Before purchasing a cork floor, familiarize yourself with the pros and cons of this product, which I will provide in full here. And if positive reviews on numerous sites are full of variety, then there are practically no negative reviews to be found. And not to find them due to marketing manipulation of this popular product. After all, in order to sell it profitably, no one will highlight the disadvantages.

I will describe cork flooring in this article not only as a master, but also as a consumer. The fact is that I had a cork in one of the rooms for about 6 years until I replaced it with laminate, and for this reason.

We purchased interlocking cork flooring for the children's room. We were guided by my experience in styling, the natural warmth and softness of the material. In this regard, cork is truly an excellent material.

It so happened that while we were going on vacation, we were left to stay in a relative’s apartment. Upon arrival, we found several damaged boards. The relatives used a work stool without a plastic plug, which was left over after the renovation. We purchased additional packaging of the coating and replaced the damaged areas.

A few years after replacing the old sofa with a new one, we saw a frightening picture. No, of course, we had noticed up to this point that the legs of the sofa leave marks, but we didn’t attach much importance to it. Nevertheless, the main area of damage was covered.

The depressing appearance of the damaged cork finally convinced my wife that it was in vain to listen to me and lay a cork floor. The cork itself was not pressed through, but the coating was damaged by knocked down and crumpled veneer. You heard right, in cork the top layer is covered with veneer. I offered to fix the matter in a simple way: Replace the cork. As a result of re-flooring, I removed the damaged panels to the last rows under the place of the future sofa. And we got the floor like new. Here it is, plus a glueless locking connection.

Another 3 years passed, while my son was in the village and I had a few free days, we decided to replace the cork floor with laminate. An old problem resurfaced - dark marks were left on the floor from the furniture legs. During dismantling, I carefully examined all the boards for further possible use or sale through Avito. For this reason, I sorted the flooring and this is what I noticed after 6 years of use.

What happens to the cork after 6 years of use?

Bottom of cork floor

The bottom of the cover in the locking version consists of technical cork. Roughly speaking, a 2-3 mm cork backing is rolled onto a sheet of HDF board. In my case I laid Art Cork over the foam insulation. Although it could be laid on bare concrete.

I read somewhere that a cork backing, if laid on concrete without a film, will rot, turn into dust, and so on. Nothing of the kind. In one place under the heating radiator, where the caring mother-in-law was hanging clothes to dry, water penetrated. There was a gap between the slabs. The HDF board sheet turned black, but the cork only changed color. That is, it does not become moldy due to the natural substances it contains.

Lock connection,HDF board

The lock joint used on my cork flooring is very similar in shape to the Uniclic locks. This type of adhesion is used on the famous brand of laminate "Quick Step". Considering the fact that I had already rebuilt the floor covering, the locks were in good condition, suitable for further installation.

Interestingly, the fiberboard is green in color. Usually this tone means the moisture resistance of the material.

Top layer of cork parquet

The top layer consists of technical cork. The fact that we choose different textures in the store, the pattern is an applied thin veneer of cork. And sellers, out of ignorance or intentionally, do not inform buyers about this feature. And this detail leads to abrasion and damage to the entire cork during operation.

Yes, the cork itself restores its structure under compression to almost its original size. Just as salespeople in stores convince us. But thin finishing cladding, which imparts nobleness to the coating, is not capable of this. It is crushed and pressed through.

Cork covering - pros and cons, review

It's time to leave your review and highlight the pros and cons of cork flooring. Now you know the structure of the coating, what it is made of, and it has become easier to draw conclusions.

Here I will leave a few links on cork flooring for your reference.

Floor covering is almost the most important element interior decoration premises. It should be wear-resistant, beautiful, and easy to care for. It is desirable that it is pleasant to walk on and that your feet do not freeze. Meets all these qualities flooring from a cork. Until recently, cork flooring was a very expensive luxury. Not to say that it is so cheap now, but it is no longer so inaccessible.

Types of cork floor coverings

If we talk about the appearance, there is a cork floor with a traditional pattern in different colors. But not everyone likes this design, so collections have been developed that imitate wood, stone, sand, even lawn grass. The images are very realistic (photo printing), and they are applied directly to the cork layer - there is no intermediate layer, because this floor is a product made from natural ingredients. The top of the design is covered with a protective layer of polyurethane or polyurethane varnish. Here is a protective layer - not the most natural, but there are no alternatives to it - the wood is also covered with varnish or paint.

Pros and cons

Cork flooring has many advantages. They are “quiet”, elastic, resilient, absorb sounds well, and conduct heat poorly. This floor is pleasant to walk on in both winter and summer. It is easy to clean - it is almost not electrified, dust does not “stick”, the smooth surface is easy to clean. Some colors are so “non-staining” that debris is not visible. This is also a minus - the dropped small thing it takes a long time to search.

One of the important advantages is that cork flooring is warm and soft.

It has few disadvantages - softness and high price. Softness is bad because the coating “sinks” under weight - furniture, fallen heavy objects, heels. But this drawback is compensated for when it is covered with several layers of varnish. And so that it does not sag under the furniture, choose it with wide legs, and also glue felt on them. When rearranging, you should also be careful - place plastic covers under furniture legs. They distribute the load well.

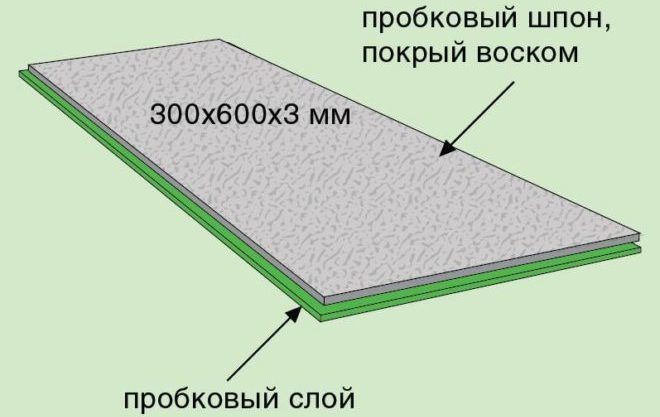

Structure

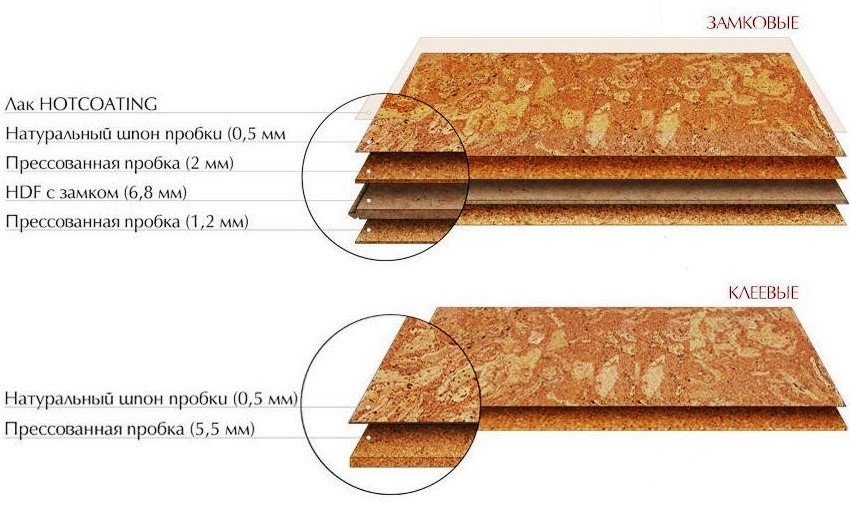

Both types of cork flooring - interlocking and adhesive - are multi-layered, but their composition is different. The adhesive plug usually consists (from bottom to top):

If we talk about thickness, then this coating is thinner. It's more flexible. This determines the requirements for preparing the base: manufacturers recommend having a completely flat base. Otherwise, any hole or hump will become visible over time. Practice has established that differences can be significant (up to 5 mm), but they must be smooth. There are no “steps” or cracks, but a smooth gradual increase or decrease is not visible. The difference in size that occurs during installation is compensated by the elasticity of the coating.

The interlocking cork floor also consists of several layers:

Interlocking cork flooring is more rigid and very similar to laminate flooring. But it’s only similar, since the laminate consists of pressed paper covered with a film with a printed pattern. The same material mainly consists of natural components. It is rigidity that determines manufacturers’ more lenient requirements for the base: there may be differences in height, but not more than 2 mm per 2 meters. You can also place a substrate under this coating, improving sound and heat insulation.

Lock or adhesive?

How to choose which cork flooring is better, interlocking or adhesive? Each is not bad, but has its own nuances. For ease of selection and clearer presentation, the properties of coatings are summarized in a table.

| Glue plug | Lock plug | |

|---|---|---|

| Reaction to humidity | Not afraid of high humidity and “flood” | May swell when exposed to water |

| Base | It must be perfectly smooth (according to the manufacturers’ requirements, no differences at all) | Differences of no more than 2 mm per 2 meters are allowed |

| Laying | Requires care or skill | Easy to assemble |

| Laying speed | A long process - spread glue, wait until it dries, adjust the plug, cover with 2-3 layers of varnish | A floor of 10-15 square meters can be assembled in a day (without experience) |

| Maintainability | You can cut out the damaged fragment, replace it and varnish it | You can replace a damaged plank, but you need to disassemble the covering from the wall to the place of damage |

From this we can conclude that it makes sense to install adhesive cork flooring in rooms with high humidity (kitchen, bathroom) and high traffic (corridor, hallway). You can even put it in unheated premises or where there are high differences in humidity and temperature (in bathhouses, for example). Interlocking cork flooring feels great in living rooms. The ease of installation speaks in its favor, but it is worth remembering that it is made on the basis of MDF and if water penetrates the seams, the base will swell and the plank will be deformed. After drying, unfortunately, it will not return to its previous form. But in this way it is no different from ordinary laminate, so this is not such a big drawback in living rooms. You just need to clean up spilled liquid in a timely manner.

Cork floor with photo printing - an option for an interior in style

This does not mean that adhesive coating cannot be used in rooms. It's very possible. Many people like it better, because with a good layer of varnish it has excellent strength - it is not pressed through by heels and furniture. Also the castle. It can be coated with a layer of varnish (but not from all brands) and used in the hallway, kitchen or bathroom. They also cover it with special oil with hard wax(OSMO type). The coating no less reliably protects against moisture penetration, but is easier to apply and can only be renewed in some places. The downside is the high price, but its consumption on the locking plug is minimal - it is absorbed only into the joints.

Species and subspecies

Please note that there are adhesive cork flooring available in different thicknesses. The thinnest tile is 4 mm, it can be laid in rooms with low traffic, but it is better to use at least a 6 mm coating. A special subtype is produced for the bathroom - large squares with a thickness of 10-12 mm and a size of 148 * 148 mm. A thinner covering of the bathtub leg will simply be pushed through.

In addition, an adhesive plug is produced with the first varnish layer already applied. It costs, of course, more, but the number of layers of varnish is reduced - even one layer may be enough. Also, the front surface of this type of floor finishing material is protected from dirt, and cork gets dirty very easily and all stains become visible after varnishing.

Modern cork coverings have not only natural colors. There are printed images of wood of different colors, sand with shells, grass...

There are also subtypes of castle cork flooring. First of all, it’s worth saying that there is a moisture-resistant version. The base of this material is not high-density MDF, but a special plate made of PVC and quartz, which is not afraid of water and high humidity. But this material is not like that large assortment colors and costs even more.

Any cork laminate has protective coating. But it can be made of two materials - varnish or transparent PVC. Varnish is more common, but PVC is stronger. Although, the laid coating with varnish top layer You can re-varnish it, achieving high moisture resistance, but whether this can be done with a PVC coating is a question.

It is also worth considering when choosing an adhesive cork floor that after applying varnish it appearance changes significantly. It becomes darker, the transitions are not so bright. To get a better idea of the end result, find an interlocking cover with the same color. Your end result will be about the same.

Manufacturers and quality of cork flooring

There are two large manufacturers of floor cork on the market: CorkStyle and Wicanders. They speak well of South Korean manufacturers. Their prices are not so high, and the quality is quite normal.

Specifically, during the selection process, pay attention to the cork conglomerate itself (pressed layer). To reduce costs, chips and other cheap material, but the quality of this product is already far from cork. It is tougher and wears out faster. Therefore, it is better to pay a little more, but choose one with a cork layer, even if it is pressed.

Those who are inclined to choose an adhesive plug for the floor should know that even very good producers the slats are imperfect. They differ in size - plus or minus 1 mm in width or length - these are normal tolerances. They are compensated by the elasticity of the material: when laying, the cork is slightly compressed so that the joints are tight. In addition, there are strips of different thicknesses. There is no way to compensate for this; you have to go through and sort them. Thin ones are laid in one place where the transition will not be noticeable; for thick ones, the excess along the edges is sanded off with sandpaper until the required thickness is achieved.

This is also a cork floor - for the nursery

In addition, there are defects on the front surface of the cork. It is lined with cork veneer, which is a natural material. It may have depressions, unsightly discolorations, etc. There may also be manufacturing errors - veneer peeled off in some places or the face veneer sanded down to the substrate. Before laying begins, all tiles are inspected, loose areas are glued back, and the remaining planks are used when laying in certain places. Read more about installation here, it also describes where to use these planks with flaws.

Cork laminate - interlocking cork flooring - does not have such problems - the protective coating has already hidden all the imperfections. But when choosing this material, pay attention to the reliability of the locks - in cheap materials they are the main problem.

Lightweight cork material is known to many as necessary for sealing expensive glass bottles of alcohol or making shoes. However, there is another wide area of application for cork - construction, or rather, finishing. Cork flooring is a relatively new finishing option. decorative finishing premises, and this option raises questions among many. In particular, it is believed that cork flooring is expensive, impractical and short-lived.

Today we will talk about the features, advantages and disadvantages of cork flooring, compare this unusual, if not exotic, building material with more familiar ones, for example, laminate or linoleum, and discuss the process of finishing the floor with cork sheets.

Cork is actually tree bark removed from the oak tree, which goes by a similar name, cork. Oak groves grow in the lands of the Mediterranean. In Portugal and Spain, multi-hectare plantations of this valuable oak are specially cultivated, and these states have long been recognized as world centers for the processing of raw cork, the production of finishing materials and related products from it. Note that oak plantations are also grown in Chinese territories, but cork oak needs a climate not only warm, but also with a certain level of humidity, and for this reason, Chinese cork is inferior to Portuguese and Spanish in quality.

When extracting cork, the tree is not cut down - the bark is simply removed from the trunks, leaving the oaks to continue to grow. From a tree that lives for more than one hundred and fifty years, the bark is removed regularly, every ten to twelve seasons. Therefore, the production of cork material does not harm nature, is environmentally friendly and humane in relation to trees.

To create panels from cork bark, the raw material is crushed into small pieces, poured into special molds and pressed in an oven under enormous air pressure and low temperature. It produces suberin - a unique, lightweight material, which is a mixture of cork crumble and air bubbles. Suberin plates are glued in two layers using natural resin, and they turn into monolithic, durable tiles.

What types of floor cork are there?

The cork industry supplies cork to the construction markets different types. Those that are suitable for floor use, include:

- Solid veneers. The most expensive cork material, consisting of a single, whole piece oak bark. Tiles are most often made from veneer different sizes, thickness and color shades.

- Agglomerates. Sheets made from crushed cork bark, which is glued into sheets or multi-meter rolls using tree resin. This kind of plug on the Russian market is the most budget-friendly, practical and widespread in construction stores.

- Combination of agglomerate and veneer. Small and large cork chips in combination with veneer are glued together under pressure, pressed into sheets or boards. The combined cork covering is made from veneer, which is not suitable for clean panels in size or quality, supplemented with crushed bark.

If we talk about a combined flooring made of cork or agglomerate, then a facing layer is usually applied to the front side of the finishing building material. It protects the floor from premature wear, and at the same time gives it decorativeness and aesthetics. The facing layers of cork flooring are divided into four types:

- Oak veneer protected with vinyl. The agglomerate covering on top can be covered with a thin layer of natural oak veneer, and then covered with a vinyl film, which does not distort the natural pattern of the bark, but protects the cork from sun rays, scratches or moisture.

- Veneer from other types of trees in combination with vinyl. The front layer looks and is made exactly the same as described in the previous paragraph, but it is no longer oak veneer that is used, but the bark of exotic or expensive wood species.

- Lacquer veneer. About half a centimeter of veneer is glued onto a base of pressed cork, which is then varnished in two or three layers to give the coating greater wear resistance, as well as a pleasant shine and decorative effect.

- Thin veneer. The cork chips are simply “covered” with a beautiful veneer covering to hide the chaotic pattern of the pressed bark.

Types of cork floors

The type of cork floor is selected depending on the finishing purposes, as well as the available time and financial resources. There are three options for cork flooring on the modern construction market.

Table 1. Three types of coating

| View | Description |

|---|---|

| Adhesive | Adhesive cork flooring is produced in the form of tiles of different sizes and thicknesses or rolls. Such tiles have a two-layer structure, with pressed cork chips on the bottom and decorative oak veneer on top, which is highly visually attractive. The adhesive floor tolerates moisture and temperature changes well, so it can be used in the balcony area, corridor, and kitchen. However, the adhesive plug requires a perfectly even coating, so preparation before finishing is extremely important. For installation of cork slabs, universal adhesives are used. |

| Castle | Lock-type cork floors are analogues of laminate. This coating is produced in the format of boards with fastening locks on the sides. Installation of an interlocking cork floor is carried out without an adhesive component or other fastening agents; all that is needed is a substrate, as for laminate. This type of coating consists of several layers, as a rule, the lowest, invisible layer is pressed natural chips of oak bark, in the middle - MDF board, giving strength, on top is a decorative layer of cork veneer or chips. |

| Technical | Technical coatings are made from cork remnants, so to speak, surplus production. This floor is not used for finishing, since it has no aesthetic value. Technical cork is produced in rolls or granules, and it is used to smooth out base defects, or to insulate and level floors before laying tiles, laminate, parquet, or linoleum. |

Prices for cork floors Wicanders

Wicanders cork floors

Cork as a flooring: pros and cons

Like anyone building material, a coating made from cork oak bark has disadvantages and advantages. Below we will talk about the pros and cons of cork so that you can evaluate this coating from the point of view of your own tasks and goals.

Benefits of cork

Firstly, the adhesive and locking coating is environmentally friendly and natural materials, which do not harm human health. Cork flooring can even be installed in the room of a small child or a family member who suffers from asthma or allergies. Let us note that not only the production of cork panels itself is environmentally friendly, but also the method of extracting cork - oak trees do not suffer in this process, since the trees are not cut down, but simply “stripped”, removing the mature bark.

In addition, the cork coating has an antistatic effect, that is, it prevents the accumulation of dust, mold spores and fungi do not grow in the cork, and when heated, the material does not release toxic harmful substances into the air and does not emit an odor. Cork is also an excellent insulator - it has a noise reduction effect and keeps the room warm well. It’s pleasant to walk on a cork floor barefoot, and the sound of footsteps will be muffled, and if any object falls on the surface lined with cork, there will never be a sharp and unpleasant rumble, just a dull thud

Natural cork flooring of any kind is slightly springy underfoot, which is useful for children just starting to learn to walk, as well as those who suffer from ailments of the musculoskeletal or joint system. Doctors admit that regularly walking in traffic jams reduces the load on joints and bones and forms correct foot placement. Another advantage of cork is that it does not slip, so a floor covered with this material will be an excellent solution in a house where there are children or elderly people.

The following group of advantages of cork covering can be classified as purely practical:

- Ease and efficiency of installation. The adhesive coating is simply pressed to the floor surface, having previously been lubricated with an adhesive composition, and the interlocking panels are laid like laminate - groove into groove. Special knowledge and skills, as well as expensive tools, are not required to lay cork on the floor.

- Practicality and unpretentiousness. Caring for cork flooring is simple - it is recommended to wash it with a damp (not wet) cloth, vacuum or brush, and sweep.

- Durability. If you do not spill solvents on the cork sheet or use abrasive cleaners, the coating will last at least ten years.

- No gaps, the ability to eliminate thresholds and baseboards. A cork floor can be monolithic, since the slabs are easily installed without gaps. Thus, the cork floor combines perfectly with other coverings, for example, tiles (you can immediately lay them closely), and if desired, there is also no indentation from the wall, which allows you to avoid using plinths.

A big plus of cork flooring is its versatility. You can use the cork both in the apartment and in country houses or at the dacha. The premises for laying cork can be any, the material is suitable for the kitchen or wet area of the bathroom, for the balcony or corridor, for the living room and any other residential area. Cork itself has low moisture resistance, but if you impregnate it with a wax-based product, it will last for many years even in high humidity conditions.

Disadvantages of cork

The advantages listed above are significant, but cork floors are not without their disadvantages. The first can be attributed to the high cost, and a glued floor will be almost twice as expensive as a castle floor. The second drawback is vulnerability to heavy objects, which include furniture. The cork will perfectly preserve the imprints of the legs of cabinets and sofas, and special spacers will only slightly smooth out the marks.

If we talk about adhesive floors, then only the installation process will be easy; dismantling the panels is extremely difficult, since strong adhesive is used to secure them. adhesive composition. Another disadvantage of an adhesive cork floor is that it is impossible to use it immediately after installation, since the panels are impregnated with a special varnish, and you need to wait until it dries.

Which floor is better: adhesive or interlocking?

When choosing a cork floor covering, each person faces a choice: to purchase adhesive panels or the so-called cork laminate, that is, interlocking panels. If we think from the point of view of ease of installation, especially if the installation is carried out by a non-specialist, then the interlocking coating will be more advantageous. This cork comes in different shapes, but they all have grooves on the sides, like laminate. Accordingly, installing such a floor is very simple - the boards or panels interlock with each other.

The interlocking floor has only two tangible advantages - ease of installation and, accordingly, dismantling, if necessary. There are more disadvantages: under the locking plug it is necessary to lay a backing made of foam material, and along the perimeter of the walls the coating must be covered with baseboards. In addition, a large number of joints imposes restrictions on the use of the floor, in particular on wet cleaning. The joints of the panels will absorb water and swell, so the interlocking coating must be coated with special wax, and the seams must be treated with a hydrophobic sealant.

In addition, like laminate, the locking plug must be selected according to the design, and in order for the final result to be aesthetic, the intended joint locations must be selected in advance. Accordingly, boards or panels will have to be sawn, selected according to length and ornament.

Adhesive cork coating has another drawback - you need to have experience to install it. To make the floor durable and beautiful, it is necessary not only to correctly apply the adhesive composition to the base and the cork itself, but also to adjust it to each other cork panels so that they appear as one whole, without the slightest gap.

The base on which the adhesive floor will be laid requires special attention. The base must be perfectly level, without bumps, drops or protrusions, and before installation, the floor must be washed several times to remove all debris. Limitations also arise after laying such panels - since glue plug covered with varnish, you must not step on the fresh floor, place furniture or any other objects on it until the varnish layer has dried. You won’t be able to use the room for a day or even more.

There are also several advantages to adhesive cork flooring. The first, and most important, is the high durability of the coating, its solidity and wear resistance. Also, the cork floor made from adhesive panels is absolutely natural, and fully conveys the beautiful wood pattern. The adhesive plug can be placed on the floor as a single piece, or you can combine two or more shades, and lay out the panels with different patterns.

Another important advantage is the ability to adjust the adhesive plug to any room by cutting out tiles of the desired size and shape, without any visible joints. High-quality installation of an adhesive cork floor allows you to do without the use of skirting boards, thresholds and other elements covering seams, joints and gaps. Simply put, the adhesive stopper is applied to the floor like wallpaper.

The glue plug has a small thickness, about five to six millimeters, so it does not hide the volume small room, but at the same time fully demonstrates its sound-proofing and heat-saving qualities.

How to choose a good cork floor?

When choosing a cork flooring material, you need to focus not only on its type: adhesive or locking, but also on the class of application. Like laminate, cork sheets are divided into three classes of wear resistance, and this is an important parameter that ensures the reliability and aesthetics of the future floor.

So, the cork presented in Russian construction stores comes in the following classes:

- 33 - recommended for installation in residential premises, as well as commercial rooms with average pedestrian activity (for example, in offices). Such floors for residential rooms have an average warranty of 25 years for the life of the cork, and for commercial floors - 15 years.

- 32 - recommended for apartments or houses with installation in rooms with constant active traffic (corridors, living rooms, kitchen area), as well as for offices or other commercial premises with low pedestrian activity. The guarantee for installation in residential rooms is 15 years, commercial - 5 years.

- 31 – the plug is intended only for living rooms where traffic activity is low (bedroom, nursery of a small child). The coverage guarantee is at least 10 years.

In addition to class, it is worth paying attention to the manufacturer's brand. It’s good if the cork fabric is made by a Portuguese or Spanish company. At the moment, the market leaders are such brands as Wicanders, Corkstyle, Allied Cork. Average price per square meter of cork flooring from these manufacturers varies between 1,600-2,700 rubles, respectively, more cheap options belong to class 31, those that are more expensive belong to classes 32 and 33.

How to lay cork on the floor: instructions

Regardless of what type of cork covering will be used, you must first prepare the base for it. There should be no serious unevenness or differences on the base (if the interlocking material is chosen), or a perfectly smooth screed should be used or the floor should be leveled with plywood slabs (under the adhesive plug). Once the base is ready, you can begin installation.

Laying the adhesive coating

Of course, by the time work begins, the room should already have the cork covering itself, as well as a special varnish to cover the cork after installation. To lay an adhesive-type cork covering on the floor yourself, you will need the following tools and accessories:

- A thin paint brush with coarse bristles for applying glue.

- Rubber hammer.

- Gloves to protect hands from adhesive mass.

- Construction knife for cutting tiles.

- Roulette.

- A roller with a long handle for varnishing the floor.

Step one

Laying the floor always begins five or six rows from the wall, the width of the row is always a multiple of the width of the cork tiles themselves. The material is laid with joints longitudinally to the light. Depending on the shape and size of the adhesive plug tiles, the design of the future floor should be selected. Typically, the cork is laid staggered, that is, its transverse joints never coincide, and the pattern according to which the tiles move is not guessed. You can lay cork tiles on the floor without glue, estimating how many of them will fit in a row, and also arranging them according to the shade or pattern. If the cork comes in a roll, you can skip this step.

Step two

Using a paint brush, glue is applied to the floor and tiles. You can apply a whole strip to the base at once, and you can also apply glue to four or five cork tiles at once, so you can lay them on the floor one after another without wasting time. The cork in a roll is glued in the manner of wallpaper - that is, both the base and the cork strip itself are smeared from beginning to end. Next, the adhesive mass should dry, follow the instructions indicated on the glue package. It usually takes from fifteen minutes to half an hour to dry.

Step three

Let's start laying the tiles. You can glue two rows at the same time. The first tile is placed according to the drawing, then next to it, on the side, the second tile is tightly glued, with an offset of two-thirds. This creates two rows that continue to the wall. Most likely, the last cork tile in the row that contacts the wall will have to be cut. This should be done during the process of laying the cork on the glue, and not in advance, in order to leave a minimum gap. The required size is measured with a tape measure and then cut with a sharp construction knife - it cuts the thin adhesive plug perfectly. In this way, the entire floor is laid out in the direction from the center of the room to the walls.

Rolled cork is easier to glue - the required length of the canvas is laid out on the floor, cut off from the roll, like wallpaper.

Table 2. What glue can I use?

| Name | Features, description | Approximate cost |

|---|---|---|

| Quelyd "Cork", France | One-component, self-drying composition. Has class environmental safety, can be used for heated floors. Setting time is about 25 minutes. | About 1,300 rubles per package of 3 kilograms |

| "Traffic" moment, Russia | Waterproof and resistant to negative temperatures, quickly and reliably glues cork to any surface (wood, concrete, iron, rubber, etc.). Setting time is about 20 minutes. | About 550 rubles per 1 liter package |

| Decol Vern, Portugal | Contact (instantly setting) adhesive composition that reliably and monolithically connects cork of any thickness to the base. The manufacturer does not recommend working with this glue without professional skills. Setting time: 15 minutes. | About 2,450 rubles per 5 liter package |

| Mapei Ultrabond Eco Contact, Italy | It is odorless, non-flowing (a type of thick paste), suitable for laying cork in rooms with high foot traffic. Has an environmental certificate. Setting time: 45 minutes. | About 2,300 rubles per package of 2.5 kilograms |

| Cipade Reviprene, Portugal | Contact, very strong adhesive composition, designed specifically for working with cork. Contains rubber components, intended for professional use. Setting time: 15 minutes. | About 2,300 rubles per 5 liter package |

Step four

When the floor is completely laid, it needs to be varnished. A special varnish, which can be purchased in the same department as the cork coating, is applied with a fleecy roller with long handle. You need to start applying the varnish layer from the far wall towards the exit, so that in the process you move back towards the doors, and not vice versa. There is no need to spare the varnish - the mixture should fill all the joints and possible unevenness of the canvas.

Important point! Before starting varnishing, you need to thoroughly mix the varnish, and then repeat the procedure every ten minutes to ensure an even coating. The joints near the wall need to be covered with a paint brush, because it is impossible to do this evenly and efficiently with a roller.

Cork varnish is a universal coating that not only gives visual effect, but also a protective floor material. The floor must be varnished immediately after installation, so you need to purchase the product in advance.

Table 3. What varnish can be used?

| Name | Features, description | Approximate cost |

|---|---|---|

| Lobadur 2K Supra Cork, Germany | Transparent matte varnish with low odor, suitable for use in heavily used areas. Moisture-resistant and frost-resistant. Consumption – 100 grams per square meter. | About 2,200 rubles per 1 liter package |

| BONA Traffic, Sweden | Two-component varnish water based, especially resistant to abrasion, adheres perfectly to cork without chipping during use. Consumption – 120 grams per square meter. | About 12,000 rubles per 5 liter package |

| BERGER Aqua-Seal 2K-PU, Germany | One of the most durable and strong varnishes on the market. It is environmentally friendly, dries quickly, does not have a strong odor, and has passed fire resistance tests. Consumption – 100 grams per square meter. | About 4,700 rubles per 1.6 liter package |

| LOBADUR WS EasyFinish, Germany | A water-based universal one-component varnish that additionally emphasizes the pattern of cork bark. Odorless, wear-resistant. Consumption – 100 grams per square meter. | About 15,000 rubles per package of 10 liters |

Video - Laying cork flooring with glue

Laying the interlocking covering

Before laying such a cork, the entire floor must be covered with a special foam underlay, exactly the same as what is placed under the laminate. In addition to the cork itself and the backing, you will need:

- Tape measures or ruler.

- An electric or hand file to cut off excess blade.

- Gloves that protect hands.

Step one

Installation of the lock plug starts from the wall. The first row of tiles or boards is laid along it, which are attached to each other by connecting the end grooves. If the floor is installed in a room with high humidity, the grooves are additionally coated with a special joint sealant before joining.

Step two

Next, the second row is laid - the cork is connected to the first row with side grooves. In this way, the entire canvas is laid out, right up to the next wall. Pay attention to the parts that will require trimming - it is better to place them in a less noticeable part of the room or where the furniture will be placed.

Step three

After the cork is laid on the floor, you need to screw the baseboards. Accordingly, there may be a gap of up to one centimeter between the wall and the outer tiles - this joint will be hidden by the skirting board.

Video - Installation of a lock-type plug

How to care for cork flooring?

Cork flooring is beautiful and practical, especially in terms of maintenance. But there are also rules and recommendations regarding the operation and maintenance of such coatings clean. Firstly, you need to monitor the humidity in the room so that the floor does not dry out. As we mentioned, cork oak trees grow in climates with high humidity, so in rooms where this indicator is below 50%, you need to use special air washers or humidifiers.

Caring for a cork floor is simple: material coated with varnish or impregnated with a wax composition can be wiped with a damp, but not wet, cloth, vacuumed, used household chemicals For wooden bases(no abrasive or solvent). However, if liquid is spilled on the floor from a cork, you need to immediately wipe up the puddle so that the area where the moisture gets does not swell. It is forbidden to use hard, iron sponges or aggressive brushes to care for the cork; there is no need to clean such a surface with scrapers.

Another important point caring for a cork involves periodically updating it. Since cork flooring begins to lose its aesthetics over the years, and the varnish becomes dull, it needs to be refinished. Using a sander or sandpaper, remove the remnants of the old varnish coating from the floor, carefully collect the dust with a broom and vacuum cleaner, wipe the cork clean and then varnish it again. In a day, the floor will dry and again sparkle with its unique texture and pattern of natural oak bark!

Summing up

Cork flooring, as is clear from the above, is an excellent option for any living space, with many advantages. If you are one of the people who values natural materials, ease of installation and ease of maintenance, then we recommend that you consider cork oak bark coating!

Various photos in manufacturers' catalogs and the Internet show that cork flooring is quite attractive in appearance and can look different, satisfying a wide variety of tastes.

What are the advantages of cork floors and are there any disadvantages? What do user reviews say? What types of cork floors are there?

How is installation done? This article is an attempt to answer the most common questions related to cork floors and help you make your choice.

Main features of cork flooring

Cork oak grows well in northwestern Europe and the northern part of the African continent.

This evergreen, capable of growing 20 meters in height and reaching a meter thick trunk. The plant blooms in May, and its fruits, like those of Russian oaks, are acorns.

The tree lives for about 250 years, and during this period, starting from the fourth decade, its bark can be removed every 9 to 12 years.

Cork is made from the bark of a plant. The largest cork oak plantations are in Portugal.

Approximately 360,000 tons of bark are harvested worldwide each year. In the 1930s, the USSR launched a project to plant cork oak groves in order to stop importing expensive imported cork into the country, but for some reason the cork industry did not gain much weight in a country that once occupied 1/6 of the landmass.

Most of the bark of the balsa tree is used to make wine corks. The wine industry has never been able to find a substance that can preserve bottled wine as well.

Cork stoppers affect the cost of wine, so they are used only for expensive brands. Cheap wines use other types of corks.

Flooring is the second-highest grossing product for southern oak bark products.

To make floor coverings, the bark is crushed and heated in special ovens. After this, the raw material is compressed under high pressure, and a semi-finished product is obtained - suberin. It is a mixture of cork and air particles.

To obtain finished floor coverings, a durable layer of wood dust and resins is applied to suberin, on which another layer of suberin is applied.

The front surface can be cork or other types of coatings can be applied to it, for example, polyvinyl chloride or veneer.

Cork floors perfectly insulate noise (dampen the sounds of footsteps and impacts on the floor) and help avoid heat loss.

Cork floors are credited with shock-absorbing properties - such a floor is quite soft, which reduces the load on the joints and spine. At the same time, as confirmed by reviews on forums, there are no dents left on the floor from the furniture.

Other reviews indicate that stiletto heels can leave indentations on cork floors.

Perhaps this depends not so much on the material as on the quality of the coating, but in any case, installing tiles in the corridor near the door may be more appropriate.

Almost all reviews on forums dedicated to cork floors note the amazing comfort of cork floors, which feel pleasant and not chilly on bare feet.

But like any other gender, cork has its downsides.

Adhesive and interlocking cork floors

There are two main types of cork floors - glued and interlocking. They are distinguished by installation and appearance, each of them has its own pros and cons.

Interlocking floors are plates of various shapes, mostly square or rectangular.

The locking system allows them to be installed like a mosaic without using glue - just like installing laminate or parquet boards.

The core of each plate consists of rigid MDF, which is inside covered with a 1.2 mm layer of cork compensating substrate, and on top with a 2.5 - 3 mm layer of front cork covering, decorated with cork veneer or photo printing.

Adhesive cork flooring is so called because of the need to install it with adhesive. This floor needs to be additionally varnished.

Adhesive coating is a professional one, since its installation is much more complex than laying interlocking cork floors, which can be done by anyone, even someone far from repairing.

Advantages of interlocking cork flooring:

- the plates are ready for use immediately after installation; installation does not require glue or varnish;

- can be laid on an imperfect floor - a difference in base height of 2 mm is allowed for every two meters of surface;

- floor installation can be done independently, without involving specialists;

- it is possible to dismantle and lay the plates in another room.

Disadvantages of a castle floor:

- can only be used in rooms with constant temperature and humidity;

- reviews show that if liquid gets into the joints, the floor may swell. The plates can withstand contact with liquid for no more than a day. During this time, it is necessary to notice the “leakage”, disassemble and dry the plates.

Advantages of adhesive coating:

- not afraid of contact with water, changes in temperature or air humidity;

- can be used in unheated buildings or rooms with high humidity;

- the ability to cut material facilitates installation;

- the coating can be tinted, creating mosaic-like floors, which opens up scope for design imagination;

- there is no need to install thresholds at the joints with areas of the floor covered with tiles or parquet.

Disadvantages of adhesive flooring:

- the base under the floor must be ideal, since even the smallest level differences will be noticeable on the finished floor;

- you need to purchase glue and varnish;

- guarantee high-quality installation Only qualified specialists can do this.

The cost of a castle floor is higher than an adhesive one, however, taking into account the purchase additional materials For installation and the cost of work, an adhesive floor will ultimately cost no less, and maybe even more than a castle floor.

Castle floors are suitable for bedrooms and living rooms in permanent residences.

Theoretically, children's rooms are included in this list, but children tend to spill liquids, so the choice of covering should be approached carefully.

It is better to choose adhesive coating for kitchens, bedrooms, country houses, in which the owners do not permanently reside, for office space.

More information about cork floors

Cork covering differs not only in installation or operational capabilities. Both interlocking and adhesive coatings provide a wide selection of colors and textures.

Some people like the distinctive look of cork, while others want something more interesting. Manufacturers of both provide a huge number of options.

Modern technologies allow cork flooring to imitate any type of wood from traditional (oak, pine, birch) to exotic ones such as rosewood, zebrawood, cocobolo, American walnut and others.

Today, one of the most fashionable methods of laying floors is the deck method, in which the boards are laid lengthwise, leaving a gap between them.

If you lay a cork floor using the deck method, you get a convincing solid wood effect.

Cork floors can reliably imitate the most different surfaces: stone slabs, sand, pebbles and so on.

Cork floors are an excellent solution for apartments with small children. Firstly, this floor is very warm.

This is due to the fact that, compared to tiles or laminate, cork absorbs heat from the human body much more slowly.

Cork is even warmer than parquet, which is considered one of the warmest natural flooring materials.

Secondly, neighbors below usually hear the patter of children's feet from the apartment above. Thus, cork flooring makes it possible to provide comfort inside and outside the apartment.

True, the opposite effect is not observed - if you are unlucky with noisy neighbors from below, then a cork floor will not help much, since it dampens the sounds of footsteps and impacts, but not sound waves traveling through the air.

Perhaps cork floors are not best choice for interiors with massive furniture, but for spacious and in every sense “light” modern interiors they fit perfectly.

Experts still advise using soft pads, such as felt pads, on furniture legs to protect the floor from damage.

According to reviews from users of various forums, the price of cork does not affect the number of dents.

For example, quite expensive Swiss coating (more expensive than Portuguese) is quite soft, so furniture legs with sharp tips or heels of stiletto heels can leave marks on them.

However, everything depends on the quality of the material, the professionalism of the installation, the uniformity of the initial floor covering, the quality of the final varnish coating, and the thickness of the cork layer also matters.

Typically, cork is used for small residential or office spaces, but there are unprecedented exceptions that demonstrate the potential of cork flooring.

Two thousand square meters of flooring in one of the main halls of the Sagrada Familia in Barcelona is made of cork.

This decision was made by the chief architect of the legendary structure, who assessed the acoustic and thermal insulation properties floor covering.

In addition, its appearance gives a luxurious impression. The thickness of the cork and a special finishing coating made it possible to achieve amazing performance properties - the floor can withstand thousands of visitors wearing different shoes every day.

Forum visitors never tire of arguing about the advantages and disadvantages of various floor coverings.

Universal the right choice does not exist, everyone will have to, after weighing the pros and cons, choose the most suitable option in a specific situation in a specific room.

Cork floors are becoming increasingly popular as a means of interior decoration. And if just recently cork was considered exotic, today this material confidently took the position of one of the most sought after. This is only beneficial for consumers, because now the choice is not limited to a dozen options - the number of textures and colors is in the hundreds. Meanwhile, not everyone knows what cork flooring is and why it is better than the usual linoleum or laminate. So, let's get acquainted!

How do you get a cork?

Cork is the bark of the cork oak tree, a native of the Mediterranean. The main suppliers are Portugal and Italy. Oak trees are specially grown and, upon reaching 25 years of age, the cork is removed for the first time. The bark is removed at the moment when the tree is ready to get rid of it, i.e. this procedure It is completely painless and harmless for the plant.

After 9 years, the oak restores its original thickness - the bark can be removed again. It is important to note that obtaining a cork is a manual process. Electric drills and saws cannot be used.

Benefits of cork flooring

If we talk about the advantages of cork, it is necessary to note the following:

- soundproofing. Are you tired of your neighbors complaining about your child running around your apartment? Cork floors will solve this problem, because they have no equal in their ability to “muffle sounds”;

- thermal insulation. The cork floor is always warm, you can walk on it barefoot without any problems, even in winter;

- immunity to deformation. No matter how heavy your furniture is, you don’t need to worry about dents on the floor - they simply won’t happen;

- excellent shock absorption. Impeccable shock-absorbing qualities have been confirmed by doctors. It has been proven that walking on a cork floor is beneficial for the body, because... the load on muscles and joints is significantly reduced.

It should also be mentioned that cork is of no interest to wood-boring insects and rodents.

Cork floors have earned the most positive reviews due to their unique design. The production technology consists of several stages: the bark is crushed, then heated and placed under a press. As a result, the granules, sticking together, form a closed cellular structure. The honeycomb-like base contains many bubbles impregnated with suberin, a natural cork substance. Each component of such a structure is a shock-absorbing spring, an acoustic absorber, and a reliable heat insulator.

Cork flooring is a multi-layer structure. Components:

- cork agglomerate (crushed cork);

- high strength board (resin-based wood dust);

- again cork agglomerate;

- front layer.

The front layer varies. It can be made of decorative veneer, or it can be made of valuable wood, coated with varnish or a layer of vinyl.

The middle layer of high-strength board is used only in floating cork floors; in adhesive floors, the middle consists of agglomerate.

Types of cork flooring

Cork floors come in two types: floating and adhesive. The first ones have the form of panels 9-12 mm thick. They are joined using grooves. On average, the service life is about 5 years. This indicator depends on the quality of the varnish with which the cork is coated. If the manufacturer prefers exclusively high-quality materials, then the “lifetime” of the final result increases.

Adhesive floors are tiles with a thickness of 3.2 mm, 4 mm and 6 mm, which are glued to the base. The most durable plug is 3.5 mm, suitable for industrial premises and offices.

Adhesive flooring is more expensive and more expensive to install simple matter you can't name it. But the reward for your efforts will be increased wear resistance: on average, an adhesive cork coating will last at least 7 years, and if you apply an additional layer of varnish, then even more.

This is important!

For an apartment, it is better to purchase a 6 mm adhesive floor, which will retain heat and easily provide the proper level of comfort.

Choosing a cork floor

How to choose a cork floor is not an idle question for those who value truly high-quality products. What should you consider first?

The main criterion when purchasing is the manufacturer. The most best companies: Wicanders, Allied Cork, Corkstyle (Portugal). Next is the appearance. The cork must be carefully packed, the edges must be free of burrs and irregularities. Take the time to check whether the samples are the same in size - to do this, simply attach two tiles to each other.

Turn the cork tile over. Have you noticed any foreign inclusions? This means that the manufacturer, having decided to save money, mixed cork with sawdust - the material will retain heat and absorb noise much worse.

For the living room and bedroom, purchase a locking plug; for the bathroom, kitchen and hallway, buy an adhesive plug. If it happens on your own, then pay attention to copies with a chamfer. Chamfer - a layer removed at a slight angle. Such a plug will masterfully hide installation unevenness, which is inevitable in the absence of experience or in the presence of significant differences in the base height.

Consider class affiliation. Class 31 cork is used mainly in rooms with low traffic (bedroom, children's room); 32 classes - in rooms with average traffic (living room, kitchen); 33 classes - where the load is greatest, for example, in the hallway.

Cork floors are a modern floor covering that has many advantages. So why not take advantage of such a valuable circumstance and fill your home with sunshine and warmth?