of a groove system. If you are faced with the question of how to decorate the outside of the house with stone, then you can use siding, which gives the building a respectable and solid look. With this solution, you can make the finish contrast using artificial and natural materials. Sometimes panels are used that have a smooth or glossy surface.

In conclusion

The most vulnerable part of any building is the base, because it is located closest to the soil, which negatively affects the materials. It contains moisture, contact with which can cause destructive consequences. For this reason, many owners of private houses are thinking about the question of how to decorate the base of the house from the outside inexpensively (photos of such solutions are presented in the article, as well as a description of these materials). The most suitable options in this regard include siding, natural and artificial stone, as well as clinker tiles and natural brick.

You can decorate the base of the house with various materials that can reliably protect the upper part of the foundation from getting wet, solar ultraviolet radiation, and mechanical damage. Typically, brick, clinker, stone masonry or siding are used - polymer or composite panels that qualitatively imitate masonry.

There are all types of cladding available on construction markets. Before deciding which material would be better suited For architectural style cottage, the following factors must be taken into account:

- the protruding base will have to be additionally protected with ebb tides;

- flexible tiles that can be used to cover a concrete surface have a minimum layer thickness;

- Brickwork expands the plinth structure to the maximum;

- inside the frames on which panels, siding or corrugated sheeting are attached, insulation can be placed to eliminate heat loss through the ceilings and floors of the lower floor;

- By default, frame systems are more maintainable and can be updated at any time during operation.

Advice! It is better to decorate the protruding plinth before facing the facades, so that, if necessary, hide the upper fastening flange of the ebb under the finishing material of the wall.

Brickwork

To cover the base with brick, it is necessary to make a separate base for the masonry. On heaving soils, this requires replacing 40 cm of soil with crushed stone and/or sand compacted in layers.

Unlike a concrete foundation, this facing material has half the service life when in contact with the ground. On top of the underlying layer, roll waterproofing in 2 - 3 layers is required. To completely eliminate subsidence of the brickwork, a rigid bond with a plinth is used:

- after laying 2–3 rows, blind holes are drilled in the supporting structure to a depth of 4–6 cm;

- 6-10 mm reinforcement is inserted into them, connecting the main wall with the cladding;

It is recommended to use ceramic brick, slotted, hollow stone or hyper-pressed modifications. The masonry is carried out exclusively in half-brick rows. To eliminate the cold bridge, which is essentially the design of the plinth, between the facing brick and load-bearing structure Basalt wool or extruded polystyrene foam can be used.

Important! The insulation must be combined with the thermal insulation of the facade or placed along the top of the plinth inside under the layer of wall cladding if there is no thermal insulation.

Clinker

You can finish the ground part of the foundation of the house with clinker tiles. The budget will be approximately equal to brick cladding. However, this material has some advantages:

- the maximum possible service life of all known claddings;

- availability of ready-made corner (external/internal) elements;

- fastening to walls, no need for your own foundation;

- slight loading of the load-bearing frame due to the low weight of the clinker;

- high artistic value of decorative coating.

There are different types clinker tiles that imitate masonry, torn, rock, polished stone. Therefore, you can choose a design option for the base in full accordance with the architectural style of a private cottage.

Clinker tiles are attached glue solution, panels made of this material are attached to the frame. The first option does not allow you to insulate the above-ground part of the foundation, the second allows you to install polystyrene foam inside the sheathing.

Advice! There are clinker tiles for steps, which allows you to achieve maximum aesthetics in the perception of facades when finishing the plinth with the same material.

Polymer sand tiles

An inexpensive option for finishing the basement of a house is a polymer-sand composite, from which tiles of different formats are made. This material is very light, practically does not load the foundation structure, and is attached either to the frame sheathing or to tile adhesive.

The texture usually imitates natural stone or brickwork. The material is moisture-resistant, with a minimal coefficient of expansion, resistant to solar ultraviolet radiation, aggressive environments and mechanical damage. The tiles are cut with a hand saw in any direction; you can choose any format to reduce cutting waste.

Important! Additional elements for this cladding do not exist, so precise adjustment in corners and joints is required.

Natural stone

If there is cheap natural stone in the region, you can finish the basement of the house with this material. This option is more suitable for seasonal buildings in which external insulation of the underground and above-ground parts of the foundation is not required. Heavy material is placed on mortar or tile adhesive, significantly loading the strength frame of the cottage, and does not adhere to the insulation.

Granite, gravel, dolomite stone has high strength and moisture resistance. However, when facing, many mortar joints are obtained that do not initially possess the indicated characteristics. Therefore, finishing costs increase for the purchase of grouts, which provide waterproofing of joints.

Important! The stone cannot be fixed to the frames, so the maintainability of the cladding is zero.

Artificial stone

Of all the modifications of artificial stone, concrete slabs with a decorative outer layer are usually used to finish the base of a house. To improve its characteristics, the material is modified with moisture-resistant additives and painted according to the mass to increase the wear resistance of the front surface.

The fastening of artificial stone is standard - an adhesive layer after treating the foundation with a primer. This cladding can be used with any façade covering. Integration into the exterior and architectural style is high by default.

Tiles, porcelain stoneware

To finish the basement of a house with tiles or porcelain stoneware, you will first have to level the surfaces. Layer thickness adhesive composition should not exceed 1 cm, modifications can only be used for external use.

Porcelain tiles are much stronger, tiles wider range, richer choice of textures, colors and formats. Therefore, when using tiles, cutting costs can be reduced. The material slightly loads the foundation; the seams are rubbed with special moisture-resistant compounds.

Important! Tiles are not a complete waterproofing material. Therefore, the surface of the base before facing can and should be treated with a primer and coated bitumen mastic. The tiles do not adhere to glass hydroisolate.

Plaster

A budget option for finishing the basement of a house is traditionally leveling the surfaces with plaster and putty solutions. However, these materials require protection from moisture and additional decoration. Therefore, they are painted with water-based, dispersed, acrylic, acrylate and oil compositions.

The same materials are used in wet facades, since they adhere quite firmly to polystyrene foam or basalt wool when used reinforcing mesh. Therefore, the base of a building for seasonal use can simply be plastered and painted, the base of a house permanent residence it is better to insulate and plaster and cover with decorative plaster.

Basement siding

If you're on a budget, vinyl basement siding may be a better choice for your building. Despite the name, entire facades are often finished with this material on the outside. For example, a budget “frame” can be completely covered with basement siding, giving the home the architecture of a brick cottage.

Photo of a panel of vinyl basement siding imitating brick.

Unlike standard linear panels, basement siding Available in the form of modules with dimensions of about 1.2 x 0.5 m, 18 - 30 mm thickness. The texture usually imitates stone or masonry; the panels have locks to connect them together. Insulation can be placed inside the frame sheathing, reducing the heat loss of the building.

Important! Basement siding has the widest range of additions. In addition to ebbs and corners, manufacturers produce starting and finishing strips and clamps for concealed fastening of panels.

Profiled sheet

Lining the ground part of the foundation with corrugated sheeting is budget option. In this case, the facades are of low artistic value, so it is better to use this cladding for outbuildings. Installation is carried out on a frame made of timber or galvanized profile, fixed to the base from the outside.

Sheets can be fixed to purlins with rivets or self-tapping screws. For profiled sheets, there are additional elements that allow you to qualitatively decorate external and internal corners, install ebb tides above the base.

Important! When choosing corrugated sheeting, there is virtually no cutting waste, since you can order sheets of the required height that are mounted without adjustment.

Flexible tiles

This method of cladding the ground part of the foundation is, in principle, not the intended use of roof cladding. Flexible tiles are very thin and cannot hide even minor flatness defects, so they require a perfectly flat base.

This decoration technology is more suitable for installing columnar or pile-grillage foundations. By carrier vertical elements the lathing is stuffed or purlins are attached, asbestos cement sheets are hung on them, their surface can be covered with flexible bitumen shingles, additionally secured with self-tapping screws. Typically, the types of tiles that are most similar to stone are chosen.

Use for finishing the basement of a house composite materials made of fiber cement allows you to provide a 20-30 year resource. The panel is created from a mixture of cement and wood fibers hot pressing, the outer surface is laminated or covered with a protective layer. They are made to imitate various materials - wood, brick, stone.

In addition to weather resistance and a self-contained front design, fiber cement panels have self-cleaning properties. Dust and dirt are washed away by rain or water from a hose. The panel locks are supplemented with sealing elements that ensure high tightness of the facing layer.

Photo of a plinth made of fiber cement panels

Thus, the base can be decorated in many ways, depending on the available construction budget, the architectural style of the building and the preferences of the owner. It is necessary to focus on the service life of the coatings, the weight of the cladding, the thickness and price of the materials.

Advice! If you need contractors, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

After the walls of the house are erected, it is time to finish it, including finishing the foundation, or basement. In addition to the most obvious function - decorative - finishing the foundation of a wooden house or brick building performs several more important tasks.

- It protects the wall material from precipitation and wind.

- The finishing creates an additional thermal insulation layer, preventing concrete foundation cool down in winter and take heat away from the house.

- The finish protects the foundation from dirt, and many materials are much easier to clean than bare concrete.

In the article you will find a description of finishing materials for the plinth, tips on their use and photos of houses.

Finishing materials

Plaster

The easiest way is lighthouse plaster. It is called that because to ensure its even application, beacon marks are installed on the wall. Most often, lighthouse plaster is not used as final finishing, but to prepare the wall before applying decorative plaster or finishing with other materials.

Decorative plaster does not necessarily have to result in a smooth surface. Using stencils, you can apply a relief design on it, and with certain skills you can even make an imitation of stone or brick.

Siding

Finishing the foundation with siding is a modern solution. This material weighs little and is sold in the most different options colors and textures and three standard sizes: 120*80 cm, 60*18 cm and 40*18 cm, easy to install. To finish the basement, they use not ordinary, but special basement siding - it is more durable due to a different composition. High-quality siding for exterior finishing withstands high and low temperatures (from -50 to +60), does not deform, does not lose color in the sun and retains its beautiful appearance and strength for a long time.

Before installing the siding, a special starting profile is installed in the lower part of the wall. The siding is attached to special horizontal or vertical guides that are mounted on the wall. The panels are fastened together with a tongue-and-groove joint. Additional elements are installed in the corners. The finished base is covered from above with a special plinth. Siding does not require additional processing.

Profiled sheets and corrugated sheets

Profiled sheets and corrugated sheets are profiled metal sheets. These varieties differ in that the profile on the profiled sheet is more rigid. Their main purpose is to serve roofing material, but due to their strength, relatively low price and durability, they are also used for other purposes, for example, finishing the foundation of a house with corrugated sheets and building fences. The corrugated sheet can be either galvanized or have a polymer coating. To finish the foundation with a profiled sheet with your own hands, use a wall profiled sheet with a thickness of 0.6 mm. To cover the foundation you need corners, a profile for guides, self-tapping screws, dowel anchors, and ventilation grilles. First, a sheathing made of metal profiles or wooden blocks is attached to the foundation. Then the corrugated sheeting is cut and attached to it with self-tapping screws with a waterproof gasket.

Resin based tiles

This material can imitate any natural cladding: wood, stone, brick.

The tiles are glued to the leveled and primed surface of the foundation. To lay the tiles evenly, markings are first applied to the wall. You can glue tiles not only directly to concrete, but also to thermal insulation. Start laying the tiles from the corner, and you need to make 4 rows at once. The glue protruding from the seams seals them. After completing the work, the foundation should be protected from precipitation for 2-3 days. During this time the glue will dry. The finished foundation does not require any additional processing.

Clinker tiles

This is an option facing bricks, made from special types clay. It has an interesting appearance due to the unique pattern of layers of clay mixed during the production process, it looks like brickwork and gives the house a touch of antiquity.

Facing brick

This is a natural ceramic brick that perfectly imitates brickwork, additionally insulates and protects the facade. The downside is that the material is quite heavy. If you want to finish the foundation with brick, you need to plan this in advance, even at the stage of developing a house project, so that the wall can definitely withstand the weight of the cladding.

Artificial stone

Finishing the foundation of a house with stone is done using artificial stone made from concrete. It can imitate river, sea, hewn or natural stone, brickwork. Artificial stone for finishing the foundation of a house costs significantly less than natural stone, is durable, and resistant to temperature changes. It is easy to install: the tiles are glued to a leveled surface with special glue. After the glue has dried, the seams are filled with a water-repellent agent. The photo shows the facades of houses with stone finishing.

Cement particle boards and flat slate

To obtain a flat surface when finishing the foundation with your own hands, they often use flat slate or cement bonded particle board(DSP). Slate contains asbestos fiber, Portland cement, and water. IN composition of the DSP- wood shavings, Portland cement, chemical mineralizer additive (aluminum sulfate, sodium and potassium silicates), water. Slate can be pressed or unpressed; unpressed slate is inferior in strength and durability. DSP is less durable than slate, but lighter, and due to the chemical mineralizer in its composition, the shavings in its composition are protected from moisture. A layer of decorative plaster or paint is usually applied to the DSP or slate.

Most often, to finish the foundation, they use not standard gray DSP, but embossed, painted or covered with stone chips. DSP-based facade slabs have many advantages:

withstands more than 100 freeze-thaw cycles,

- lungs,

- environmentally friendly,

- provide additional sound insulation,

- the composition of the boards prevents the appearance of mold on them.

- they are easy to cut, mill, drill at home,

- easy to install on the façade using a dry method.

To mount the DSP on the foundation, you need to prepare the sheathing. It is attached to the prepared, leveled surface of the foundation. The pitch of the lathing is no more than 60 cm. The lathing can be made of wood or a metal profile; in this case, the wood must be dried and treated with an antiseptic.

Attention! DSP is a fragile material and must be protected from impacts.

Holes are drilled in the CBPB sheet; steel drills are used for this; tungsten carbide drills are also acceptable. Drills for hard materials should be used. For fastening, use special galvanized nails, screws or self-tapping screws with a countersunk head. The distance between them should be about 20 cm. It is not recommended to use fasteners designed for drywall.

Finishing the foundation in a wooden house

Finishing the foundation of a wooden house creates an additional heat and moisture insulating layer and increases the service life of the foundation. Typically, natural materials are used to decorate a wooden house:

- natural stone,

- brick,

- clinker tiles,

- porcelain stoneware

Foundations wooden houses They are also finished with vinyl panels (siding).

The peculiarity of finishing the base in a wooden house is that in this case it is especially important proper waterproofing. A waterproofing layer is made on the foundation at a height of 20-30 cm from the ground. Thermal insulation is also installed. After this, you can line the foundation. Some experts recommend doing this not after the walls are completed, but as soon as the foundation is ready, so as not to damage it during the construction of the rest of the house.

Rough base protection

Before finishing the foundation of a house with your own hands, first make its rough protection. It is carried out in several stages.

- Making blind areas. The blind area is an inclined strip filled with concrete. It is made 25 cm wider than the roof extension. Before this, part of the soil is removed and a drainage cushion of crushed stone and sand is laid. Then a layer of concrete about 20 cm is poured on top. The blind area should have a slight slope from the foundation. They do along their edge expansion joints from damper tape.

- Plastering. For more comfortable work A metal mesh is attached to the foundation.

- Waterproofing. It can be done as follows: coat the foundation with hot bitumen; cover with several layers of roofing material; coat with a penetrating waterproofing compound.

After these activities, you can begin decorative cladding.

Now you can find materials for self-cladding the foundation to suit every taste and budget. But it is important not so much to choose one of many materials as to properly organize waterproofing and thermal insulation and carry out high-quality finishing work. Then the beautiful base of the building will not lose its appearance for a long time and will serve as protection for the house from external influences.