More and more often lately one can find references to such building materials as foam concrete blocks. Such blocks are used to construct the walls of garages, bathhouses, country houses up to two floors, decorate the outside of different buildings. This popularity is due to the presence of certain characteristics that positively distinguish this material from others similar to it: good performance sound insulation and thermal insulation, low weight of foam blocks and low cost. Today it is almost impossible to find a building material that would be absolutely perfect in everything.

So do foam blocks negative aspects, which for some may be decisive not in favor of choosing this material.

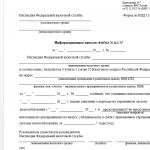

Scheme of vapor barrier and thermal insulation of foam blocks: 1. vapor barrier - polyethylene film;

2. internal foam blocks;

3. thermal insulation;

4. flexible fiberglass or metal connections;

5. facing brick from the street side.

Technological disadvantages

The main disadvantages of foam concrete include increased water absorption and reduced density.

So, let's look at the specific disadvantages of foam concrete related to the characteristics of the material itself:

- The need for protection from moisture. Any foam concrete block absorbs moisture, and in large quantities (up to 14% of the volume). Due to moisture saturation of foam blocks, such an important indicator as thermal insulation deteriorates. To protect against moisture, a waterproofing layer is required between the foundation and the blocks (to be fair, it should be said that waterproofing between the foundation and the wall plane is required for the vast majority of modern structures, regardless of the material used for the walls).

- Inability to pass air. Buildings made of foam blocks “do not breathe,” which means that they cannot support natural ventilation through the walls. Air renewal can occur exclusively through cracks, open windows and doors. Most often, this is not enough for normal human life, so additional ventilation systems are installed.

- Insufficient rigidity and density of the material. It is precisely because of this drawback that foam blocks are very rarely used in multi-story buildings; most often in such houses they are needed only to fill the voids between the floors. When building a wall, it makes sense to use the technology of reinforced concrete belts to add rigidity to the structure. If it is not possible to use such belts, then laying between the rows of reinforcement blocks is necessary. For greater strength, reinforcement can be laid in each row. Moreover, based on the realities of construction, even such measures may turn out to be insufficient. In particular for country houses the construction of a high-quality, massive foundation, tile or strip type, is required, despite the relatively low weight of the blocks. The cost of such a foundation is quite high, therefore, when planning, it is necessary to include all additional costs in the construction estimate.

- Variation in foam block sizes. Looking completely identical at first glance, foam concrete blocks have a variation in geometric dimensions of up to three centimeters on one side. This mainly concerns foam blocks, which are produced using artisanal methods, due to poorly made molds for the blocks. Geometric dimensions significantly affect the thickness of the seam between the foam blocks, and the heat-insulating properties already depend on the thickness.

Operational deficiencies

Foam concrete has the lowest compressive strength, but it is superior to brick in frost resistance.

Operational deficiencies are associated with problems that arise after the construction of foam concrete structures. Some of them have great value, for example, the need for constant heating, and some are just inconveniences.

- Some difficulties in the subsequent finishing of the wall. This drawback is closely related to the previous one. If you finish foam concrete blocks using cement-sand plaster, then in the future there is a very high probability of cracks appearing. Due to high moisture absorption, cracks also often appear on gypsum plaster. To avoid this, use a special reinforcing mesh or deep primers, with the possibility of multiple overlay.

- Loss of compressive strength over time. Any building material has a number of characteristics, one of the most important is compressive strength. Since a considerable mass is constantly pressing on the blocks (upper blocks, mortar, floors, roof, residents themselves), cracks may appear on them. Moreover, not only low-quality blocks are subject to this process, but also those that are manufactured in compliance with all standards. The appearance of cracks is observed in approximately a quarter of all laid foam concrete blocks.

- Difficulties with fastening. To attach something heavier than a small picture to a wall made of foam concrete blocks, you have to resort to some tricks. Fragile and crumbling foam concrete blocks are simply physically unable to hold massive objects for a long time. Manufacturers of foam concrete blocks suggest using special anchors, special screws, polyurethane foam. All the tricks taken do not provide one hundred percent strength. Most often, to achieve an ideal result, you have to abandon the placement of fasteners on the walls and use fastenings to the floor or ceiling.

- Buildings constructed from foam blocks require constant heating. If the owner of the house will be absent for a long time (throughout the winter, for example), then upon arrival he may notice that the house requires repairs, since the walls will most likely freeze, and excessive dampness in the house can cause rotting processes wooden elements buildings.

When planning the construction of a private house, it is logical to weigh all the pros and cons, compare and contrast different options and construction technologies, as well as the use of building materials.

Among many organizational issues, you need to decide what is best to build a house from.

The topic is broad and multifaceted, each material has advantages and disadvantages, but specifically in in this case wall material from cellular concrete– foam concrete.

Pros and cons of foam block houses

Pros of a foam block house

Low thermal conductivity

Cellular concrete materials (foam concrete, aerated concrete) have a unique porous structure, making them good heat insulators.

Light weight

Depending on what brand of foam concrete blocks are used, the weight is 1 cubic meter. ranges from 300 to 1200 kg. This leads to more lenient requirements for the foundation and, in practice, results in the opportunity to save on materials for the foundation of a foam block house.

Minimum hygroscopicity

In the process of producing foam concrete, a method is used to form blocks by pouring them into molds. This affects the geometry of the block, but promotes the formation of closed pores. It is thanks to this that foam concrete does not absorb moisture from environment. A simple test, immersing foam concrete in a container of water, can demonstrate the block's resistance to water absorption.

Durability of foam concrete

This is due to the fact that concrete, which forms the basis of foam concrete, gains strength during operation. That is, the longer the house stands, the stronger the foam concrete will be.

Resistance of foam concrete to fire

By class fire safety foam concrete is one of the safest building materials because it does not burn and does not support combustion.

Environmental friendliness of foam concrete

To make foam blocks, water, sand, cement and foaming agents are used. The latter can be of two types: natural and synthetic. Even if synthetic foaming agents are used, their specific gravity is no more than 0.5% of the total mass, which allows us to confidently declare the environmental friendliness of the material.

High speed of construction of a house from foam blocks

Installing one block is faster than laying bricks of the same square footage. Plus, the installation error will be significantly lower.

The ability to implement any architectural style

Foam concrete is easy to process. Cutting, drilling, and grinding the block is not difficult and does not require the use of special tools. Thanks to this, even a beginner with no experience in construction can remove the box of a foam block house.

Convenience of laying communications in foam concrete

Dictated by the flexibility of the blocks for processing, they are easy to groove for laying pipes, wiring, etc.

No finishing requirements

A house made of foam concrete can be used for a long time without additional finishing. As a rule, cladding is performed purely for aesthetic reasons. The most popular option is decorative plaster. Foam concrete house can be finished with any of the existing materials, it is important that they are designed for foam concrete blocks and do not affect negative influence on the microclimate in the building. Otherwise, the house’s ability to “breathe,” which is due to its porous structure, may deteriorate.

Easy to decorate

Thanks to the smooth surface or finish with any other finishing material With with minimal effort in preparation for finishing.

Relatively low price of foam block

Despite the fact that in absolute terms, foam concrete (35-39 rubles/piece) costs more than brick (6-10 rubles/piece). But to cover the same area, you will need one foam block (35-39 rubles/piece) and 13.5 bricks (13*6=78 rubles). The benefit is obvious. And taking into account the fact that the house does not need insulation and a strong foundation, savings can reach up to 30%.

Low cost of laying foam blocks

This aspect is relevant for those who do not plan.

Disadvantages of a foam block house

House shrinkage

A house made of foam concrete shrinks by 2-3 mm per linear meter; finishing can only begin after a certain period of time (at least six months). Shrinkage is caused by a long-term reaction between the constituent components of the foam concrete solution.

Foam concrete has a porous structure

The advantage of porosity is that it gives the foam block low thermal conductivity, but complicates the process of installing fasteners into the wall. The solution is to use special fasteners designed for foam concrete. Their price is practically no different from the cost of conventional fasteners.

Requirements for finishing material

For wall decoration they are used only special plasters and paints.

The need for foam concrete reinforcement

The reinforcement is laid in the area of the openings, and every 4-5 row of blocks is also reinforced. Without the appropriate reinforced belt, it is not possible to reliably install the floors and rafter system.

There is a high probability of purchasing a counterfeit

The fact is that the raw materials and equipment for the production of foam concrete are relatively cheap, so blocks are often made in an artisanal way, which is fraught with violations in production technology and affects the quality of the product.

Direct relationship between the strength/thermal insulation properties of a material

With increasing strength (structural grades D 1000-1200), the thermal conductivity of the material increases. Conversely, insulating foam block (grade D 300-500) cannot be used as a construction material load-bearing walls. Especially when it comes to multi-story construction.

The fragility of the foam block

On the one hand, it provides simple processing block, on the other it decreases bearing capacity material.

Requirements for calculating the load on foam concrete

The need for careful calculations of the thickness of walls and partitions, taking into account all possible loads. Usually walls are built with a safety margin.

Unaesthetic appearance of a foam block house

A house built from cellular concrete is often finished precisely in order to eliminate this drawback.

The need for a form-building foundation

Those. such a foundation for a house made of foam concrete blocks, which will help level out the low flexural strength characteristic of foam concrete.

Not ideal foam block geometry

This means that each block needs to be sanded before laying, which slightly increases construction time.

As you can see, a house made of foam concrete has both pros and cons. Therefore, it is difficult to give an unambiguous answer as to what characteristics a house built from cellular concrete blocks will have. It all depends on the quality of the material itself, the skill of the mason, and compliance. The master must mix negative aspects houses made of foam blocks to a minimum and not to ruin the benefits that the use of foam concrete imparts to the house.

House made of foam blocks - reviews from owners

Manufacturers of foam concrete and craftsmen who lay blocks unanimously claim that foam concrete is an ideal solution for individual construction. Foam blocks, large and at the same time light, allow you to build a wall in a record short term, and the porous structure makes it unnecessary to insulate a house made of foam concrete.

Is this really so or are the manufacturers hiding something from us?

You can impartially judge which foam concrete house is based on the reviews of those who already live in it. The opinions of real users differ, some think foam concrete ideal solution, others are categorically against it.

When deciding whether to build a house from foam blocks, reviews from the owners will come in handy.

Victor (Moscow region)

I offer my know-how. Maybe someone knows this trick, but I figured it out myself. I was going to build a house with my own hands. I have some experience and assistants too. I read a lot of reviews about foam concrete. They write in different ways. But, in the village, half of the houses are foam concrete. So I settled on it.

One thing that confused me was that if the screws don’t stay in the block, how to install the doors and windows? They fall out.

The decision came unexpectedly. The blocks intended for laying the outer wall were sawn worse than the blocks of the inner row, due to their greater density. So we decided to install denser blocks along the contour. So what if their thermal conductivity is lower, there will still be plaster inside. Everything is holding up great. And in order to actually hang shelves, you have to keep a supply of special dowels.

As an experienced builder, I note that it is necessary to strengthen openings, even arched ones, in any house, with metal corners. For clarity, here are a few photos.

Stepan (Tula region)

Why did we decide to build a house from foam concrete?

- The savings became noticeable even at the stage of pouring the foundation.

- The blocks were produced near the site - they were delivered free of charge. We have suburban area in the village of Malaya Dubna (Orekhovo-Zuevsky district, Moscow region) nearby is the manufacturer Penoblok.Ru.

- The geometry of the foam blocks is decent. We used special glue. At first glance, they overpaid, but the seams are thin, beautiful, and tight.

- The walls grew “by leaps and bounds”; we did not expect such a speed.

- The windows were installed immediately upon completion of the work.

We were frightened by the shrinkage of the house, but either the metal corners did their job, or the foundation did not let us down, or the house settled evenly, but no cracks appeared. True, it doesn’t look very presentable, but we haven’t gotten to the exterior decoration yet. In general, after 4 years of operation, there are no complaints.

Saburov brothers

We built a house made of foam concrete in the Rostov region. Summer here is warm but rainy, so over time we are going to cover the house with plaster. For now, to prevent it from picking up moisture, they covered it with a water-repellent agent. I asked the construction company and they recommended Antipluviol S Mapei. Expensive, in Rostov we have 5,200 for 5 liters.

I bought Ceresit ST 13 (2,150 for 10 liters). The walls don't darken, which means they don't draw water. The cracks have not increased over the 7 years of residence. And those that exist are clearly caused by the shrinkage of the foundation; the house did not stand up properly; they were in a hurry to build walls. As I understand it, the foam block, despite being lightweight, requires a good foundation. It's a pity that it came late. But finishing will improve the situation.

Nikita (Samara)

Before construction began, I read about the porosity of the foam block and that the fasteners do not hold well. Everyone advises using special fasteners. I thought this problem wasn’t worth a damn. It turned out to be in vain. How did it come to this interior works- at least shoot yourself.

While the water heater was hung up, they came up with so many devices so that it would stay in the wall and not fall on its head. Special dowels do not hold the heavy structure. We ordered furniture for the kitchen without any hanging units at all, only pencil cases and base cabinets. And it seems like this, small things, fasteners. Both the foam blocks are from the manufacturer and the construction technology is followed, but they are not insured against fragility in the walls.

Mikhail (Leningrad region)

I have been living in a foam concrete house for almost 12 years. Like any material, foam concrete has its disadvantages. For example, here and there there are cracks in the block itself, and there are a couple of cracked seams. But they are not critical and are probably caused by the fact that they used a mesh with a wire diameter of 2 mm for reinforcement, but it was necessary to take reinforcement of at least 6-8 mm. At that time, I didn’t want to bother with scoring the block, now we’re paying the price. But the house is warm, compared to its neighbors who live in insulated brick houses, ours, even not plastered, just holds the heat perfectly.

By the way, the walls are built in two rows. The first is made from a load-bearing (I don’t know the correct name) foam block brand D 800, the second is made from thermal insulation D 400. And yes, the dowels hold in it perfectly, the main thing is to take it longer so that they can reach the second layer. In general, there are no complaints about the foam block house. The main thing is not to be lazy and study the technology both for those who build it themselves and for those who order the work (so that they can control it). And of course, follow it during the construction process.

Sergey Mikhailovich (Karelia)

What can you think, put your hand on the foam block and brick. Foam concrete is much warmer. A clear demonstration of savings on insulation. Certainly, the best option If there was a tree, there would still be a unique microclimate in the house. But a rounded log or timber is more expensive, and it is not so easy to build a log house with your own hands.

So, from the point of view of microclimate and insulation, foam concrete is an ideal option. And complaints about cracks - so you need to stick to the installation technology or hire normal craftsmen. Otherwise they save on everything and then complain. It’s not for nothing that they say “the joy of a low price lasts less than the disappointment of poor quality.”

A house is not an object on which you need to save. Better finish do it gradually, and the frame and foundation should be as required by the technology. And even better with a margin of safety.

Mikhail (Tula region)

I chose foam concrete to build a temporary shed at the dacha rather for reasons of economy. As a basis, a shallow strip foundation (the soil allows). The main purpose is to store garden tools, hide from the rain, and a place for a snack.

Now summer cottages are gradually settling in, so we are thinking about building capital house. Based on the fact that there are no complaints about the temporary structure: the foam concrete has not cracked during this time, no cracks have appeared in the masonry, I will use foam concrete.

Conclusion

As you can see, there is no clear opinion on whether a house made of foam concrete is good. But most users agree that purchasing high-quality blocks and following the technology of building a house are the key to its long-term operation.

Knowledge of the features of this popular material will allow you to build a house or erect partitions without hassle. Basic rules:

- Buy foam blocks from trusted manufacturers.

- Pay attention to the clarity of the lines. Correct geometry is the key to quick and high-quality masonry.

- If you found quality material With flat surface, buy special glue for foam blocks. To work with adhesive composition skill and high qualifications of builders are required. The minimum thickness of the seam and the absence of irregularities will allow you to create monolithic masonry.

- In the absence of sufficient experience construction work and average quality foam blocks, use a cement-sand mixture good quality from well-known manufacturers.

- Achieve a seam thickness of up to 3 mm. A thick layer of glue or cement-sand mixture reduces sound and thermal insulation properties foam concrete blocks.

Advantages of foam blocks

Remember! good performance characteristics will appear only when high quality foam blocks!

Advantages This type of lightweight concrete has a lot of:

- Acceptable cost of material.

- Relatively small weight of the block - about 24 kg. Total weight buildings and the load on the foundation will decrease.

- You can build a house from foam blocks home handyman, who does not have much experience in construction work.

- The porous structure of foam concrete and low thermal conductivity retain heat well inside the building. In areas with warm climate you can discard the layer additional thermal insulation subject to high-quality masonry.

- The size of foam blocks is larger than that of brick. The work is moving much faster.

- The material lends itself well to processing. No expensive tools required.

- Foam concrete is made from environmentally friendly components. A low percentage of impurities does not affect human health.

- The material helps maintain a pleasant indoor microclimate. Even in hot weather, such a house maintains a normal temperature.

- Excellent sound insulation of the building is easily achieved due to the porous structure.

- High fire resistance.

Disadvantages of foam block houses

The relative cheapness of the production process explains some disadvantages of foam concrete blocks:

- The geometry of the blocks is often far from ideal.

- Unevenness complicates the laying of walls; a thicker seam is required, which leads to the appearance of “cold bridges”.

- Insufficient strength. The blocks may be damaged during transportation.

- Changes in the structure of the material over time, the likelihood of shrinkage inside the block.

- Low bending strength.

- Unpresentable appearance buildings made of foam blocks. Additional finishing is required.

Features of building a house from foam blocks

Before construction starts:

Before construction starts:

- study the characteristics of the material;

- find out the advantages and disadvantages of houses made of foam blocks.

The structure will be strong and durable if the basic rules are followed.:

- houses up to three floors high are built from foam blocks;

- to avoid cracks, the foundation is made of monolithic slab. Suitable option– monolithic tape with a special recess;

- for the strength of the building, the walls are reinforced;

- cladding with decorative or ordinary bricks will improve the appearance and reduce heat loss. You will save on heating up to 20%;

- a ventilated façade will protect the walls from dampness and create a good microclimate inside the building.

Pay attention! When building a house from foam blocks additional material often a brick. It is used for laying in places that bear the main atmospheric load. The main part is built from foam blocks. Be sure to follow exterior finishing facade to protect the foam concrete from exposure to precipitation and temperature changes.

If you prefer high-quality foam blocks for construction, do not worry: more expensive building materials also have advantages and disadvantages. Foam concrete has many more advantages than disadvantages. Before purchasing specify how to choose the “right” foam block, and then a house built from foam concrete will be strong and reliable.

You can choose any building material to build a house. Environmental friendliness, durability, accessibility - these are the main parameters that people pay attention to when choosing building materials. Listed below are the pros and cons of a foam block house – modern material for construction.

Advantages of foam blocks

Foam concrete blocks are larger in size than bricks, and they are lightweight. They are easy and convenient to work with, they can be easily cut with a special hacksaw. Due to their porosity and flexibility, the blocks can be used to hide pipes and wiring. Foam blocks do not place a large load on the foundation. Houses up to 5 floors can be built from foam concrete.

One is equal in size to 15 regular bricks

A microclimate suitable for living is created in a house made of foam blocks. The block structure allows you to support optimal temperature indoors. Thanks to the voids in concrete, excellent sound insulation is achieved. Foam concrete is fire resistant.

Foam blocks are excellent thermal insulation material- it is much warmer than brick or concrete

Foam blocks are relatively inexpensive. Due to the large size, the consumption of glue or solution is less than with brickwork. This is an economical material.

Foreman's advice:

Houses made of foam blocks are environmentally friendly. For people who care about health, foam blocks are the right choice.

Pros of foam blocks:

- efficiency;

- ease of processing;

- convenient block dimensions;

- environmental friendliness;

- sound insulation;

- thermal insulation and minimization of cold bridges;

- structural strength;

- resistance to external influences.

Disadvantages of foam concrete

Foam concrete blocks have a cellular structure, which makes this material fragile. Due to soil movements and shrinkage of the building, cracks may appear in the foam concrete. Foam blocks absorb moisture, of course not in the same way as gas blocks, but still. If the block, like a sponge, has absorbed moisture, which freezes when cold weather sets in, it disrupts the structure of the concrete, which again causes cracks to form.

- fragility;

- construction only in the warm season;

- hygroscopicity.

To combat these shortcomings, it is necessary to build a house on slab or strip foundation with a T-, L- or L-shaped profile, resistant to soil movements and earthquakes. To reduce the influence of hygroscopicity, it is advisable to carry out construction in the dry season and be sure to external finishing walls

Foreman's advice:

It is possible to build houses from foam blocks only in the warm season, since the binding solution or special glue is not intended for low temperatures. You can purchase frost-resistant glue, but it can only be used down to -10 °C.

Another disadvantage is the fact that foam blocks have been used relatively recently, which means that it is not yet possible to talk about the durability of houses made of foam blocks.

Video: comparison of foam concrete, aerated concrete and polystyrene concrete

You can choose any building material to build a house. Environmental friendliness, durability, accessibility - these are the main parameters that people pay attention to when choosing building materials.

Listed below are the pros and cons of a house made of foam blocks - a modern material for construction. Foam concrete blocks are larger in size than bricks, and they are light in weight. They are easy and convenient to work with, they can be easily cut with a special hacksaw. Thanks to their porosity and pliability, pipes and wiring can be hidden in the blocks. Foam blocks do not place a large load on the foundation.

Houses of up to 5 floors can be built from foam concrete. One standard foam block is the size of 15 ordinary bricks. A house made of foam blocks creates a microclimate suitable for living. The structure of the blocks allows you to maintain optimal temperature in the room. Thanks to the voids in concrete, excellent sound insulation is achieved. Foam concrete is resistant to combustion. Foam blocks are an excellent thermal insulation material - it is much warmer than brick or concrete. Foam blocks are relatively inexpensive.

Due to the large size, the consumption of glue or mortar is less than with brickwork. This is an economical material. Foreman's advice: Houses made of foam blocks are environmentally friendly. For people who care about health, foam blocks are the right choice.

efficiency; ease of processing; light weight and low load on the foundation; convenient dimensions of the blocks; environmental friendliness; noise insulation; thermal insulation and minimization of cold bridges; structural strength; resistance to external influences. Foam concrete blocks have a cellular structure, which is why this material is fragile. Due to soil movements and shrinkage of the building, cracks may appear in the foam concrete. Foam blocks absorb moisture, of course not in the same way as gas blocks, but still. If the block, like a sponge, has absorbed moisture, which freezes when cold weather sets in, it disrupts the structure of the concrete, which again causes cracks to form.

fragility; construction only in the warm season; hygroscopicity. To combat these shortcomings, it is necessary to build a house on a slab or strip foundation with a T-, L- or L-shaped profile that is resistant to soil movements and earthquakes. To reduce the influence of hygroscopicity, it is advisable to carry out construction in the dry season and be sure to do the external finishing of the walls. Foreman's advice: You can build houses from foam blocks only in the warm season, since the binding solution or special glue is not intended for low temperatures. You can purchase frost-resistant glue, but it can only be used down to -10 °C. Another disadvantage is the fact that foam blocks have been used relatively recently, which means that it is not yet possible to talk about the durability of houses made of foam blocks.

The construction of each house begins with design, drawings, and selection of materials. The main issue is the choice of building material for the construction of the box. Everything must be calculated, the pros and cons must be weighed. You can use brick, concrete blocks, cinder blocks, foam concrete, aerated concrete, wood.

It all depends on desire and financial capabilities. Today foam concrete is very popular. This material is better known as insulation, but it is used for the construction of private houses, country houses, garages, sheds, outbuildings.

Pros and cons

The name foam concrete speaks for itself.

Its composition is quite simple - it is liquid concrete that has been foamed. When starting construction, you need to analyze and weigh the pros and cons. Let's start with the advantages:

Pros of this material start with its cost. For little money you get an environmentally friendly pure material, it perfectly absorbs and releases moisture.

According to this indicator, it is comparable to wooden houses. Houses made of foam concrete have excellent thermal insulation. Thanks to its design with small cracks, it traps heat inside and prevents it from escaping. The sound insulation of this material is much higher than that of brick. Which makes living more comfortable. It is possible to reduce the laying time.

It is necessary to note the weight of the material, comparing with other materials, foam concrete blocks are quite light, the shape is even. Thanks to its light weight and large size, construction progresses much faster. With a simple composition, it is resistant to any temperature changes. It is not subject to combustion. Having a smooth surface, it simplifies finishing work. Working with foam concrete will bring a lot of pleasure, it can be cut hand saw, using a milling machine, drill.

You can make any shape from this material. Easy to create different geometric shapes, for example: arches, bay windows. It is also easy to install gables under any roof.

Foam concrete houses need to be finished facing bricks.

Considering the advantages, it seems like an ideal material for building walls. Unfortunately, foam concrete also has disadvantages.

The first minus is decorative finishing after completion of wall laying. It is advisable not to plaster all the walls; it is necessary to finish the outer walls with facing bricks. Without strong protection, foam blocks can withstand up to 20 freeze-thaw cycles.

This building material is used for low-rise construction, because it has high creep. Low cottages are often built.

When purchasing foam blocks, it is necessary to control the quality of the material.

You can request a building material quality certificate. Or you can check the strength yourself: you need to drive a nail 100 mm deep into the block and then try to get it out with your bare hands; if you can’t get it out, then you can start construction. If you got it easily, foam blocks are better return back.

A house made of foam concrete may lose qualities such as thermal insulation and sound insulation if the thickness of the seams masonry mortar will exceed 3 mm. Despite the disadvantages of this material, it is a leader in sales among building materials.

Return to contents

Differences between foam concrete and aerated concrete

Both materials belong to the same class of cellular concrete, but they differ radically in composition, technical, and operational characteristics. The production of foam concrete is simple; foaming agents are added to the concrete, poured into molds, and left to harden naturally. Foam concrete can be made at the construction site.

Aerated concrete consists of sand, lime, cement, gypsum, water, and aluminum paste.

Pores are formed as a result of the reaction. Hardening occurs under the influence high temperature. After hardening, it is cut into blocks of the required thickness and width.

The production of aerated concrete is possible only at the factory.

In addition, almost all factories have automated production. Aerated concrete is produced in accordance with GOST, which can be confirmed by a quality certificate. Thanks to this production process, the possibility of purchasing a fake is reduced to zero.

The production of foam blocks does not require huge expenses, special technologies. Its production is possible almost at home. Therefore, the chances of purchasing poor quality material are high.

You can judge the strength by the production method. If aerated concrete is produced in a factory according to standards, then in the production of foam blocks, to reduce costs, cheap analogues of foaming agents are used, which can reduce the quality of the material. Therefore, the density of gas blocks is higher than that of foam blocks.

Thanks to the internal bubbles that do not touch, the level of thermal insulation, sound insulation, and frost resistance of foam concrete is much higher than that of aerated concrete blocks. Another advantage of foam blocks is moisture absorption. It can be used in areas with high humidity, when gas blocks need to be treated with a special, expensive, water-repellent impregnation.

Return to contents

Foam concrete is the best choice for construction

If you decide to build a cottage, garage or need a small extension - the most the best option there will be foam concrete blocks.

This is a simple, environmentally friendly material for building walls in any home. Design and drawings of houses made of foam blocks take much less time than those made of brick or wood. Many companies also offer finished projects from foam concrete.

Thanks to its low weight, large sizes construction will move much faster. In addition, it has a number of advantages: excellent thermal insulation, sound insulation, fire resistance, high-quality foam concrete will last for many years. You will be satisfied with the house made of foam concrete.

The construction of walls made of foam concrete reduces the load on the foundation. When combined with price plus quality, foam concrete is inferior to most building materials for wall construction.

For the construction of low-rise buildings, cellular concrete blocks are widely used. This material has earned a lot of positive reviews. If you choose foam blocks, you must know the pros and cons of this porous concrete. There are nuances that affect the construction of a house made of foam blocks.

Knowledge of the features of this popular material will allow you to build a house or erect partitions without hassle. Basic rules:

Buy foam blocks from trusted manufacturers. Pay attention to the clarity of the lines. Correct geometry is the key to quick and high-quality masonry.

If you find high-quality material with a smooth surface, buy special glue for foam blocks. Working with adhesive composition requires skill and highly qualified builders. The minimum thickness of the seam and the absence of irregularities will allow you to create monolithic masonry.

If you do not have sufficient experience in construction work and the quality of the foam blocks is average, use a good quality cement-sand mixture from well-known manufacturers. Achieve a seam thickness of up to 3 mm. A thick layer of glue or cement-sand mixture reduces the sound and heat insulation properties of foam concrete blocks.

Advantages of foam blocks

Remember! Good performance characteristics will only appear with high quality foam blocks!

There are many advantages of this type of lightweight concrete:

Acceptable cost of material.

Relatively small weight of the block - about 24 kg. The total weight of the building and the load on the foundation will decrease. A home craftsman who does not have much experience in construction work can build a house from foam blocks.

The porous structure of foam concrete and low thermal conductivity retain heat well inside the building. In areas with a warm climate, you can refuse a layer of additional thermal insulation, provided that the masonry is of high quality. The size of foam blocks is larger than that of brick.

The work is moving much faster. The material lends itself well to processing. No expensive tools required.

Foam concrete is made from environmentally friendly components. A low percentage of impurities does not affect human health. The material helps maintain a pleasant indoor microclimate.

Even in hot weather, such a house maintains a normal temperature. Excellent sound insulation of the building is easily achieved due to the porous structure. High fire resistance.

Disadvantages of foam block houses

The relative cheapness of the production process explains some of the disadvantages of foam concrete blocks:

The geometry of the blocks is often far from ideal. Unevenness complicates the laying of walls; a thicker seam is required, which leads to the appearance of “cold bridges”.

Insufficient strength. The blocks may be damaged during transportation. Changes in the structure of the material over time, the likelihood of shrinkage inside the block.

Low bending strength. Unpresentable appearance of a building made of foam blocks. Additional finishing is required.

Features of building a house from foam blocks

Before construction begins:

- study the characteristics of the material; find out the advantages and disadvantages of houses made of foam blocks.

The structure will be strong and durable if the basic rules are followed:

- houses up to three floors high are built from foam blocks; To avoid cracks, the foundation is made of a monolithic slab. A suitable option is a monolithic tape with a special recess; for the strength of the building, the walls are reinforced; cladding with decorative or ordinary bricks will improve the appearance and reduce heat loss. You will save on heating up to 20%; a ventilated façade will protect the walls from dampness and create a good microclimate inside the building.

Please note! When building a house from foam blocks, brick is often an additional material.

It is used for laying in places that bear the main atmospheric load. The main part is built from foam blocks. Be sure to carry out external finishing of the facade to protect the foam concrete from exposure to precipitation and temperature changes.

If you prefer high-quality foam blocks for construction, do not worry: more expensive building materials also have advantages and disadvantages. Foam concrete has many more advantages than disadvantages. Before purchasing, find out how to choose the “right” foam block, and then a house built from foam concrete will be strong and reliable.

Modern building materials significantly different from their predecessors. Constant improvement leads to the fact that they become lighter, their performance improves, both strength and resistance to various aggressors, while the nominal cost decreases. Many people strive to build a house from foam blocks, the pros and cons, which are widely disputed by both professional builders and people who own such housing.

What is a foam block

Foam blocks are a material that is gradually replacing cauldrons, bricks and other natural or artificial stones. Ideally smooth edges, low weight, as well as the ability to produce foam blocks yourself make this material attractive.

To produce foam blocks, foamed concrete mortar is used, which is poured into special collapsible molds.

To obtain a cellular structure, gypsum, lime and, in some cases, aluminum powder are added to the solution. After pouring the solution into the molds, they are left alone until completely hardened. If necessary, finished foam blocks are trimmed and given a perfectly even outline.

Quite often, foam block is confused with gas block, although they have completely different production technologies and are united only by the fact that they both belong to the group of cellular materials.