Among modern thermal insulation materials The most popular type is polystyrene foam or, scientifically speaking, expanded polystyrene foam. It is produced in the form white slabs with a wide range overall dimensions. The material is very light: the weight of one cubic meter, depending on the brand, ranges from 8 to 35 kg.

Properties of foam plastic as insulation

Currently available for sale different kinds insulation materials. or another insulation?

Currently available for sale different kinds insulation materials. or another insulation?

The wide demand for polystyrene foam is primarily due to low cost. However, this is not its only advantage. The light weight of the slabs, as well as the fact that they are rigid, unlike, for example, mineral wool, ensures simplicity and high speed of installation. Even one person can easily cope with this task without the involvement of any special equipment. technical devices, not to mention heavy equipment.

At the same time, polystyrene foam is a fairly effective heat insulator: its thermal conductivity coefficient is only 0.04 W/m*C(value for brands with medium density).

The technical characteristics of polystyrene foam as insulation make this material fragile. Depending on the circumstances, this quality can turn into either an advantage or a disadvantage. For example, Due to its low strength, foam plastic is easy to process; it can be cut as desired directly during installation. On the other hand, when insulating a building from the outside, the material must be protected with a metal mesh and a layer of plaster. For the same reason, care should be taken during installation, since a foam board of any thickness is very easy to break.

Being completely synthetic in nature, polystyrene foam is not subject to rotting, however, for some reason it is very popular with rodents. Having found even slight access to the heat insulator, they quickly gnaw entire holes in it. But, although interest from rodents is highly undesirable, it the best way indicates the environmental friendliness of the material.

Another enemy of polystyrene foam is ultraviolet radiation. In the absence of protection from solar radiation, the material quickly begins to crumble, becoming unusable. Contact with some paints and varnishes also contributes to the destruction of the foam structure.

The use of foam plastic for thermal insulation

Wall insulation

Polystyrene foam is widely used as insulation for external walls, and even owners of city apartments have begun to do this in the face of significant increases in energy prices.

Polystyrene foam is widely used as insulation for external walls, and even owners of city apartments have begun to do this in the face of significant increases in energy prices.

The polystyrene foam is screwed to the facade of the building with dowels, then plastered, after laying a metal mesh on top of it.

Another common option is:

- Polystyrene foam is laid in the spaces between the sheathing bars, the cross-section of which corresponds to the thickness of the slabs

- Siding panels are attached to the sheathing with seams sealed polyurethane foam

A mandatory requirement for rooms insulated externally with foam plastic is high-quality ventilation. This is due to the low vapor permeability of the insulation. It is not recommended to use this material for insulating rooms with high humidity, for example, saunas.

Insulation of basements and plinths

When insulating basements, foundations and plinths with foam plastic, the low strength of this heat insulator should be taken into account. IN winter period he will experience significant loads from the freezing soil, which, if unprotected, will lead to its deformation or destruction. For this reason, a brick or concrete lining is constructed outside the thermal insulation layer of foam plastic.

When insulating basements, foundations and plinths with foam plastic, the low strength of this heat insulator should be taken into account. IN winter period he will experience significant loads from the freezing soil, which, if unprotected, will lead to its deformation or destruction. For this reason, a brick or concrete lining is constructed outside the thermal insulation layer of foam plastic.

Floor insulation

The environmental friendliness of polystyrene foam has led to its widespread use inside buildings. For example, it is often used as a thermal insulator in floor construction. Polystyrene foam is laid on top of the waterproofing layer, filling the seams with polyurethane foam or silicone sealant. Then a screed and a finished floor covering are laid on top of the slabs.

The environmental friendliness of polystyrene foam has led to its widespread use inside buildings. For example, it is often used as a thermal insulator in floor construction. Polystyrene foam is laid on top of the waterproofing layer, filling the seams with polyurethane foam or silicone sealant. Then a screed and a finished floor covering are laid on top of the slabs.

Methods of roof insulation

Thermal insulation of roofs using foam plastic is carried out using one of two technologies:

Thermal insulation of roofs using foam plastic is carried out using one of two technologies:

- Installation of a non-ventilated (warm) roof. With this method, the roof is covered with 70 mm thick foam plastic slabs, which are then filled with bitumen

- Installation of a ventilated (cold) roof. In this case, the foam is attached from the inside roofing so that there is a ventilated gap through which water vapor will be removed

Is foam plastic harmful as insulation?

A significant disadvantage of polystyrene foam is the high danger it poses in the event of a fire. Manufacturers and marketers position this material as non-flammable and point to its ability to self-extinguish, which is especially evident in the presence of a fire retardant additive. However, a material does not have to ignite to be dangerous in a fire.

A significant disadvantage of polystyrene foam is the high danger it poses in the event of a fire. Manufacturers and marketers position this material as non-flammable and point to its ability to self-extinguish, which is especially evident in the presence of a fire retardant additive. However, a material does not have to ignite to be dangerous in a fire.

As experience and numerous tests have shown, exposure to flame and high temperatures provokes thermal decomposition processes in foam plastic, as a result of which the air, even at a considerable distance from the fire site, is filled with a large amount of smoke, corresponding in toxicity to substances of the highest hazard class.

The issue of polystyrene foam durability is also controversial. According to the manufacturers, the service life of this material is at least 20 years, however, there is no officially approved test method that allows this statement to be confirmed or refuted.

There are a large number of insulation materials for the home. If foam is not your thing, then you may want to consider other options. For example, which can perfectly protect a house from heat loss. The structure of the material allows the walls to “breathe”, therefore, there will be no problems with rotting and fungus formation.

Rockwool insulation is inherently mineral wool. If you only need to insulate the ceiling, we recommend that you familiarize yourself with the process of insulating the ceiling with mineral wool. You can install this material yourself.

Price

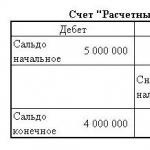

Let's give estimated price on polystyrene foam as insulation of various brands:

Let's give estimated price on polystyrene foam as insulation of various brands:

- PSB-S-15O (density - about 9 kg/cubic m): 1050 rub.

- PSB-S-25 (about 15 kg/cubic m): 1800 rub.

- PSB-S-25T (about 20 kg/cubic m): 2350 rub.

- PSB-S-35 Light (density - from 21 to 23 kg/cubic m): 2550 rub.

- PSB-S-35T (density - from 26 to 28 kg/cubic m): 3050 rub.

The problem of insulating a private house or apartment has always had to be solved, while effective ways arose only after the advent of such building materials as polystyrene foam. Insulating the ceiling, floor and walls with its help allows you to retain heat in your home and at the same time save money.

Polystyrene foam

There is pressed and non-pressed foam; it is not too difficult to distinguish them, even if you are not a professional. If you have ever looked at the structure of a material, you have most likely noticed that it consists of small balls that are interconnected, like a honeycomb in a beehive.

Pressless foam can be seen in boxes with household appliances, since it is actively used for packaging.

By thermal insulation properties And appearance the pressed one is practically no different from the second one, its granules adhere to each other somewhat more firmly, due to which it does not crumble. At the same time, pressed foam is more difficult to produce, which means it is more expensive, which is why it is less widespread.

Technical characteristics of polystyrene foam

This breathable material has low specific gravity, does not accumulate moisture, and is not subject to rotting. His main drawback- this is flammability, although by applying plaster the home can be protected from fire.

Polystyrene foam characteristics:

- biological and chemical resistance to sea water, alkali, salt, soap, cement, bitumen, lime, gypsum;

- low thermal conductivity;

- resistance to temperature changes, due to which the material can be used in different climatic conditions;

- it is not a favorable environment for the development of fungi, mold and microorganisms;

- high vapor permeability - thanks to it, the moisture that accumulates in the walls evaporates;

- excellent soundproofing properties.

Basic properties of polystyrene foam as insulation

Expanded polystyrene is popularly called “foam plastic”. This word comes from the name of a Finnish company that supplied expanded polystyrene to the USSR. The name of the company was transformed over time into the name of this material.

At the moment, polystyrene foam is produced abroad and in Russia various companies. The equipment for its production is cheap, and does not require skilled labor for maintenance and operation.

Now let's look at the properties of polystyrene foam:

Now let's move on to the use of polystyrene foam in low-rise private construction.

Foam insulation: simple and easy

It is done very simply. The polystyrene foam is attached to the wall of the building using special screws. Initially, you can level the wall using putty, attach the slab, then apply a layer of putty again and paint it. This way you get a completely flat wall.

Insulation of buildings from outside

Polystyrene foam as wall insulation is most often used outside. This method makes it possible to move the freezing point to the outer part of the wall, while preventing the cold from penetrating inside.

For this purpose, sheets with a thickness of 100 millimeters are used. They are attached using dowels and special glue. Performing these works at height is only possible using special equipment.

Internal insulation of the room

This method is less common than the previous one, although it is also effective. It is very convenient that it can be implemented regardless of the time of year and weather. But before insulating the walls inside, they are required Preliminary processing special anti-mold compounds.

It must be taken into account that polystyrene foam as insulation usable area reduces the space. This is explained by the fact that it takes up quite a lot of space, especially considering that drywall is attached to the top.

Insulation of building walls

This method is applicable in the construction of 1- and 2-story houses. A wall 250 mm thick is erected, then foam plastic sheets are laid, which are protected plastic film, then the inner wall. This method has the advantage that polystyrene foam as wall insulation is completely protected from open fire and mechanical damage.

Insulation of floors

If we consider foam plastic as a floor insulation (reviews about this use can be seen mostly positive), it is important to take into account that its sheets are laid in a cement-sand liquid mortar during the screed. Air bubbles are expelled using vibration. A 50 mm screed is also made on top of the material.

These measures are especially necessary for residential buildings with damp basements. But in middle-floor apartments, foam plastic as floor insulation will also provide good sound insulation. In addition, this procedure is performed when laying a water-heated floor.

Insulation of ceilings

Such insulation is performed in the same way as with walls. The difference lies in the thickness of the sheets used: it should be no more than 50 mm. In a typical residential building, most apartments have low ceiling heights. Of course, if possible, you can increase the thickness of the foam.

This measure allows you to insulate the apartment, while reducing the noise level and making the home more comfortable.

Basement insulation with foam plastic

It will not be possible to use polystyrene foam in this case due to its hygroscopicity. At the same time, its thermal conductivity increases sharply, and its thermal insulation greatly decreases.

When polystyrene foam gets wet in the autumn and spring, the water in it turns into ice when it freezes, after which it breaks the material. After the first frost, wet polystyrene foam turns into dust, turning into separate balls that are unable to retain heat.

Base insulation with polystyrene foam

But for this it is quite possible to use this material. In this case, foam plastic as insulation is covered with a layer of plaster on top. The foam is attached to the base using plastic “fungi”, to which a fine metal mesh is then attached. Then plaster is applied to it and a decorative layer is applied on top - clinker brick, wild stone, facade tiles.

In this case, you can also use a metal profile for plaster to attach the foam. In this case, it is advisable to abandon the use of a system of wooden blocks. Practice shows that concrete base plinth wooden blocks they begin to rot from below, moisture also gains access to the insulation.

Foam plastic for insulation of a wet facade system

On the facade of the house, the place of foam plastic is located under a layer of continuous decorative non-combustible coatings and plaster. When there is no access to oxygen and open fire, there is no direct impact moisture, this material exhibits its best properties. Don’t forget about the reasonable cost, low thermal conductivity, and light weight.

Roof insulation

Here you need to understand where and what width of material to use. The “non-ventilated roof” is covered with 70 mm thick foam plastic, then a bitumen waterproof layer is laid on its surface. “Ventilated roof” involves installing slabs on the back side of the roof, while the ventilated cavity remains, preventing condensation.

Attic spaces can be great living rooms. At the same time, thermal insulation gable roof brings great benefits at low cost. To do this, you need to install foam plastic in the cracks between the rafters.

Thermal insulation of pipelines

Until recently, thermal insulation engineering communications was not given much importance, and because of them the share of heat loss is about 30%. For pipelines of ventilation ducts, cold water supply, buried cables and telephone lines, foam plastic is now increasingly being used as insulation. This material also used to protect sewer and water pipes from freezing. The undoubted advantage of using polystyrene foam for these purposes is the ability to give this material various shapes.

Where is it prohibited to use polystyrene foam as insulation?

- Expanded polystyrene cannot be used when insulating a bathhouse, since high humidity and heating produces the emission of styrene.

- There is no need to insulate window slopes from the inside - for this it is advisable to use polyurethane foam. This material is more suitable for insulating rooms from the inside.

- This material when insulated interior spaces It is dangerous to use when using a system of wooden or metal profiles and further covering with various decorative materials.

It is important to know

Laying foam sheets directly on the ground is not allowed: waterproofing work must first be carried out, and then a layer of screed must be poured. Otherwise, the floor may be damaged by rodents.

If all rules of use are followed, the service life of foam plastic as insulation reaches 100 years. This is its undoubted advantage.

Compliance with the rules for using polystyrene foam as insulation makes it possible to save money on heating your home, and also get rid of excess noise. It can also protect from the sun's hot rays, while preventing the outside walls from heating up. Therefore, there is no need to regularly use the air conditioner, which allows you to save on electricity.

Energy prices are constantly rising. And every family does not want to pay a lot of money for heating their home. And here a logical question arises - “What to do?” Get warm! In this case, heating costs will be significantly lower. And often, among the variety of insulation materials, people choose polystyrene foam.

Is it worth insulating walls with foam plastic?

Everyone decides this for themselves. And if you haven’t decided on this yet, it’s worth examining all the subtleties and nuances of using polystyrene foam as insulation. After all, there will always be both positive and negative aspects to this.

Polystyrene foam - cheaper and easier

It’s not in vain that many builders choose him, because he:

- easy to install (even beginners can handle it);

- is not expensive;

- has low weight;

- installation happens very quickly.

But many highlight its main disadvantage - increased flammability. However, this issue can be partially resolved by purchasing special brands of polystyrene foam marked “C” - self-extinguishing.

Is polystyrene foam harmful and what can it be used for insulation?

Increasingly, this material is used for insulation of residential premises. And the concept of environmental friendliness plays an important role here. As it heats up (more than +40 C) it begins to release harmful substance- styrene. That is why it is not recommended to use it for insulation. metal roof, and other similar heating elements.

Most builders advise against using it for interior work, but only for external ones. Moreover, this method of insulation has other advantages:

- the same geometry and usable area will be maintained;

- the freezing point will move to the outside of the house;

- fungus and mold will not form between the wall and the insulation;

- destructive environmental factors will not affect the walls of the house.

Polystyrene foam is good, but not always, and not everywhere

Of course, this material is good, but before you decide to use it in your home, you need to understand that it cannot be used everywhere.

So, he will cease to be good if:

- rodents live in the house;

- high humidity;

- poor ventilation.

Foam plastic - insulation not for private houses

As an example, let us give a situation where polystyrene foam was used to insulate a garage building that was adjacent to a private house. The joints of the plates were covered with polyurethane foam. This material performed its thermal insulation function perfectly. The room became noticeably warmer.

But after a short time, mice from the house made passages in it, in some places - right through. And the insulation work was ruined.

Foam plastic - high-quality insulation for walls

Apartment owners have long been convinced that if installation work By this insulation done efficiently, the wall will be dry in winter and cool in summer. The last factor does not mean that this material works as a cooler.

High-quality insulation of walls with foam plastic from the outside with step-by-step instructions

Even if a decision is made to insulate the walls, it is not always possible to find special tools. And this point also plays an important role when choosing the material with which these works will be performed.

As practice has shown, to install polystyrene foam according to external wall, you just need to adhere to a certain stage of work. Although there is an opinion about the simplicity of such work, irresponsibility can ruin all the work.

Stages of wall insulation with foam plastic:

1. Sheets of insulation are laid in a checkerboard pattern, so that the joint from one row falls in the middle of the sheet of the other row. All elements are carefully coated with glue.

2. If there are any unevenness on the butt seams, they need to be rubbed down to perfect condition.

3. We reinforce our structure to give it the required rigidity. To do this, we use a facade mesh, which we glue with a special mixture.

4. We strengthen it with a reinforcement mixture, which we apply in an additional layer after the reinforcing layer has dried.

5. We prime our walls.

6. We complete the work by applying a decorative layer: plaster, decorative slabs, facing brick and so on.

Polystyrene foam as insulation

Energy prices are constantly rising. And every family does not want to pay a lot of money for heating their home. And here a logical question arises - “What to do?” Get warm!

Polystyrene foam as insulation: application and cost

Among modern thermal insulation materials, the most popular is polystyrene foam or, scientifically speaking, expanded polystyrene foam. It is produced in the form of white slabs with a wide range of overall dimensions. The material is very light: the weight of one cubic meter, depending on the brand, ranges from 8 to 35 kg.

Properties of foam plastic as insulation

Today there are various types of insulation on sale. Which is better: polystyrene foam, mineral wool or other insulation?

Today there are various types of insulation on sale. Which is better: polystyrene foam, mineral wool or other insulation?

The wide demand for polystyrene foam is primarily due to low cost. However, this is not its only advantage. The light weight of the slabs, as well as the fact that they are rigid, unlike, for example, mineral wool, ensures simplicity and high speed of installation. Even one person can easily cope with this task without the use of any special technical devices, not to mention heavy equipment.

At the same time, polystyrene foam is a fairly effective heat insulator: its thermal conductivity coefficient is only 0.04 W/m*C (value for brands with medium density).

The technical characteristics of polystyrene foam as insulation make this material fragile. Depending on the circumstances, this quality can turn into either an advantage or a disadvantage. For example, due to its low strength, foam plastic is easy to process; it can be cut as desired directly during installation. On the other hand, when insulating a building from the outside, the material must be protected with a metal mesh and a layer of plaster. For the same reason, care should be taken during installation, since a foam board of any thickness is very easy to break.

Another enemy of polystyrene foam is ultraviolet radiation. In the absence of protection from solar radiation, the material quickly begins to crumble, becoming unusable. Contact with some paints and varnishes also contributes to the destruction of the foam structure.

The use of foam plastic for thermal insulation

Wall insulation

Polystyrene foam is widely used as insulation for external walls, and even owners of city apartments have begun to do this in the face of significant increases in energy prices.

Polystyrene foam is widely used as insulation for external walls, and even owners of city apartments have begun to do this in the face of significant increases in energy prices.

The polystyrene foam is screwed to the facade of the building with dowels, then plastered, after laying a metal mesh on top of it.

Another common option is:

- Polystyrene foam is laid in the spaces between the sheathing bars, the cross-section of which corresponds to the thickness of the slabs

- Siding panels are attached to the sheathing with seams sealed with foam

Polystyrene foam is also widely used as insulation for walls inside an apartment.

Insulation of basements and plinths

When insulating basements, foundations and plinths with foam plastic, the low strength of this heat insulator should be taken into account. In winter, it will experience significant loads from freezing soil, which, if unprotected, will lead to its deformation or destruction. For this reason, a brick or concrete lining is constructed outside the thermal insulation layer of foam plastic.

When insulating basements, foundations and plinths with foam plastic, the low strength of this heat insulator should be taken into account. In winter, it will experience significant loads from freezing soil, which, if unprotected, will lead to its deformation or destruction. For this reason, a brick or concrete lining is constructed outside the thermal insulation layer of foam plastic.

Floor insulation

The environmental friendliness of polystyrene foam has led to its widespread use inside buildings. For example, it is often used as a thermal insulator in floor construction. The polystyrene foam is laid on top of the waterproofing layer, filling the seams with polyurethane foam or silicone sealant. Then a screed and a finished floor covering are laid on top of the slabs.

The environmental friendliness of polystyrene foam has led to its widespread use inside buildings. For example, it is often used as a thermal insulator in floor construction. The polystyrene foam is laid on top of the waterproofing layer, filling the seams with polyurethane foam or silicone sealant. Then a screed and a finished floor covering are laid on top of the slabs.

Methods of roof insulation

Thermal insulation of roofs using foam plastic is carried out using one of two technologies:

Thermal insulation of roofs using foam plastic is carried out using one of two technologies:

- Installation of a non-ventilated (warm) roof. With this method, the roof is covered with 70 mm thick foam plastic slabs, which are then filled with bitumen

- Installation of a ventilated (cold) roof. In this case, the foam is attached to the inside of the roofing so that there is a ventilated gap through which water vapor will be removed

Is foam plastic harmful as insulation?

A significant disadvantage of polystyrene foam is the high danger it poses in the event of a fire. Manufacturers and marketers position this material as non-flammable and point to its ability to self-extinguish, which is especially evident in the presence of a fire retardant additive. However, a material does not have to ignite to be dangerous in a fire.

A significant disadvantage of polystyrene foam is the high danger it poses in the event of a fire. Manufacturers and marketers position this material as non-flammable and point to its ability to self-extinguish, which is especially evident in the presence of a fire retardant additive. However, a material does not have to ignite to be dangerous in a fire.

As experience and numerous tests have shown, exposure to flame and high temperatures provokes thermal decomposition processes in foam plastic, as a result of which the air, even at a considerable distance from the fire site, is filled with a large amount of smoke, corresponding in toxicity to substances of the highest hazard class.

There are a large number of insulation materials for the home. If foam is not your thing, then you may want to consider other options. For example, Rockwool insulation, specifications which can perfectly protect the house from heat loss. The structure of the material allows the walls to “breathe”, therefore, there will be no problems with rotting and fungus formation.

There are a large number of insulation materials for the home. If foam is not your thing, then you may want to consider other options. For example, Rockwool insulation, specifications which can perfectly protect the house from heat loss. The structure of the material allows the walls to “breathe”, therefore, there will be no problems with rotting and fungus formation.

Rockwool insulation is essentially mineral wool. If you only need to insulate the ceiling, we recommend that you familiarize yourself with the process of insulating the ceiling with mineral wool here. You can install this material yourself.

Here is the approximate price for polystyrene foam as insulation of various brands:

Here is the approximate price for polystyrene foam as insulation of various brands:

- PSB-S-15O (density - about 9 kg/cubic m): 1050 rub.

- PSB-S-25 (about 15 kg/cubic m): 1800 rub.

- PSB-S-25T (about 20 kg/cubic m): 2350 rub.

- PSB-S-35 Light (density - from 21 to 23 kg/cubic m): 2550 rub.

- PSB-S-35T (density - from 26 to 28 kg/cubic m): 3050 rub.

Reviews about polystyrene foam as insulation

Users unanimously recognize the most important advantage of polystyrene foam affordable price. Forum participants rate the thermal insulation qualities of polystyrene foam quite highly.

Users unanimously recognize the most important advantage of polystyrene foam affordable price. Forum participants rate the thermal insulation qualities of polystyrene foam quite highly.

But owners of private houses advise using this insulation only where there are no problems with mice. One of the users said that in the polystyrene foam he used to insulate the garage, these rodents made a whole system of passages, and their activity is accompanied by clearly audible sounds.

Foam plastic as insulation: use of the material in the construction of a thermal insulation layer of building structures

Brief characteristics of polystyrene foam as insulation. Scope of application of polystyrene foam as insulation. Is it dangerous to use foam plastic for residential insulation?

Polystyrene foam as insulation – its advantage and scope of application

Of all the thermal insulation materials available in their arsenal, builders most often choose foam plastic. Polystyrene foam has already been used as insulation for quite some time. for a long time for thermal insulation of both large construction projects and individual construction.

Many believe that this is one of the the best materials for thermal insulation of houses and other premises. Almost every material has its pros and cons; after considering them, we will understand whether polystyrene foam is really the best option for insulating rooms.

Characteristics of polystyrene foam as insulation

Polystyrene foam is a foam mass. Polystyrene foam slabs are distinguished by their low weight, since the inside is mainly filled with air. The raw materials from which polystyrene foam is made have even greater density than the original material. The main volume of polystyrene foam consists of still air, which is a good heat insulator.

Advantages of polystyrene foam as insulation

1. According to the hygienic conclusions of the manufacturers and in accordance with state standard polystyrene foam is environmentally friendly pure material. It is harmless to humans as it does not release toxic substances into the air.

2. In addition, this material has practically no shelf life, since it is not attacked by microorganisms and does not decompose. It has low thermal conductivity and has high vapor barrier properties.

3. Polystyrene foam is fireproof and fire resistant. When the temperature in the premises changes, it does not change its physical and chemical properties. Styrofoam High Quality contains a fire retardant that has self-extinguishing properties, as a result of which it does not support combustion.

4. The weight of this material is very low, and this is an additional plus, since it does not weigh down the structure and does not affect the shrinkage of the foundation.

5. It should be noted that this is an inexpensive material, easy to install in a building, and very durable.

Disadvantages of polystyrene foam

With all the positive properties of polystyrene foam, it also has a number of disadvantages.

1. Polystyrene foam has low mechanical strength, therefore, it is necessary to create additional protection for it.

2. In addition, it can be destroyed when nitro paints or paints with such a composition come into contact with it.

3. The disadvantages of polystyrene foam include its inability to allow air to pass through.

4. It may be susceptible to rodent attacks, so you need to cover it with a durable layer of plaster.

Insulation of walls with foam plastic

Polystyrene foam is good insulation for walls. The walls are insulated with foam plastic, both inside and outside. But most often, insulation is done from the outside. When insulating from the outside, it is possible to move the highest freezing point to outside walls, thereby preventing the cold from penetrating into the room.

It is not correct to carry out internal insulation of walls that face the street. The fact is that the wall that goes outside must warm up thanks to internal heating. When laying foam plastic on inner surface walls, the wall will be insulated on both sides, that is, the wall will not only be insulated from the outside, but it will also be thermally insulated on the inside of the room, which will prevent it from being heated using heating.

As a result, the “dew point” will shift inside the wall, or this point will end up between the wall and the foam layer. Moisture will accumulate in these places and saturate the wall; in addition, this moisture can freeze in cold weather, that is, all this will lead to a disruption in heat exchange, and the walls will gradually collapse.

That's why the best option, there will be insulation of the walls from the outside, but it will be necessary to finish the foam plastic on top with a layer of durable plaster. Polystyrene foam does not have increased mechanical strength, so strengthening the walls is necessary for the durability of the structure.

Insulation of external walls with polystyrene foam.

Floor insulation with foam plastic

Thermal insulation of the floor is also performed using foam boards. The use of foam plastic for floor insulation is very effective method, allowing you to keep the floors warm and reduce noise when walking on the floor or when moving furniture. IN in this case Foam plastic slabs with a thickness of up to 50 mm are used for thermal insulation of the floor. They are laid on a layer of material with insulating properties. Next, the seams are sealed, and only then everything is filled with screed.

Floor insulation with foam plastic.

Roof insulation

For thermal insulation of roofs in houses and buildings for various purposes, two methods are used: unventilated (warm roof) and ventilated (cold) roof. In the first case, when creating a non-ventilated (warm) roof, the entire roof is covered with 70 mm thick foam plastic slabs, and a bitumen layer is poured on top. With the second method, foam boards are installed on the back of the roof, leaving a ventilated surface to prevent the formation of water vapor. It is very important to properly insulate attic roofs.

Foundation thermal insulation

Insulating the foundation with polystyrene foam requires enhanced protection, since not only does soil pressure occur, but also the load on the foam plastic increases in winter during soil heaving, and this occurs during freezing. A strong reinforcement is required, for this purpose they produce brickwork or pour concrete.

Insulation of the foundation with polystyrene foam.

Thermal insulation of engineering systems

Foam plastic has become very often used for thermal insulation. engineering systems. For example, for thermal insulation of water pipes and sewer pipes during winter freezing, the use of polystyrene foam will be simply irreplaceable, as it will help to avoid the catastrophe of pipe breakage in the winter. Foam plastic is also used for thermal insulation of cold water supply pipes. Ventilation ducts, telephone lines and recessed ducts are also insulated with foam.

Polystyrene foam as insulation, its characteristics and scope of application Video

Polystyrene foam is widely used as insulation long time. However, polystyrene foam, like any other insulation material, has its advantages, disadvantages and a certain scope of application, which will be discussed in this article.

Foam plastic as insulation: reviews, disadvantages, service life

The problem of insulating a private house or apartment has always had to be solved, and effective methods arose only after the advent of such building materials as polystyrene foam. Insulating the ceiling, floor and walls with its help allows you to retain heat in your home and at the same time save money.

Polystyrene foam

There is pressed and non-pressed foam; it is not too difficult to distinguish them, even if you are not a professional. If you have ever looked at the structure of a material, you have most likely noticed that it consists of small balls that are interconnected, like a honeycomb in a beehive.

Pressless foam can be seen in boxes with household appliances, as it is actively used for packaging.

In terms of thermal insulation properties and appearance, the pressed one is practically no different from the second one; its granules adhere to each other somewhat more firmly, due to which it does not crumble. At the same time, pressed foam is more difficult to produce, which means it is more expensive, which is why it is less widespread.

Technical characteristics of polystyrene foam

This breathable material has a low specific gravity, does not accumulate moisture, and is not subject to rotting. Its main drawback is its flammability, although by applying plaster the home can be protected from fire.

Polystyrene foam characteristics:

- biological and chemical resistance to sea water, alkali, salt, soap, cement, bitumen, lime, gypsum;

- low thermal conductivity;

- resistance to temperature changes, due to which the material can be used in different climatic conditions;

- it is not a favorable environment for the development of fungi, mold and microorganisms;

- high vapor permeability - thanks to it, the moisture that accumulates in the walls evaporates;

- excellent soundproofing properties.

Basic properties of polystyrene foam as insulation

Expanded polystyrene is popularly called “foam plastic”. This word comes from the name of a Finnish company that supplied expanded polystyrene to the USSR. The name of the company was transformed over time into the name of this material.

At the moment, foam plastic is produced abroad and in Russia by various companies. The equipment for its production is cheap, and does not require skilled labor for maintenance and operation.

Now let's look at the properties of polystyrene foam:

Now let's move on to the use of polystyrene foam in low-rise private construction.

Foam insulation: simple and easy

It is done very simply. The polystyrene foam is attached to the wall of the building using special screws. Initially, you can level the wall using putty, attach the slab, then apply a layer of putty again and paint it. This way you get a completely flat wall.

Insulation of buildings from outside

Polystyrene foam as wall insulation is most often used outside. This method makes it possible to move the freezing point to the outer part of the wall, while preventing the cold from penetrating inside.

For this purpose, sheets with a thickness of 100 millimeters are used. They are attached using dowels and special glue. Performing these works at height is only possible using special equipment.

Internal insulation of the room

This method is less common than the previous one, although it is also effective. It is very convenient that it can be implemented regardless of the time of year and weather. But before insulating the walls inside, they must be pre-treated with special anti-mold compounds.

It should be taken into account that polystyrene foam as insulation reduces the usable area of the room. This is explained by the fact that it takes up quite a lot of space, especially considering that drywall is attached to the top.

Insulation of building walls

This method is applicable in the construction of 1- and 2-story houses. A wall 250 mm thick is erected, then sheets of foam plastic are laid, which are protected with plastic film, then the inner wall. This method has the advantage that polystyrene foam as wall insulation is completely protected from open fire and mechanical damage.

Insulation of floors

If we consider foam plastic as a floor insulation (reviews about this use can be seen mostly positive), it is important to take into account that its sheets are laid in a cement-sand liquid mortar during the screed. Air bubbles are expelled using vibration. A 50 mm screed is also made on top of the material.

These measures are especially necessary for residential buildings with damp basements. But in middle-floor apartments, foam plastic as floor insulation will also provide good sound insulation. In addition, this procedure is performed when laying a water-heated floor.

Insulation of ceilings

Such insulation is performed in the same way as with walls. The difference lies in the thickness of the sheets used: it should be no more than 50 mm. In a typical residential building, most apartments have low ceiling heights. Of course, if possible, you can increase the thickness of the foam.

This measure allows you to insulate the apartment, while reducing the noise level and making the home more comfortable.

Basement insulation with foam plastic

It will not be possible to use polystyrene foam in this case due to its hygroscopicity. At the same time, its thermal conductivity increases sharply, and its thermal insulation greatly decreases.

When polystyrene foam gets wet in the autumn and spring, the water in it turns into ice when it freezes, after which it breaks the material. After the first frost, wet polystyrene foam turns into dust, turning into separate balls that are unable to retain heat.

Base insulation with polystyrene foam

But for this it is quite possible to use this material. In this case, foam plastic as insulation is covered with a layer of plaster on top. The foam is attached to the base using plastic “fungi”, to which a fine metal mesh is then attached. Then plaster is applied to it and a decorative layer is applied on top - clinker brick, wild stone, facade tiles.

In this case, you can also use a metal profile for plaster to attach the foam. In this case, it is advisable to abandon the use of a system of wooden blocks. Practice shows that on the concrete base of the base, wooden blocks begin to rot from below, and moisture also gains access to the insulation.

Foam plastic for insulation of a wet facade system

On the facade of the house, the place of foam plastic is located under a layer of continuous decorative non-combustible coatings and plaster. When there is no access to oxygen and open fire, and there is no direct exposure to moisture, this material exhibits its best properties. Don’t forget about the reasonable cost, low thermal conductivity, and light weight.

Roof insulation

Here you need to understand where and what width of material to use. The “non-ventilated roof” is covered with 70 mm thick foam plastic, then a bitumen waterproof layer is laid on its surface. “Ventilated roof” involves installing slabs on the back side of the roof, while the ventilated cavity remains, preventing condensation.

Attic spaces can be excellent living rooms. At the same time, the thermal insulation of a gable roof brings great benefits at low costs. To do this, you need to install foam plastic in the cracks between the rafters.

Thermal insulation of pipelines

Until recently, the thermal insulation of engineering communications was not given much importance, and because of them, the share of heat loss is about 30%. For pipelines ventilation ducts, cold water supply, buried cables and telephone lines, today they are increasingly using foam plastic as insulation. This material is also used to protect sewer and water pipes from freezing. The undoubted advantage of using polystyrene foam for these purposes is the ability to give this material various shapes.

Where is it prohibited to use polystyrene foam as insulation?

- Expanded polystyrene cannot be used when insulating a bathhouse, since increased humidity and heating result in the emission of styrene.

- There is no need to insulate window slopes from the inside - for this it is advisable to use polyurethane foam. This material is more suitable for insulating rooms from the inside.

- It is dangerous to use this material when insulating interior spaces when a system of wooden or metal profiles and further cladding with various decorative materials are used.

It is important to know

Laying foam sheets directly on the ground is not allowed: waterproofing work must first be carried out, and then a layer of screed must be poured. Otherwise, the floor may be damaged by rodents.

If all rules of use are followed, the service life of foam plastic as insulation reaches 100 years. This is its undoubted advantage.

Compliance with the rules for using polystyrene foam as insulation makes it possible to save money on heating your home, and also get rid of excess noise. It can also protect from the sun's hot rays, while preventing the outside walls from heating up. Therefore, there is no need to regularly use the air conditioner, which allows you to save on electricity.

Foam plastic as insulation: reviews, disadvantages, service life

The problem of insulating a private house or apartment has always had to be solved, and effective methods arose only after the advent of such building materials as polystyrene foam. Insulating the ceiling, floor and walls with its help allows you to retain heat in your home and at the same time save money.

To ensure heat in the house, not only the roof, but also the walls should be insulated.

There is a whole range of materials for wall insulation on the market.

Walls can be insulated both outside and inside.

When insulating the walls from the outside, the living space area is preserved, and insulation technology makes it possible to provide the building with warm and modern walls.

Before you start insulating the walls, you need to decide on the insulation method. Lay or - individual preference. Each method has its own advantages and disadvantages. The features of each insulation method must be studied at the time of building design.

Insulation from the inside

Internal wall insulation is characterized by the following features:

- the cost of insulation from the inside is less than that of external insulation;

- season and weather do not affect the choice of time for work;

- there is no need to build additional scaffolding for insulation work.

Negative factors for internal insulation are:

- significant reduction in living space;

- the outer wall is insulated from heating from the room;

- the likelihood of fungus forming inside the wall increases, since the dew point is formed precisely in the inner part of the structure;

- when the heating is turned off, the walls quickly cool down due to the low inertia of the insulation;

- the junction of the ceiling with the external wall cannot be equipped with insulation, which leads to the formation of cold bridges.

The method of insulating walls from the outside is more popular despite the fact that the cost of labor and materials for performing the work is significantly higher than the method of internal insulation.

Dew point

Insulation from outside

The advantage of insulating walls from the outside is:

- in winter and in cold weather, heat is retained in the wall for a long time;

- the design area of the room is preserved;

- external thermal insulation protects interior walls from dampness.

Besides, external walls are additionally protected from weather conditions, which significantly increases the service life of the structure.

The main disadvantages of external thermal insulation of a structure are:

- restriction of work in accordance with weather conditions;

- increase in costs for materials used.

Which side of the wall to insulate with polystyrene foam?

It is advisable to insulate walls with expanded polystyrene from the outside, since the material does not allow air to pass through, which can lead to the formation of condensation inside the wall when internal insulation, and also indoors the material can emit a specific odor.

Advantages and disadvantages of expanded polystyrene

The polystyrene foam material is porous and air-containing  raw materials, is used in most cases as a heat-insulating material.

raw materials, is used in most cases as a heat-insulating material.

In industry, the material can also be used as electrical insulating and packaging material.

The material has become widely used due to its quality indicators:

- low level of water absorption;

- low thermal conductivity;

- ease;

- biological stability;

- durability;

- compressive strength;

- not affected by temperatures;

- ease of installation;

- low price of material.

Comparison of insulation materials

Despite the impressive list of positive indicators, Expanded polystyrene has disadvantages that must be taken into account during installation:

- low sound insulation;

- instability to solvents and many chemicals;

- afraid of fire. When burned, it releases harmful toxic substances;

- poor resistance to ultraviolet radiation;

- easily susceptible to the influence of rodents and insects, which, by making holes in the material, provoke its destruction;

- low vapor permeability;

- fragility.

However, the production technology of these materials is different: expanded polystyrene is produced by the extrusion method, when the granules melt when combined into a single structure, polystyrene foam - by gluing the granules with dry steam.

Specifications

Types of expanded polystyrene

Expanded polystyrene is classified according to the method of production of the material and the inclusion of various additives in it:

- pressed polystyrene foam. Produced by pressing;

- pressless expanded polystyrene. Produced by removing moisture by drying and then foaming high temperatures;

- Not much different from pressless; an extruder is additionally used in production. The best and best option for thermal insulation of walls.

There are other types of polystyrene foam (extruded, autoclaved), but they are not used as insulation materials because they have different characteristics.

In addition to types of expanded polystyrene, there are also various types of insulation, such as:

Wall pie when using insulation - polystyrene foam on the outside

A wall pie refers to layers of materials that are laid in a certain order, each of which performs its own functions to ensure a normal microclimate in the room.

When thermally insulating brick walls with polystyrene laid outside, The pie wall looks like this:

- interior plaster;

- outer wall;

- adhesive solution for gluing polystyrene foam;

- insulation (expanded polystyrene);

- adhesive solution for gluing the next layer;

- fiberglass mesh;

- adhesive composition;

- primer;

- finishing plaster.

NOTE!

When arranging a wall using polystyrene foam, It is necessary to lay the layers in strict sequence.

Internal and finishing plaster can be replaced with others finishing materials, which are provided for by design solutions.

Wall cake "wet"

Issues of vapor barrier and waterproofing

An important requirement during the construction and improvement of a house is the correct implementation of all work to ensure ventilation and waterproofing, since it is incorrect installation of these components significantly reduces the performance of the structure.

When insulating walls with polystyrene, waterproofing is not needed. It should be noted that with high flow groundwater Under the building, it is necessary to waterproof the basement and foundation.

Since polystyrene foam does not allow air and water to pass through, there is no need to lay a vapor barrier layer when insulating walls from the outside.

Wall insulation cake under siding

Sealing cracks and preparing sheathing

Installing polystyrene foam on the sheathing is the most labor-intensive process among the insulation options. Most often, sheathing is done in the case of finishing siding.

Sealing cracks

If you plan to install siding on the wall of a house made of beams, you must first seal the seams properly, clean the surface of dust and debris, and seal the cracks with sealants, polyurethane foam, or a mixture of sawdust and PVA.

If the wall is concrete, brick or foam blocks, then cracks in such houses are cleaned of sand, treated with a primer, then sealed as follows:

- if there is a small gap. Using a prepared mixture of cement and sand with the addition of PVA, seal the gap with a spatula;

- if the gap is medium size. Make holes for dowels at a distance of 20 cm. Using screws and washers, pull the metal mesh over the gap and seal it, pressing it into the mesh with plaster. Next apply the finishing layer;

- P ri big crack. Seal the gap with polyurethane foam, cut off any irregularities and seal it with two layers of plaster.

Large cracks can be repaired using anchors:

- knock down the plaster, seal the cracks with polyurethane foam;

- install a channel in the opening and attach a reinforcing mesh to it;

- you can use staples made of reinforcing mesh;

- apply plaster;

- putty.

Sealing cracks

When the wall is prepared for laying insulation, you can install the sheathing.

Preparing the sheathing

The sheathing for siding can be made from metal profile and from wooden beam . In humid climates, it is advisable to install metal slats.

Before you begin installing the sheathing, you should determine the location of the siding:

- with horizontal siding. The beam or metal profile is installed perpendicularly;

- with vertical siding. Frame boards or the metal profile is installed in a horizontal position.

The pitch of the sheathing is determined by the width of the polystyrene foam sheet: in width it should fit tightly between the sheathing slats and not form gaps.

The order of work is determined in steps:

- treat the wall with special mastic;

- frame boards are secured around the entire perimeter of the walls using galvanized screws and plastic dowels;

- if holes form between the timber and the wall, these gaps are sealed with pieces of polystyrene foam by gluing them to the wall.

CAREFULLY!

If the sheathing is made of wood, the boards must be pre-treated with antiseptic agents.

Lathing does not require special skills, but it should be noted that the choice of materials should be made based on climate conditions.

Lathing for siding

Wooden sheathing

Technology of wall insulation with polystyrene from the outside

Before you begin insulating the wall with polystyrene foam, you should dismantle the gutters, decorative elements, clean and prime the wall. Next, insulate the sills and window slopes.

Now let's talk about the thickness of polystyrene foam.

NOTE!

When insulating walls with extruded polystyrene, use sheets whose thickness ranges from 80 to 100 mm and more.

You can also use thinner sheets 30-40 mm thick if laid in two layers.

Let's start installing insulation on the walls with our own hands:

- a profile is installed at the bottom of the wall to hold polystyrene foam;

- the adhesive mixture is applied to the wall over the entire area in spots and onto the insulation sheet (amply on the center and edges of the sheet);

- tightly attach the sheet for gluing to the wall;

- Use dowels to secure the panel so that the dowel penetrates the wall at least 50 mm. The dowels are placed in the center of the panel and at the joints. It is recommended to use plastic nails;

- if gaps form (up to 2 cm), then they are sealed with mounting foam, if the gaps are larger, then they are first sealed with pieces of insulation, and then foamed. Excess foam is cut off;

- The heads of plastic nails are cleaned and puttied.

After installing the insulation, a reinforcing mesh is applied to the facade. You should cut strips of mesh at the corners and slopes and glue them with a spatula using an adhesive composition. Apply to the mesh along the wall adhesive composition so that it penetrates 0.1 cm through the mesh onto the polystyrene foam. If an overlap occurs, separate strips of mesh are placed on it and additionally glued.

Sectional view of the device

Fastening slabs with dowels

Application of assembly adhesive

After the surface has completely dried, it is leveled with fine granulation sandpaper.

Useful video

Detailed video instructions for insulating walls with extruded polystyrene foam:

In contact with

Advantages of insulating the walls of a house with polystyrene foam. How to choose the right insulation. “Wet” façade technology.

We insulate the house with polystyrene foam

The annual rise in energy prices and the desire to live in a cozy, warm home force owners of individual real estate to quickly insulate their buildings.

The article tells you how to choose the right polystyrene foam and insulate the walls yourself, what tools and consumables you will need.

Advantages and disadvantages

Foamed polystyrene - synthetic material, the positive properties of which make it an excellent insulation material. Advantages compared to other materials:

- Low specific gravity. One cubic meter foamed polystyrene weighs from 11 to 40 kg. This amount of material with a sheet thickness of 50 mm is enough to insulate 20 square meters. m. walls.

- Insignificant price compared to other insulation materials.

- Low thermal conductivity, contributing to energy saving in heating season and keeps you cool in summer.

- High levels of noise insulation, providing comfortable conditions in houses located along busy streets.

- Strength sufficient for mounting plates in a variety of ways.

- Easy installation.

- Available at any hardware store.

Among the shortcomings are noted:

- low vapor permeability;

- toxicity when heated;

- necessity exterior finishing to protect against direct impact sun rays(foam is destroyed by ultraviolet light).

What are the parameters for choosing polystyrene foam?

When choosing polystyrene foam, take into account the physical and technical characteristics that contribute to the performance of the functions assigned to the insulation:

When choosing polystyrene foam, take into account the physical and technical characteristics that contribute to the performance of the functions assigned to the insulation:

- preservation of heat (coolness);

- ease of installation;

- the chosen method of insulation;

- environmental friendliness for nature and safety for human health.

Let's take a closer look at the characteristics.

Slab thickness

In stores you can find sheets with a thickness of 10 to 100 mm in increments of 10 mm. The choice of thickness depends on the region and purpose of the building. Sheets of 40, 50, 100 mm are in demand and most often found in retail outlets, but the manufacturer is ready to produce products of 20, 60, 70, 80 up to 500 mm to order. The price will remain the same, calculated per cubic meter.

To simplify understanding, on average, foamed polystyrene with a thickness of 10 cm retains heat in the same way as timber with a thickness of 45 cm, foam concrete masonry with a thickness of 73 cm, Brick wall 150 cm or concrete 300 cm. This is enough to insulate walls in any region of the country.

Size

It is more difficult to choose the length and width of the sheets. Accepted here standard sizes 500x1000, 1000x1000 and rarely 1000x2000 mm. For installing insulation around windows and doorways sheets are cut sharp knife or a fine-tooth file.

It is more difficult to choose the length and width of the sheets. Accepted here standard sizes 500x1000, 1000x1000 and rarely 1000x2000 mm. For installing insulation around windows and doorways sheets are cut sharp knife or a fine-tooth file.

For large objects, electric cutters are purchased and made independently - this way the material crumbles less and the edges remain smooth, which is convenient for further finishing.

Density

The main parameter characterizing the scope of application is density.

For use in construction, manufacturers produce products of three varieties, which are conventionally designated by numbers in the name - 15, 25, 35. Their brief Comparative characteristics is given in the table.

Table. Characteristics different brands polystyrene foam

The low density of PSB-S-15 foam makes the sheets “loose” and easily destroyed. Small mechanical impact causes damage and leaves dents.

If we compare thermal conductivity, then the values for different types foam polystyrene do not differ much, unlike the price, so it’s not worth overpaying “for density”.

If we compare thermal conductivity, then the values for different types foam polystyrene do not differ much, unlike the price, so it’s not worth overpaying “for density”.

Flammability

Polystyrene foam burns only when exposed to open flame. The damping time (self-combustion) is 3 – 4 seconds.

At the same time, when polystyrene foam burns, highly toxic substances are released, causing death from suffocation.

If a fire occurs, you should leave the premises immediately.

Is it possible to use polystyrene foam on concrete walls?

One more important characteristic Any insulation is vapor permeable.

Polystyrene almost does not allow vapor to pass from the room to the street, but for insulating concrete walls this does not matter, since the materials are similar in performance. If the premises of a brick or expanded clay concrete house are humid, properly arranged ventilation solves the problem.

It is undesirable to insulate concrete walls from the inside for permanent housing. In cold weather, the dew point (freezing point) will move closer to inside, the walls will freeze through their entire thickness.

Internal insulation is beneficial for dachas that are not constantly heated. In this case, the building will warm up faster, since the house will become warm before the brick (stone, expanded clay concrete) walls warm up - the heat from heating devices, like in a thermos, it will hold the foam.

Which is better - polystyrene foam or polystyrene foam?

Foam plastic - foamed polystyrene. The name expanded polystyrene is commonly understood as extruded polystyrene, produced under the brands PENOPLEX, TECHNOPLEX, URSA.

Foam plastic - foamed polystyrene. The name expanded polystyrene is commonly understood as extruded polystyrene, produced under the brands PENOPLEX, TECHNOPLEX, URSA.

It has a higher density, the material is durable, and has grooves at the edges for a tight fit of the sheets. There is no crumbling when cutting, which reduces the amount of debris.

The price of extruded polystyrene is significantly higher than polystyrene foam, but main characteristic materials - thermal conductivity is comparable in terms of performance to PSB-25.

Among the advantages - the material is better resistant to moisture, which is important when insulating basements and ground floors. Installing penoplex on walls has no benefits compared to polystyrene foam.

Do-it-yourself technology for insulating external walls with polystyrene foam

A craftsman familiar with the basics of finishing work can insulate walls.

Let us consider in detail the insulation method called “wet facade”.

Tools

For work you will need hand and power tools:

For work you will need hand and power tools:

- level, plumb line, hammer, tape measure, pencil, hacksaw (knife), trowel and spatula;

- bucket for stirring glue and plaster;

- hammer drill or hammer drill with bits or drills for concrete;

- whisk attachments for drills for preparing solutions.

From Supplies acquire:

- glue for polystyrene on a cement or synthetic basis;

- dowels with a rod length 4-5 cm greater than the thickness of the foam;

- mounting foam or adhesive foam;

- foam gun.

Work progress step by step

Wall insulation begins with preparatory work:

- calculating the amount of insulation and its purchase;

You can calculate the area and amount of material by adding up the area of all external walls. When purchasing, 5% is added to the calculations possible mistakes when adjusting and at the joints of sheets on external corners walls, 6-7 special dowels are purchased for each square meter.

- preparing and checking instruments;

- purchases of consumables;

- installations scaffolding(if necessary).

The work is carried out in the following sequence:

The work is carried out in the following sequence:

- The surface of the walls is prepared and cleaned of dust and dirt.

- The voids in the seams (if any) are sealed cement mortar or foam.

- Level the surface with plaster so that unevenness does not exceed 1.5 - 2 cm. This will make it easier to fit the sheets and reduce the amount of expensive glue during further finishing.

- At a level of 50 cm from the ground, a support bar is attached strictly horizontally, if the foam is not placed to the ground, but finishing is provided with another material.

- Using a level and plumb line, markings are made.

- Apply a sheet according to the markings and through it (to avoid mistakes) drill a hole in the wall for the dowel.

- Starting from the central hole, fix the sheet to the wall.

Pin to flat surface polystyrene foam can be done using only dowels. For fastening to poorly plastered walls, a layer of glue is applied to the material plates and pressed against the wall. For reliability, you can fasten the dowels after a day.

When installing the first row, the level is precisely maintained. This will help avoid gaps when installing subsequent slabs.

- The second and subsequent sheets are placed offset (in a checkerboard pattern).

- The seams are sealed with polyurethane foam. Remove excess sealant after complete hardening, usually after 12 hours and up to 24 hours.

Instead of polyurethane foam, it is better to use adhesive foam - it has a lower coefficient of secondary expansion and adheres sheets better.

- Using a special toothed roller or other available means, punctures up to 0.5 - 1 cm deep are made on the surface of the foam for better adhesion to the layer of adhesive plaster.

- A 1-2 mm layer of specialized polystyrene foam adhesive is applied to the foam plastic, which is leveled with a spatula.

- A fiberglass mesh is applied to the glue and “sunk in.” The joints are overlapped, overlapping by 10 cm. The seams between the sheets and the edges of the mesh should not coincide.

- Level the glue with a spatula. By adding portions of glue in the right places, the final leveling of the surface is carried out, working as if using putty.

Finishing

After the composition has dried, prime the surface with products for external use.

After the composition has dried, prime the surface with products for external use.

Final finishing is carried out facade paint or use bark beetle plaster. The latter option is preferable, as it hides inaccuracies and irregularities, which are especially visible in side lighting.

At frame insulation There are no tricks. The foam is secured with wide-headed dowels between the frame slats. The remaining voids are filled with polyurethane foam or adhesive foam. Then they must be nailed to the frame waterproofing membrane. It is convenient to do this with counter-lattice bars, the thickness of which is 1-1.5 cm. After installing the siding or other material, there will be a gap between it and the foam, which will reduce the likelihood of dampening of the materials - the facade will become “ventilated”.

How long will it last

Foam plastic is resistant to moisture and aggressive substances of organic origin, so the service life before replacement is, according to manufacturers, 700 freeze-defrost cycles. This is significantly longer than the service life of the plaster layer, in which, in addition to the composition itself, the polymer mesh is destroyed.

Foam plastic is resistant to moisture and aggressive substances of organic origin, so the service life before replacement is, according to manufacturers, 700 freeze-defrost cycles. This is significantly longer than the service life of the plaster layer, in which, in addition to the composition itself, the polymer mesh is destroyed.

Based on the recommended operating parameters, you can expect the service life of external foam insulation to be from 20 to 40 years. It all depends on quality building materials and careful work carried out.

Insulation of house walls with polystyrene foam is one of the available ways keep warm in winter and cool in summer. A simple installation process that anyone can master makes insulation with foamed polystyrene a popular method that allows significant savings on the purchase of materials and wages for builders.

Useful video