The bathhouse must be warm, and the stove plays a key role in fulfilling this requirement. But no heating will be stable if high-quality insulation of the walls is not provided. And it has a number of features unfamiliar to those who have only insulated houses and ordinary outbuildings.

Peculiarities

Insulating walls from the inside is often enough for a private house or an ordinary non-residential building. But in the case of building a bathhouse, it is also required external finishing insulating layer. The approach depends largely on what kind of structural material is chosen for the walls of the bathhouse.

Also taken into account:

- climate of the region;

- year-round or periodic use of the bathhouse;

- required temperature;

- financial capabilities of customers.

Differences in the selection of insulation for different types of structures are associated not only with unequal heat capacity. Experienced builders take into account bearing capacity– if it is too small, the insulating material simply will not hold. In the case of log houses, shrinkage can lead to the formation of new cracks and the opening of old ones.

Species

There are dozens of types of insulation on the market, but for a bathhouse you can only use those that:

- safe in environmental and sanitary terms;

- excellent resistance to moisture;

- prevent bacteria and fungi from multiplying;

- maintain a stable shape for many years;

- and, of course, provide maximum heat retention.

Insulation with stone wool turns out to be the most effective solution, because no other material can provide such low thermal conductivity. Organic insulation materials have a long history of use and are undeniably safe. Shavings and sawdust, felt and flax tow do not exhaust their diversity. Modern industry has long established the production of slabs based on reeds, shavings or peat.

It is important to understand that such a solution is unacceptable in hot bath rooms.

Even the old one wooden sauna It is quite acceptable to insulate with polymer substances. So, foam is great for ceilings, it withstands contact with moisture and significant temperatures well. Machining different types of polystyrene foam is very light. Foam glass is most often used on the most problematic surfaces, when it is difficult to secure anything else.

Problems may be related to chemical composition– with significant heating, the release of toxic substances begins.

Often the choice again turns to basalt, dolomite or diabase wool.

These materials are suitable for cinder block, expanded clay concrete, and brick baths. They are not damaged by rodents, and installing the required layer is very simple.

Glass wool is even easier to install, but is not as resistant to high temperatures.

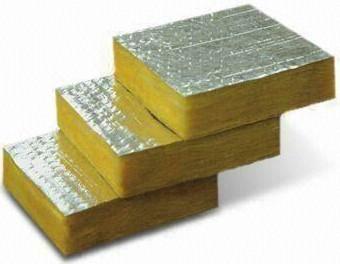

To avoid contact with moisture and to reflect heat inside, it is recommended to use foil.

Foil ready-made insulation is placed mainly on the ceiling and prevents the most important thing in it from leaving the steam room, that is, infrared rays.

In order to insulate chopped bath, various types of moss, hemp and jute have been used for centuries. But each type of such fiber causes a stir among birds and insects. The solution was found in combining them. The result is achieved due to the fact that the combined material is not recognized by animals as something familiar and is not pulled apart.

When using plant materials, high-quality drying is very important.

A bathhouse made of blocks needs to be insulated differently than buildings made of logs. The preferred solutions are fiberglass and mineral wool . Regardless of the type of insulation used and the main structures, requires careful vapor barrier.

A wooden sheathing must be installed on top of cinder block, gas block or gas silicate blocks.. Without it, no structures or insulation materials will stick to the surface.

The same approach in block construction is applied to finishing the ceiling. If fiberglass is used, It is strictly forbidden to cover both sides with foil. Otherwise, the passage of air and moist steam out will be disrupted.

A brick bathhouse is sometimes insulated with penoplex. But it only requires internal thermal insulation; there should be no finishing layers on the outside - this will only cause cost overruns on heating the masonry.

How to choose?

But the choice insulation material cannot be uniform for the entire bathhouse as a whole. There are too many differences between individual rooms. In addition to the washing and steam rooms, you also need to place a locker room and a dressing room inside (often these rooms are combined into one if there is not enough space). The air in the vestibule is always cooler than in other compartments.

Paints and plasters, which manufacturers proudly call heat-protective, do not provide enough high level thermal insulation, but can only be an auxiliary link in it.

Bulk material is used mainly for roofing and flooring. It is much more difficult to lay it inside the walls, and for this you definitely need a well masonry. Brick dressing rooms are mainly insulated with foam plastic due to its ideal compliance with the required parameters and affordable price.

Frame fastening of insulation according to wooden beam produced for finishing:

- clapboard;

- plastic panels;

- boards;

- corrugated sheets and siding.

The installation pitch of the frame is determined by the width of the cladding being created. Considering the inevitable crumbling of foam when cutting, a certain supply of material should be reserved.

If the air humidity in the sauna waiting room is relatively low, it is permissible to use mineral wool. They attach it in the same way as polystyrene foam. If the spaces between the racks are occupied by communications, a layer of unedged board is placed above the frame, and thermal protection is mounted on it.

Internal insulation of dressing rooms is most often done with penofol, which stops 97% of thermal energy.

Considering the insignificant thickness, such a coating will allow for the most efficient use of useful areas. Where heating devices are attached, penofol should be left unfinished. It can also be used as part of underfloor heating. Laid out under pipes or electric cable, penofol increases heating efficiency.

When forming slab foundation the dressing room is insulated using wooden joists. The timber is connected to the slab using self-tapping screws; the gaps must be filled 100%.

In case of equipment pile foundation All structures are installed on beams made of steel or wood. They are treated, respectively, with antiseptics or anti-corrosion mixtures. The insulating layer must be covered with a vapor barrier in the form of a membrane that stops the condensation of steam inside the thermal protection.

The requirements for thermal insulation in a steam room will be significantly higher, but the following will help reduce the need for it:

- installation of solid double-glazed windows;

- formation of a high threshold with a low door;

- purchasing not a simple stove, but a heater;

- carefully thought out bathhouse configuration;

- high-quality ventilation.

Waterproofing material for a steam room it should easily tolerate even very intense heating. Kraft paper copes well with this task. The walls of the steam rooms are insulated with sphagnum (placed in the gaps of the crowns) and tow (bridging the cracks). Actually, insulation is achieved using building moss, extruded polystyrene foam, polystyrene foam and penoplex.

Advantage synthetic materials are:

- resistance to mechanical destruction;

- long period of work;

- excellent heat retention.

The steam rooms of frame baths are in many cases insulated with basalt wool.

It is chosen both because of its excellent practical qualities and because of its low cost. Expanded clay is also inexpensive, but it will have to be poured at least 30 cm inside the walls, which significantly complicates the work.

Ceilings can be insulated with clay; if they are filled with sawdust, soil must be placed on top of the insulation layer to guarantee fire safety. From modern solutions experts recommend basalite, isospan or overlapping layers of plain foil.

Insulation scheme

When the means for insulating the bath are selected, you need to figure out how best to insulate the room with their help. Wooden walls should be covered with foil vapor barrier. Moreover Foamed polyethylene with an outer aluminum layer will not work, you need strictly clean foil. It is nailed directly to the wood sheathing. An overlap of at least 10 cm is made at the joints; it must be glued with aluminum tape for maximum tightness. Planks are required to be used for fastening interior trim parts.

A similar scheme is practiced in buildings made of gas silicate and foam concrete blocks, and brick. When working outside, the list of acceptable insulation materials is much larger than inside, because the health risk is noticeably reduced.

External thermal insulation is carried out during construction, the first step is to work with the foundation. If you do it later, you will need to break the blind area and then create it again.

It is not advisable to insulate the base and plinth with foil materials– they are too thin and do not allow you to achieve the desired effect. Mineral wool is also not suitable, it deteriorates too easily when exposed to water.

Slab insulation must also be laid under the blind area to prevent freezing of the soil next to the building. Concrete blind area and the external finishing of the base are formed only after this.

If polystyrene foam and other synthetic insulation materials are installed correctly, they can even be placed in the floor of a bathhouse.

The right step becomes preparation concrete screed, completely isolating the insulating layer from the inside of the room. Start by creating inclined surface, on top of which a layer of waterproofing is laid, followed by insulation. Then a vapor barrier film is laid out to serve as a base for the concrete. The middle part of the structure must be equipped with a ladder with a drainage pipe.

More simple solution It turns out to be mixing concrete with polystyrene foam or vermiculite.

This step allows you to obtain a layer that is both strong and heat-retaining, which will eliminate the need to place entire slabs under the screed.

If you use expanded clay, you won’t have to worry about insulation from the internal volume of the bathhouse at all.. The mineral is poured into the void separating the finished floor from the subfloor; in another embodiment, it is laid out around brick columns. Since expanded clay gets wet easily, you need to take care of powerful ventilation, which will contribute to its accelerated drying. You can choose expanded clay for insulating bath ceilings under cold roof, as long as the filing is strong enough.

Insulating attics above steam rooms using sawdust is permissible only after mixing it with clay.

The formed solution is laid out between the lags. Otherwise, the vapors coming from below will saturate the lined insulator and worsen its characteristics. The combination of sawdust and cement recommended for ordinary houses cannot be used. because it spoils too quickly.

It is important not to forget about insulation entrance doors using felt padding, thermal curtains or foam covering.

How to calculate the required amount of material?

When the scheme of work and the type of material used are completely clear, it is time to evaluate the thickness of the created cake based on thermal calculations. Only specialists can carry them out competently, so there is no shame in turning to them for help for ordinary customers and amateur builders.

To ensure that the inner and outer layers of thermal protection match necessary requirements, you need to take into account a number of nuances:

- total area;

- useful area (the one through which steam circulates);

- number of premises;

- climatic conditions;

- type and thickness of construction materials;

- the strength and direction of prevailing winds;

- the type of bath and the level of air humidity in it.

Work order

When insulating a bathhouse with your own hands, you will definitely need a hammer, a wood saw, a drill and a hammer. If you are going to use it for internal lining wood, it is recommended to use alder or linden board. They perfectly resist contact with water and do not heat up even in overheated air.

The walls are insulated first, and for this purpose the sheathing is invariably stuffed. It can be either wooden or aluminum.

The next step in the step-by-step instructions is the installation of the frame, which will guarantee reliable ventilation. It is advisable to install the frame vertically so that the lowest parts of the skin are horizontal and can be easily replaced.

A vapor barrier layer is placed on top of the roll or slab insulation, secured to slats approximately 0.3 cm thick each. Next comes the turn of the cladding. The lining is fastened with clamps or clips, and the boards are nailed down with galvanized nails, driven tightly using a hammer.

The ceiling should definitely be insulated. Most often, such work is carried out outside, but when using a pitched roof it will be too labor-intensive. Then the finishing is done inside, the sequence of steps is the same as when working with walls. The difference is that it is necessary to attach the slabs to the “fungi”. The insulation cannot be installed in a layer thinner than 0.2 m, because otherwise the ceiling will cool down the steam room too much. The vapor barrier overlap should have a similar size.

A slatted frame is also installed inside the brick bathhouse. Instead of mineral wool, penotherm is often placed in it– it is more reliable and does not deteriorate so quickly under the influence of water. The joining points are covered with thin but relatively strong slats.

Even careful selection of material and strict adherence to standardized technology may not be successful. This is most often due to ignoring subtle nuances that are not obvious at first. The outer edges of the foundation should be provided ventilation holes, then the water will not collect below, creating a center of cold.

To improve the vapor barrier properties of kraft paper, it is recommended to cover it with a mixture of sawdust and clay or other similar materials. Experts recommend carefully inspecting the perimeter of the windows, especially the part under the window sill - this is where cracks most often appear that require covering with insulation.

When choosing doors for the entrance to the steam room, you need to make sure that they do not have gaps and are thoroughly fitted.

Those suffering from allergies and breathing disorders should avoid using glass wool. Even the slightest chance of it entering the body outweighs positive qualities this insulator.

Ecological wool is less dangerous, but too sensitive to the harmful effects of water. When selecting materials with improved environmental and sanitary characteristics, you should always find out how great the risk of their ignition or the occurrence of mold outbreaks is.

Insulating a bathhouse is too important a job to violate the manufacturer’s instructions. You should become fully familiar with them before starting work. If foil material is mounted, it must be placed with the metallized film inside. It is unacceptable to install insulation thicker than the installed bars. You should also not violate standard order arrangement of layers.

Fastening to a wooden wall is best done with nails rather than self-tapping screws.

It is recommended to leave a gap of 0.8-1.2 cm from the insulating material to the finished surface to ensure internal air circulation. The thermal protection layer near the ceiling should be thicker than on the walls. Whenever possible, it is better to lay the material on this ceiling from above, rather than from below. Waterproofing under the floor is most often created using roofing felt or rigid polyethylene.

The final filling of the floor must be done as carefully as possible, because the slightest penetration of moisture into the insulating layer is completely unacceptable. If expanded clay is used, it should be twice as thick under the floor as in the walls, and this is the minimum.

Sealing windows with jute or any other fiber is much more practical than using silicone sealant. Even in places with a comfortable climate, it is recommended to make thermal protection with a pair of at least 150 mm thick.

It is not advisable to use roofing felt and glassine for thermal insulation inside. The most convenient foil for work has a thickness of 65 microns.

Concrete and brick baths are most often covered on the outside with a layer of soft thermal insulation (produced in the form of mats). Foil must be placed on top, and then the finishing material is installed. At the very bottom, it is recommended to install a profile in the shape of the letter P, which will prevent the insulation from sliding off the wall and thereby increase the reliability of the structure.

The microclimate in the bathhouse is unique. Competent arrangement construction involves insulating the bathhouse inside. This process is labor-intensive, but completely doable on your own.

Information on how to properly insulate a bathhouse inside will allow the owner to significantly improve its performance. After completing the work, you will be able to save on fuel and ensure the safety of thermal energy in the room.

When deciding how to insulate a wooden bathhouse from the inside with your own hands, you should take into account a number of factors:

- properties of the material used to provide thermal protection;

- personal construction skills and capabilities;

- own preferences.

Features of materials for thermal protection

To decide how and how best to insulate a bathhouse from the inside, you need to know the conditions under which the materials will be used:

- First of all, you need to take into account that the air is different in both the steam room and the washing room. high humidity. It is unlikely to be dry in the dressing room. Taking these factors into account, we can conclude: you need to choose a non-hygroscopic insulation or the material must have reliable vapor and waterproofing. Thermal insulation for a steam room bath must be of high quality.

- In the steam room, the air temperature often reaches more than 100 degrees. Insulation materials such as extruded polystyrene and polystyrene foam, under conditions of strong heating, will begin to release substances harmful to human health. For the same reason, plastic panels and linoleum cannot be used to decorate the steam room. In the first case, the products are subject to deformation even at 80 degrees of heat.

- A significant part of the thermal energy under high temperature conditions begins to be lost both due to heat exchange and in the form of thermal radiation. To prevent heat loss, the insulation for the bathhouse on the inside walls must have a foil surface or a reflective layer consisting of foil must be provided in the thermal insulation scheme.

Insulation of different types of walls

The choice of how to insulate the walls of a bathhouse from the inside depends on the type of material from which it is built:

- If it is brick, stone or concrete products, thermal protection is required. The fact is that when there is no thermal insulation, the bathhouse will have wet walls and, as a result of temperature fluctuations, they will quickly begin to collapse. The thickness of the insulation should be selected taking into account the parameters load-bearing structures and climate in the region. Most often, experts recommend a 10-centimeter layer.

- Is it necessary to insulate a wooden bath?? On the one hand, the thermal protection of the building will not hurt, but on the other hand, wood can be called one of the best materials for the walls of the steam room and dressing room. Of course, insulation is required for baths made of timber, with walls no more than 15 centimeters thick. Sauna log buildings are thermally insulated when the cross-section of the log does not exceed 20 centimeters.

On the inside, walls of greater thickness are either not insulated, or thermal protection is provided with waterproofing and clapboard finishing. Lathing is only suitable if there are rubble on the walls.

Horizontally located strips of vapor barrier are fastened with a stapler with a 5-centimeter overlap to prevent water from penetrating under the material. First, the lower fabrics are hemmed. Polyethylene should not be used for vapor barrier due to high temperatures.

Selection of insulation materials

The optimal solution for insulating a bathhouse from the inside is considered to be basalt wool. Hard mats of 10 cm thickness are used. When thermally protecting the ceiling, the thickness of the thermal insulation layer should be about 15-20 centimeters, since heat loss mainly occurs through the ceiling.

To insulate the bathhouse inside, you still need to have the following materials at your disposal:

- For sheathing. Most reliable option for bath buildings made of brick or stone - construction of a frame from a profile used for plasterboard (read: ""). Often the CD ceiling profile is chosen, and the UD guide profile is used to make edging along the perimeter of the walls. The fixation step for direct hangers is from 60 to 80 centimeters. The gap between the profiles must be made smaller by 1-2 centimeters compared to the width of the insulation boards. IN wooden baths bars are used as a profile.

- For water vapor barrier. A heat-resistant material with foil is required that is impermeable to moisture and steam. The construction market has large selection such products. For example, you can purchase foamed foil polypropylene, designed for temperatures up to 150 degrees. This material is able to protect the walls of the room from dampness and reflect radiant heat, thereby reducing heat loss. So a layer of Penotherm with a thickness of 3 millimeters provides the degree of thermal protection as a 150-mm beam.

- For finishing . Usually the insulation is placed in the bathhouse under the lining, as in the photo. This material is produced for final finishing from linden or aspen, since products from these wood species are resistant to decay processes, do not heat up even at high temperatures, and retain their original appearance for a long time.

Thermal insulation of floors, windows and doors

When deciding how to insulate a bathhouse inside with your own hands, take into account the possibility of increasing the degree of thermal resistance in ceiling and walls. True, a cool floor and the presence of drafts also take away a lot of heat.

To thermally insulate the door leading to the steam room, a thick felt frame is attached to it, which will reliably cover the cracks. Wooden frames at the windows located in the steam room, dressing room and washing room are insulated with cotton wool.

As for plastic, it is not installed in places with high temperatures, but in other rooms there is no need to be afraid that polymers will undergo thermal decomposition. Self-adhesive foam strips are used to protect plastic windows.

The choice of products, the better to insulate the bathhouse inside, depends on the type of floor covering. Expanded clay is poured onto the surface of the leaking wooden floor, and boards are mounted on top of the leveled backfill. It will be useful to understand how to insulate a bathhouse made of expanded clay concrete blocks from the inside so that problems do not arise later.

They begin to equip the concrete leaking floor by digging a pit 50 centimeters deep.

The layers of the thermal insulation structure are arranged from bottom to top in the following sequence:

- sand –5 centimeters;

- polystyrene foam – 20 centimeters;

- concrete mixed in a 1:1 ratio with foam chips - 5 centimeters;

- waterproofing;

- concrete combined with vermiculite in a 1:1 ratio (this is the name of a natural material with low thermal conductivity) – 5 centimeters;

- reinforced screed –5 centimeters.

During the process of pouring the base, it is necessary to arrange a slope. A boardwalk is installed on top of the concrete screed on the joists.

In the case when you need a continuous flooring, a heat-insulating material is laid on top of the rough base in a layer of 10-20 centimeters, this can be mineral wool or polystyrene foam. Then it is covered with waterproofing, not forgetting to overlap the walls. Mount on top of this layer reinforced screed 5-10 centimeters high.

Then, as a rule, the tiles are laid. Despite the fact that the tiles in the steam room do not heat up to a high temperature, it is advisable to provide wooden coasters for your feet to make your visit to the bathhouse more enjoyable.

Arrangement of thermal protection of walls and ceilings

Insulating the walls and ceiling of a bathhouse from the inside is similar to how it is done in other rooms, while special attention You should pay attention to the reliability of laying the vapor barrier layer.

Stage one - creating the sheathing. The procedure for how to insulate the ceiling in a bathhouse from the inside suggests that the distance from the sheathing to the base of the wall or ceiling needs to be made slightly greater than the thickness of the material for thermal insulation.

When using galvanized profiles, this gap is adjusted using hangers, and the block is nailed down using a backing, which can be a piece of block. Galvanized hangers are also used for wooden sheathing.

The sequence for attaching the profile is as follows:

- A UD guide profile is fixed along the perimeter of the walls or ceiling, observing a 60-centimeter step. It is mounted to timber or logs with self-tapping screws, and to brick or concrete walls - with screws and plastic dowels.

- The axes of the CD profiles are marked, taking into account that the gap between them should allow the laying of heat insulation slabs without trimming. Then the hangers are attached to the wall, observing a step of 60-80 centimeters.

- To install and fix the CD profiles to the hangers, use metal screws 9 millimeters long. The free edges of the hangers need to be folded.

Stage two - installation of insulation. Basalt wool in slabs is placed between the bars (profiles). Insulation of a ventilated façade or loggias is carried out in a similar way. The work must be done in a respirator (gauze bandage) and special glasses. The fact is that small fibers of this material They are volatile and, upon contact with the human mucous membrane, strongly irritate it.

For cutting slabs use a standard sharp knife. The insulation should not be crushed during installation. Regarding how best to insulate a bathhouse, you need to know that with a constant weight of the material, the smaller its volume, the worse its heat-insulating qualities will be.

Stage three - vapor and waterproofing device. Strips of material are fixed horizontally from bottom to top, maintaining a 5-centimeter overlap. The foil side of the insulation should be facing inside the room.

The method of fixing the vapor barrier depends on the material from which the sheathing is made. So, before you insulate the steam room in a log bath, you need to stock up on a construction stapler. If there is a galvanized profile, the strips are secured with double-sided aluminum tape.

To create a high-quality vapor barrier, the insulation not only needs to be fixed, all existing joints must be taped with the same tape. Then moisture will not be able to penetrate the insulation.

Stage four - paneling. To make the room cozy and beautiful after completion of insulation, it is necessary to finish the walls.

First, prepare the tools and materials necessary for the work, including:

- circular saw or electric jigsaw;

- drill - screwdriver;

- rasp (required when adjusting and processing the edge of the lining);

- construction square (necessary for marking boards);

- level and plumb line (they are in demand when checking verticals and horizontals);

- metal clamps for fixing wooden lining;

- copper or galvanized screws, which are needed for fastening the clamps to the bars;

- metal screws;

- wooden baseboards for finishing corners.

When carrying out work, you need to consider a number of points:

There should be a small gap between the lining and the vapor barrier layer. In addition, gaps (no more than 1-2 centimeters) are installed along the edges of the ceiling, as well as in the upper and lower parts of the walls.

The end boards in each row of the lining should be fastened with screws through and through, and their caps will be covered by the baseboard. All other boards will be held in place by clamps.

The above-described procedure for carrying out work allows you to both insulate an old bathhouse from the inside and absolutely new building. Thermal protection of a bath structure is a very important stage, since the efficiency of the steam room depends on its quality. The main thing in the work is to take into account the slightest nuances and then the result will exceed expectations.

Internal insulation of a bathhouse is one of the most important stages arrangement of this building. Without high-quality thermal insulation, the owner will have to spend much more resources on heating the steam room, and the atmosphere in the bathhouse itself without properly installed protection will leave much to be desired.

Since ancient times in Rus', moss, felt and even flax have been used to insulate baths, mainly due to the lack of other insulation materials - plant fiber either rots or dries, so today it is not used for basic thermal insulation.

Red moss - insulation

The main difference between insulating a bathhouse and a similar event in an ordinary house simple: in the steam room you need to maintain the heat for as long as possible, i.e. the high temperature should remain indoors for as long as possible.

Thermal insulation work in a bathhouse can be carried out using a wide variety of materials. For example, the ideal solution is modern insulation based on stone wool with an applied foil coating - it does not burn, can withstand temperatures up to 750 degrees, effectively retains heat, does not rot, and is not of interest to rodents.

After reading the information below, you will get a complete theoretical understanding of the process of performing internal insulation of a steam room, and also study step-by-step instructions for self-installation thermal insulation materials.

Any construction, repair and finishing activities begin with the preparation of materials, without which the implementation of the planned work will simply be impossible. Pay due attention to studying the list below: it is better to spend a little time reading and immediately buy everything you need, than to later return to the store and buy more of what you forgot.

Insulation

The main component of the list under consideration. Modern market offers a wide range of thermal insulation materials, but not all of them are suitable for use in a steam room - humidity and temperature may be too much for you. For bath insulation, the following are most often used: expanded clay (floor insulation), materials based on stone wool, as well as expanded polystyrene.

Important! It is strongly not recommended to use polystyrene foam to insulate the steam room itself - at high temperatures, material of dubious quality can most likely emit substances harmful to human health.

Comparative characteristics of the mentioned materials are given in the following table.

Table. Comparison of popular bath insulation

| Evaluation criterion | |||

|---|---|---|---|

| Structure | Bulk material natural origin. Presented in the form of granules with a cellular structure. | Fibrous structure. The arrangement of fibers is both vertical and horizontal, disordered. | Open cellular structure. |

| Moisture permeability | The material does not allow water to pass through. | Mineral wool insulation has virtually no tendency to absorb moisture. | Moisture permeability is extremely low. |

| Weight | Easy | Medium-light | Easy |

| Strength | High | Average | Average |

| Compression resistance | High | From low to medium, depending on the specific type of material and manufacturer technology. | Average |

| Toxicity | The material is safe | No toxic properties | Over time, it begins to release harmful substances |

| Possibility of use under high load conditions | Suitable | Depending on the brand of material | Not suitable |

| Tendency to decay | The material retains its original integrity for a long time | Durable insulation | Has a tendency to decay |

| UV resistance | Does not react in any way to exposure to sunlight | Characterized by high resistance to ultraviolet radiation | Prolonged direct contact with sunlight has an extremely negative effect on performance characteristics material |

As noted, expanded clay is suitable for insulating bath floors. Bulk material allows you to provide the required thermal insulation of both wooden and concrete structures. Mineral wool insulation is optimal for insulating both walls and ceilings. The best option, as noted, is a thermal insulation material based on stone wool, equipped with an additional foil coating - the key characteristics of such insulation at a higher level.

Prices for mineral wool

mineral wool

In accordance with the current provisions of the technology for carrying out the work in question, the joints of the insulation boards must be glued with foil tape. This will create a sealed surface with the highest thermal insulation properties.

Prices for foil tape

foil tape

Elements thermal insulation coating are placed in the cells of a pre-assembled sheathing, for the assembly of which wooden blocks are used. Select the section of the beams in accordance with the thickness of the thermal insulation. For example, if you are installing a 10-centimeter thermal insulation layer, use bars with a similar thickness or width to assemble the frame.

Choose the distance between the bars 1-2 cm less than the width of the slabs or roll of insulation. For bulk materials optimal distance between bars – 45-60 cm.

The sheathing elements (bars) are fixed using dowels/screws (if the surface is wooden) or anchors (if the base is stone). The length of the fasteners is also selected in accordance with the base material: for wood - 2-2.5 cm, for permanent structures - from 4 cm.

The specific length of fasteners is determined in accordance with the characteristics of their use. For example, during the installation of sheathing, the fasteners must be of such length that they ensure high-quality fixation of the beam/profile of the selected section. The cross-section of the beam itself, as well as the profile parameters, are determined in accordance with the thickness of the thermal insulation layer being installed.

Additional materials

If you insulate a bath using a material other than foiled mineral wool, you will additionally have to purchase a water vapor barrier film.

If you plan to pour a concrete screed, the set for work will increase to include the following items:

- reinforcing mesh;

- mixture for pouring screed or materials for it self-cooking(cement, sand, water);

- lighthouses;

- damper tape;

- polyethylene.

Prices for water vapor barrier film

water vapor barrier film

The floors in the bathhouse can be wooden or concrete. The technology for arranging the direct thermal insulation layer does not have any special differences depending on the flooring material, except in the case of concrete structure you will have to pour more expanded clay.

The thickness of the backfill is usually determined in accordance with the thickness of the walls. On average, a layer of expanded clay is poured at least 2 times thicker than the walls. If the height of the room allows, the thickness of the backfill can be further increased - this will help improve the efficiency of insulation.

First, for greater convenience of work and subsequently more accurate control of the evenness of the backfill, mark the base. To do this, it is enough to divide it with parallel lines into sections up to 1 m wide or along the length of the rule you use.

Important! If you are insulating a floor on the ground, at the very beginning, even before marking, you need to do the following:

- thoroughly compact the soil inside the foundation (if the foundation design assumes the presence of “free” soil, for example, in the case of strip supports);

- cover the walls with impregnation for waterproofing;

- cover the soil with a 10-centimeter layer of sand, spill it with water and compact it thoroughly;

- cover the sand with roofing felt with a 15-centimeter overlap on the walls. Also lay individual sheets of roofing felt with a 15-centimeter overlap. For fastening, use waterproof construction tape.

The exact procedure for insulating the floor with expanded clay, with illustrations and necessary explanations, is given in the following table.

Table. Insulation of a bath floor with expanded clay

| Stage | Illustration | Necessary clarifications |

|---|---|---|

| The film must be stretched so that its edges along the wall are higher than the floor level. If the base is already covered with roofing felt, there is no need to lay the film. |

|

| For example, a profile for drywall is suitable. The guides are set in accordance with the previously applied markings and secured in a suitable way, for example, with screws or nails. | |

| Align the beacons by level. In the future, these auxiliary devices will help you fill up the most even layer of expanded clay, which will ensure best quality carrying out further planned work. Determine the installation height of the guides in accordance with the required thickness of the thermal insulation layer. Many developers do without guides, but this is a less convenient and accurate option. |

|

| Pour expanded clay |

| The previously installed guides will help you do this as efficiently as possible. |

| For leveling, we use a rule or an ordinary strip of suitable length. | |

| To make leveling the insulation more convenient, we can use various auxiliary devices. For example, a rake will come in handy in large areas. |

The floor is insulated and ready for further arrangement in accordance with the developer's plans. At the discretion of the owner, additional thermal insulation material, for example, mineral wool or expanded polystyrene, can be laid on top of the expanded clay.

As an example, a diagram of a concrete floor equipped with expanded clay for thermal insulation is given.

Video - Floor insulation with expanded clay

Insulation of bath walls and ceilings

Wall insulation schemes will vary slightly depending on the material of manufacture. Information on this matter is presented in the following table.

Table. Wall insulation schemes

| Material of manufacture | Scheme |

|---|---|

|

|

1 – wall, 2 – thermal insulation, 3 – sheathing, 4 – cladding, 5 – ventilation gap. |

|

|

Sequence thermal insulation works remains the same for walls made of any materials: if necessary, a water vapor barrier film is attached, sheathing bars are mounted, insulation is placed in the resulting cells, another layer of water vapor barrier is fixed on top (if necessary), sheathing slats are nailed for the finishing sheathing (at the same time they will provide the required ventilation gap), the selected finishing material (usually lining) is installed.

The ceiling is insulated in a similar sequence. An example of a ceiling insulation scheme is shown in the following image.

Information regarding step-by-step insulation of the walls and ceiling of the bathhouse is given in the following table.

Important! Insulation will be carried out with mineral wool material with a foil layer, which eliminates the need for preliminary attachment to the surface of the hydro vapor barrier material. The operating procedure is discussed using an example wooden surfaces. Regarding concrete walls and floors, the recommendations are the same, the only thing is that you need to use other fasteners and for greater convenience, the wooden guides can be replaced with a metal profile.

Table. The procedure for insulating walls and ceilings in a bathhouse from the inside

| Work stage | Illustration | Necessary clarifications |

|---|---|---|

| Information regarding the elements used to construct the frame, as well as fasteners for fixing the guides in different cases was given earlier. The mounting step of the guides is selected in accordance with the width of the insulation. Typically this is about 60 cm, but can be reduced to 59-59.5 cm so that the thermal insulation elements fit as tightly as possible. |

|

| Rules for laying slabs |

| Be sure to put on gloves first - contact of “bare” skin with mineral wool does not give the most pleasant sensation. We place the foil material inside the room with foil - thanks to this, the heat will not only be retained, but will also be additionally reflected into the steam room. |

| The slabs are installed vertically into the frame and do not require additional mechanical fastening. | |

| Installation of slabs on the wall |

Installation of slabs on the wall | The sequence and recommendations for insulating walls and ceilings are similar. To insulate the partition separating the steam room from the adjacent room, a layer 50 mm thick is usually sufficient. |

| Thermal insulation external wall requires a thicker layer - 100-150 mm (in regions with a particularly cold climate - up to 200 mm). | |

| To save money, the insulation can be made in two layers, with one layer made of ordinary mineral wool, and the second, which will “look” into the room, made of foil-coated material. | |

| The use of such insulation, as noted, eliminates the need to use additional water vapor barrier materials. |

|

| Having filled the frame with heat-insulating boards, we glue the seams and joints with foil tape. | |

| A 1-2 cm gap is enough. The exterior trim will be attached to the same sheathing in the future. Important! The order of further installation of the lining depends on the location of the slats: if the slats are fixed vertically, the lining must be fixed horizontally, and vice versa. |

|

| The best material for the interior lining of a bathhouse is lining. The choice of cladding material is at the discretion of the owner. Fixing the sheathing elements is traditionally done using screws/self-tapping screws. |

Video - Insulation of walls and ceilings from the inside

Now you know everything about how to properly insulate a bathhouse with your own hands using the most optimal thermal insulation materials. The information obtained will help you cope with the planned events yourself, eliminating the need to contact third-party specialists and saving significant money.

Good luck!

Video - Insulation of a bathhouse from the inside, diagram

There are many materials for insulating a bath; there is plenty to choose from. These are mineral wool, basalt, fiberglass and foil foam, as well as various wood sealants. They are equally suitable for any job and are used for both walls and ceilings of steam rooms. When choosing the best way to insulate a bathhouse, take note of a few tips:

- The packaging must contain information about the thermal conductivity coefficient and the maximum thickness of the material. If the thermal range is indicated instead of exact numbers, then it is better to abandon it.

- You also need to choose the right density of the material. High performance is not always a positive thing. Give preference to those with lower thermal conductivity.

- Class fire safety should be marked as “GO” or “G1”. The insulation should not be toxic so that when used in the steam room, volatile substances harmful to humans are not released.

An excellent option would be foil penoizol. It does not require additional vapor barrier, and installation is carried out with your own hands. short terms without specialized tools.

Insulation of external walls - “fur coat” for a bath

A wooden bathhouse is insulated with tow. All inter-crown connections are laid on it. A structure made from rounded logs does not require this, because during processing, special cuts are made in the logs and they fit tightly to each other.

Wall insulation with outside is carried out only in brick baths. This is done according to the principle of a ventilated facade. Used as a material for vapor and waterproofing plastic film, and as insulation - mineral wool.

How to insulate brick walls - work plan:

- First, a frame made of metal profile, the distance between the guides should be selected based on the size of the insulation so that there is no need to cut it.

- Mineral wool is placed between the frame elements.

- The insulation is covered with a vapor barrier film on top to protect the wool from condensation.

- The joints of the vapor barrier material are taped.

- The insulation through the vapor barrier is attached to the wall with special dowels, the cap of which has the shape of an umbrella.

- After this, the walls are sheathed with the chosen finishing material.

There is nothing complicated and all the work on insulating the walls of the bathhouse from the outside can be easily done with your own hands. Thanks to the introduction to the market modern materials such as foil pinotherm, you can do without additional water vapor barrier. It is laid on the wall and the entire structure is sewn up with finishing material.

Insulation of walls from the inside

Having dealt with the external work, you can move on to the next stage. How to insulate a bathhouse from the inside? For this, an old, tried and tested method is used - constructing a frame with a gasket thermal insulation material. The principle is similar to the installation of a ventilated facade during insulation of an external wall.

- First, a frame made of wooden blocks or metal elements is mounted along the entire perimeter of the load-bearing walls. The distance between the frame guides should be equal to the width of the insulation.

- Then insulation is laid into the finished structure, over which foil waterproofing must be laid overlapping. The joints are glued together with construction tape.

- The final stage will be the installation of wooden lining.

This method is labor-intensive, but proven over the years. It will not be difficult to insulate the walls of a bathhouse with your own hands, but for clarity, you can watch the video.

Floor insulation

Let's describe general principle. They are insulated with polystyrene foam, and the diagram looks like this:

- We level the base as much as possible and lay waterproofing material.

- We carefully place the insulation on a flat film, filling the voids with cut pieces if necessary.

- We place a reinforcing mesh on top of this “pie” and fill everything with concrete.

- After hardening, it is carried out finishing, laying tiles, etc.

Many may ask, why foam plastic? This is the most durable and rigid material of all roll or slab insulation. It can withstand significant mechanical loads without changing its characteristics in a humid environment. Numerous air bubbles are hidden in the thickness of the foam, providing low thermal conductivity. It will not rot or become moldy over time. Essentially this is universal material, it is also used to insulate bathhouse walls both outside and inside.

Ceiling

This is a necessary part because a lot of heat escapes through the roof. Some still use old-fashioned methods, filling the attic space with soil, straw or sawdust. Today there are more modern options, but the essence of the work has not changed. it is necessary from the outside, that is, from the attic.

You can use expanded clay, polystyrene foam or mineral wool. On the side of the steam room, if the chimney pipe comes out through the top, it is covered with asbestos sheet and coated with fire-retardant mastic. You need to lay foam or mineral wool no closer than 15–20 cm from the pipe. Expanded clay can be poured next to the pipe, since it is absolutely non-flammable material.

The sequence of insulating the ceiling with your own hands:

- First, we cover the entire surface with waterproofing material.

- We lay material between the joists. If it is polystyrene foam or mineral wool, cut it according to size, fill it with expanded clay and level it over the entire area.

- We lay another layer on top of the insulation vapor barrier film and we sew boards on top of the structure - if you need to make a floor in the attic or lay flooring for passage during maintenance of the attic space.

When considering the use of expanded clay, it is necessary to take into account that this material does not have very good thermal conductivity and for normal insulation a thick layer will be required. Think about whether the ceiling will hold up? The most the best options will be rolled or slab insulation.

Entrance door

With comprehensive insulation, you will need to think about this problem. Experts recommend making doors narrow and low. This will significantly reduce heat loss. Well, if you still need additional protection, then let's look at how to insulate the door to the bathhouse with your own hands. There are several methods, varying in complexity of execution.

The first is laying material into the inner cavity of the door. This option requires a two-layer frame structure. The method is labor-intensive and not everyone can do it. On initial stage you will have to assemble the door from two panels, with a heat insulator placed inside.

With the second method, you can fix the material on top of the structure. Then cover everything with a decorative covering. This option is simpler. Foil insulation is stuffed onto the canvas, which is hidden under moisture-resistant plywood or other decorative material.

All measures to insulate the bathhouse inside and outside are carried out during the construction stage. An integrated approach and right choice materials will reduce the cost of heating the steam room and maintain a comfortable room temperature.

External or internal insulation baths are a must. This reduces fuel consumption and slows down the cooling process of indoor air. If the structure is not insulated, then it will take several times longer to heat the steam room to the desired temperature.

We insulate the bathhouse with our own hands

Before constructing a building, it is necessary to calculate the means and forces for thermal insulation. It is best if the insulation process begins during construction, more precisely, from laying the foundation.

Basic requirements for materials for bath insulation

Cheap solutions (impregnations, septic tanks) will not fulfill the role of good thermal insulation. Of course, protection from moisture is necessary in any case, but this is a separate task. It is necessary to insulate the bathhouse premises separately, using materials specially created for this purpose. Most attention is usually paid to the inside of the washroom and steam room. The selection of insulation and thermal insulation is done taking into account the rough construction material.

One of the most important requirements for insulation materials is non-toxicity. Because in a bathhouse under the influence of temperatures, toxic materials can easily cause poisoning. Non-hygroscopicity is also important; insulation should under no circumstances absorb moisture.

http://kakpravilnosdelat.ru/kak-uteplit-banyu/

When choosing a specific material, you need to rely on the following characteristics:

- resistance to steam and high temperatures;

- good fire-fighting properties;

- environmental friendliness;

- low hygroscopicity;

- ability to maintain shape for a long period.

Types of insulation for baths

All insulation materials presented on the construction markets are divided into three conditional groups:

Of course, 50–60 years ago they used only natural materials that were brought from nearby forests. This is foam, tow or moss. Today these are already partly elite types of insulation; they cost serious money due to the need to collect them manually. Many fans of natural materials insulate their buildings with rolled jute felt or tow. This material can be purchased at construction stores. When it comes to moss, there are conflicting opinions regarding its use. They say that moss is not an ideal material for insulation because it encourages the growth of mold or fungi. However, the moss itself does not have such properties; most likely, the fungus is formed due to improper cutting wooden structure or poor ventilation.

How to work with different types of buildings

The installation procedure and the required amount of work depend on the material from which the bathhouse is built.

Insulation of log houses

When working with timber or logs, you need to take into account the drying time, which can be 10 cm or more. Plus, cracks form between the crowns of such buildings, and cold air blows into them. It is best to insulate a log house made of round timber or an assembly of timber with jute fiber.

This material does not rot and has excellent thermal conductivity. Jute itself is a very fragile material, so manufacturers try to add flax fibers to it. But if you already have crumbly material, you can perform classic caulking. It will be so less work, and the building will probably retain more heat.

If you decide to create a bathhouse from wood, then the insulation is laid during construction. It is better to isolate all problematic parts of the log house in the process.

The work is performed in the following sequence:

Insulation of buildings made of brick or foam blocks

If log houses are insulated using a primitive method, then you will have to work hard with the masonry. Yes and financial investments more specifically for working with insulation. Additional thermal insulation is necessary, otherwise a well-heated room will cool down within hours. It’s better to work and invest in materials than to stock up on fuel the rest of the time.

A common and proven method is a suspended ventilated façade. The work process does not take place from the inside, but from the outside of the bathhouse. It is necessary to attach layers of insulation to the walls, and cover the top with siding or clapboard. In the gap between the layers, a space is formed filled with air, thanks to which condensation will not form on the walls and rotting and dampness will not follow.

The width of the frame for the ventilated facade is made larger than the thickness of the insulation, so an air gap is formed inside, preventing the formation of condensation

For a brick building, the following trick is often practiced: a steam room is made of wood inside the room. Brick absorbs heat for a very long time, so small room It’s easier to warm a steam room naturally if you use a small frame.

A 10x10 beam and sheathing are enough. The process of insulating such an improvised steam room inside a large bathhouse is simple:

You can make it even simpler: do not use timber, but instead immediately attach the insulation to the frame. In this case, an additional layer of waterproofing will be required.

Calculation and selection of materials and tools

We insulate all surfaces of the steam room, wash room and dressing room. And for this you will need:

- Roll paper (for ceiling and walls).

- Beam-rail (5x5, for installing insulation on the ceiling and walls).

- Foil.

- Insulating tape.

- Self-tapping screws.

- Aluminum adhesive tape.

- Insulation calculated according to the area of walls, ceilings and floors.

Tools you will need:

- screwdriver;

- level and plumb.

Do-it-yourself insulation of a bathhouse

Any stages of insulation are always carried out according to the golden rule - start from the ceiling and end with the floors.

Ceiling insulation

Before starting work with the ceiling, you need to understand that in the steam room you need 2 times more material. After all, we are not working on a sauna, but on a Russian bathhouse, where the steam should linger as long as possible.

The technology is like this:

- We cover the entire surface of the ceiling with overlapping roll paper.

- We fix the bars on top of the paper, the insulation will already lie between them.

- Cover it all with foil. It will become a normal, safe insulator. But it is necessary to install foil without saving. It is important that all connections are closed.

The foil layer reflects heat, so the use of such material for a bath is necessary

- We seal all joints on the foil with aluminum tape. Typically, foil for insulation is included with the material.

- We secure the edges and joints with several layers of adhesive tape. We check our work for leaks. If there is not enough money for such insulation, then the foil is sometimes replaced with cardboard or thick paper without paint.

- Next, we install layers of insulation on the foil between the closed bars.

On the ceiling, it is better to lay insulation in two or three layers, overlapping the joints

- We cover the front part of the ceiling with wood paneling. This material is resistant to elevated temperatures and will not resin.

For frame bath It is necessary to put insulation on the ceiling and walls, but for timber and log buildings you can do without it. For example, if a bathhouse is made of logs, it is enough to first sew up its ceiling with thick boards - at least 6 cm. Mineral wool is most suitable as insulation for the ceiling - you just need to lay it in a layer of at least 15 cm.

Video: insulation and finishing of the ceiling from the inside

Wall insulation

The best solution for wall insulation is a constructor made from materials that can be easily repaired or replaced.

The structure of the bathhouse wall insulation resembles the structure of a roofing pie

Video: insulation and foil upholstery of a steam room

Bathroom floor insulation

And finally, let's work on the floor. After all, a large amount of heated air usually leaves the room through it. Expanded clay is most often used as insulation for floors - it is an inexpensive and reliable insulation that prevents the formation of mold and condensation.

It’s cheaper, of course, to spill everything with slag, but expanded clay is more environmentally friendly and weighs less. When installing wooden floors, the material is placed between the joists. If a concrete floor is poured, then expanded clay is laid between each concrete layer.

Let's look at the usual cycle of work on insulating a concrete floor.

Video: features of installing a concrete floor in a bathhouse

In addition to walls, floors and ceilings, they also pay attention to the insulation of doors, windows and window openings. They are treated with silicone sealants. External doors are usually insulated natural materials. And it’s not customary to save on them, otherwise in a few years, or even next season, you’ll have to redo everything.