Linear thermal fire detectors. Installation and installation examples

FIRE DETECTORS THERMAL LINEAR INSTALLATION AND INSTALLATION EXAMPLES

The previous issue of the magazine “Safety Algorithm” (2013, No. 3) presented material about linear thermal fire detectors, their purpose and principles of operation.

In this article we will talk about the features of installing thermal linear sounders, their use in complex facilities, and present several standard solutions on their installation.

Let us remind you, just in case, what a linear heat fire detector or thermal cable is. This is a signal cable that responds to changes in the maximum temperature of any section along its entire length. The thermal cable is both a sensor and a cable. Any point on a linear heat fire detector can be considered as a separate heat sensor. The rules for installing a thermal cable are the same as for point heat fire detectors with normally open contacts.

INSTALLATION OF THERMAL LINEAR FIRE DETECTOR

All types of thermal cables are mounted using special fasteners. Terminal connectors and crimping devices are used to splice cable sections. The thermal cable is installed in continuous sections without bends or branches (like a snake). It can be placed on the ceiling of the protected room or structure or on the walls. In areas where installation is difficult, it is recommended to place the thermal cable on a steel carrier cable.

Before installing the thermal cable, you must carefully plan where it will be laid. Planning is carried out on the basis of drawings of protected or controlled areas, taking into account data on the location and configuration of cables in space. Incorrect installation or mounting of a linear heat detector can lead to its mechanical damage, for example, in technological areas, warehouses where loading equipment is used.

It is recommended to place the cable with the possibility of tension. In this case, the installed section of the detector must be unwound. At the same time, the other, unused part of the detector must be wound up. This will guarantee an easy and reliable installation. Installation of a thermal cable is recommended at temperatures from -10° C and above. While operation is possible even with extreme temperatures from -40° C to +125° C.

For security open spaces(awnings) it is recommended to install the thermal cable at a distance of 500 mm (20 inches) from the ceiling. The operation of the thermal cable can be improved by running down walls or racks (columns). Thermal cable installed in close proximity to danger zone, has the additional advantage of fast response.

At the same time, the detector itself should not interfere with routine maintenance in the protected area. On level ceilings, the distance between detector(s) lines should not exceed 10.6 m/35 ft (UL certified). According to International FM Standards, the distance should be 9.0m/30ft for TH68 and TH88 or 7.5m/25ft for TH105. The detector should be located at the listed distances from walls measured at right angles within 18 inches (460 mm) of the ceiling.

Also during installation, the so-called “dead zone” should be taken into account. In most cases, the “dead zone” is a triangle with sides 10-20 cm along the ceiling and 10-20 cm down the wall. It is not recommended to lay a thermal cable in this area, because this significantly reduces the protection of the object from fire.

If a linear thermal fire detector is used to trigger automatic fire extinguishing systems, additional requirements may be imposed on its installation in accordance with the specifics of the protected object.

FASTENING DEVICES

FASTENING DEVICES

For proper and trouble-free operation of the entire system, it is necessary to use only original fastening components recommended by the manufacturer. The use of non-original fasteners or improvised material can damage the thermal cable, which in turn leads to false alarms and malfunction of the entire system.

Each thermal cable manufacturer offers a wide range of fastening devices. Here are some illustrative examples of such devices:

GENERAL PURPOSE FASTENERS

The T-shaped fastener allows you to quickly and easily secure the thermal cable in the right place. The design of the fastener provides a specified distance between the thermal cable and the surface to which it is attached for heat removal. This fastener is convenient because there is no need to remove it when replacing or repairing a thermal cable (Fig. 1).

Figure 2 shows a fastener that uses a TwistLock type lock. The fasteners can be used to secure thermal cables in cable trays, warehouse racks, concrete walls or on roofs (Fig. 2).

The cable clamp is designed for fastening thermal cables in industrial and commercial buildings. The design of this fastener rigidly fixes the thermal cable, ensuring heat removal and preventing its vibration (Fig. 3).

Self-adhesive clip. Convenient for use at ambient temperatures from -40° C to +85° C. There is a hole for a screw. Using this fastener, you can easily disconnect and re-fasten the thermal cable (Fig. 4).

The cable clamp (Figure 5) is the most versatile type of fastener and can be used to mount the detector to the ceiling or wall, as well as in all corners. Resistant to ultraviolet radiation and withstands temperatures from -40° C to +85° C.

Holder for flat ties(Fig. 6), installation in a blind hole. This fastener is mainly used for fixing thermal cables on ceilings and walls made of concrete or brick.

The L-shaped bracket (Fig. 7) provides reliable fastening thermal cable. Using the holes in the bracket design, you can adjust the position of the thermal cable in height.

L-shaped bracket (Fig. 8). The metal bracket is intended for fastening the thermal cable on tanks for storing oil and petroleum products with a floating roof, as well as for fastening the thermal cable in places where it is necessary to fix the detector at a distance from a flat surface (wall, ceiling, etc.).

Flat tie holder (Fig. 9), secured with a screw. Its characteristics are similar to the L-shaped bracket. The thermal cable is fixed using cable ties. Designed for indoor use.

FASTENING FOR WAREHOUSE SHELVES AND CHANNELS

FASTENING FOR WAREHOUSE SHELVES AND CHANNELS

Figure 10 shows fasteners that are used to rigidly fix a thermal cable in various cases, including for attaching a thermal cable to a channel or storage shelf.

Figure 11 shows fasteners designed for securely attaching a thermal cable to warehouse shelves(metal corners), or to the channel. This fastener has the necessary air gap between the thermal cable and the surface to which it is attached.

Beam clamp (Fig. 12). Designed for attaching thermal cables to beam structures. Can be used in conjunction with a mounting clamp.

LONG DISTANCE FASTENERS

To fasten a thermal cable over large areas where it is not possible to fix it on any surface, you can use a structure consisting of a steel support cable (withstands a load of up to 90 kg), a bolt with a ring and a lanyard that provides the necessary tension of the support cable. It is recommended to attach the thermal cable to the cable every 3 m. The distance between the bolt with a ring and the lanyard, without intermediate fastening, should not exceed 75 m. In addition, it is recommended to install intermediate fasteners of the supporting cable every 15 m to avoid sagging of the thermal cable. The elements of this design are presented in Figure 13.

Rice. 17. An example of laying a thermal cable (indicated in red) in cable trays

Rice. 18. Example of laying a thermal cable to protect a conveyor

FASTENERS FOR PIPE AND CABLE TRAYS

FASTENERS FOR PIPE AND CABLE TRAYS

The double tie (Fig. 14) is intended for fastening the thermal cable to the pipes.

Clamp tie (Fig. 15). Universal cable tie. Used for attaching a thermal cable to a cable or to cable trays.

ELEMENTS FOR SPLICING THERMAL CABLE

The crimp sleeve (Fig. 16) is designed to connect two sections of the thermal cable. Special crimping tools are used for the job.

Terminal block for connecting thermal cable. Used in conjunction with insulating tape.

Rice. 19. Example of laying a thermal cable to protect a tank with a floating roof

EXAMPLES OF THERMAL CABLE INSTALLATION

High efficiency, easy installation and can be used with almost any system fire alarm/ a thermal cable is made into a fire extinguishing system universal remedy fire detection. Often, the use of conventional fire detectors is not feasible due to their specific features: the impossibility of installation at subzero temperatures and moisture, operation in the presence of dust and soot, installation in hard-to-reach places and in aggressive environments. Therefore, using a linear thermal fire detector is the most suitable solution to these problems. Currently, thermal cables are widely used to protect tunnels, car parks, wood processing plants, oil, chemical, cement and coal processing plants.

The peculiarity of the thermal cable is that it can be laid in close proximity to the equipment being protected, as well as in all parts of the building, including elevator shafts, garbage chutes, staircases and others hard to reach places In addition, the thermal cable can be used to protect escalators, transformer substations, electric motors, etc.

CABLE TRAYS:

To protect cable trays, it is recommended to lay a thermal cable in each tray, as well as under each tray, to protect against fire from debris or dust. For a tray with a width of 600 mm, it is recommended to lay one thermal cable, for a tray with a width of 900 mm - two.

An example of laying a thermal cable in cable trays (Fig. 17). When protecting cable trays, the thermal cable is laid on top of all power and control cables and has a sinusoidal configuration. When installing additional cables in the tray, they must be laid under the detector. For fastening, it is best to use double tie clamps or standard tie clamps.

rum, for this the detector must be secured parallel to the conveyor using a support cable, a lanyard and a bolt with a ring. The thermal cable itself is attached to the supporting cable using cable ties, or is wrapped around the cable. The distance between the bolt with the ring and the lanyard, i.e. controlled area should not exceed 75 m. In addition, in order to avoid sagging of the thermal cable, it is recommended to install intermediate fasteners ( anchor bolt with a ring) of the supporting cable every 15 m. It is recommended to attach the detector to the cable at least every 3 m.

Fuel and lubricants storage tanks with a floating roof:

To protect a tank with a floating roof, it is recommended to lay a thermal cable around the perimeter of the floating roof (Fig. 19).

POLLS STORAGE TANKS WITH A FIXED ROOF:

We give an example of laying a thermal cable to protect a tank with a fixed roof in Figure 20 (the thermal cable is indicated in red).

Rice. 20. Example of laying a thermal cable to protect a tank with a fixed roof (thermal cable marked in red)

ESCALATORS:

ESCALATORS:

We give an example of installing a thermal cable to protect an escalator in Figure 21.

Rice. 21. An example of installing a thermal cable to protect an escalator

PARKING:

PARKING:

We give an example of laying a thermal cable to protect a parking lot in Figure 22. To avoid sagging of the thermal cable when installing on flat ceilings, it is recommended to mount the detector at least every meter.

Rice. 22. Example of laying a thermal cable to protect a parking lot

TUNNELS:

TUNNELS:

Rice. 23. An example of installing a thermal cable to protect tunnels

WAREHOUSE RACKS:

WAREHOUSE RACKS:

To protect warehouse racks, a thermal cable is placed parallel to the rack sections above each level of the sprinkler system in a single cable using lead wires (Fig. 24).

Rice. 24. An example of laying a thermal cable to protect warehouse racks

In conclusion, let us note that when designing and installing linear thermal fire detectors on the territory of the Russian Federation, one should be guided by the requirements of NPB 88-2001 or SP 5.13130.2009 for linear thermal fire detectors and thermal fire detectors.

The editors thank the company Pozharnaya Avtomatika LLC for the materials provided

Linear heat detector (thermal cable) manufactured by Protectowire (USA)

Call for pricing!

Linear heat detector (thermal cable) produced by the company Protectowire(USA) is a cable that is designed to detect fires by an increase in the optical density of the environment when it is smoke-filled, by the value of the ambient temperature anywhere along its entire length. The thermal cable is a sensor continuous action and is used in cases where conditions do not allow the installation and use of thermal point detectors, and in conditions of increased explosion hazard, the use of a thermal cable is the optimal solution.

Main characteristics

Set response temperature throughout;

Issuing a "FIRE" signal based on six temperature values;

High resistance to humidity, dust, low temperatures and chemicals;

Indispensable in hazardous areas;

Easy to install and configure;

Economical, no operating costs;

If necessary, extensions are simply added to the system;

Does not require maintenance;

Expected service life more than 25 years;

Has a SSPB certificate.

Description

The Protectowire Linear Heat Detector consists of two steel conductors, each of which is insulated with a heat-sensitive polymer. Insulating-coated conductors are twisted to create mechanical stress between them, then coated with protective insulation and encased to protect them from impact. unfavorable conditions environment.

When a threshold temperature value is reached, under the influence of pressure from the conductors, the insulating coating made of a heat-sensitive polymer is destroyed, and the conductors short-circuit. This occurs at the first overheating point along the thermal cable route. The Protectowire thermal cable is a maximum heat detector and therefore allows an alarm to be generated when a temperature threshold is reached at any point along the entire length of the cable.

Classification of thermal cable

Currently, there are four types of thermal cable: EPC, EPR, XLT, TRI (TRI-Wire™) differing in purpose and material from which the outer protective sheath is made, for use in the most different conditions environment.

Type EPC

Thermal cable type EPC has a vinyl protective sheath, which gives the cable good flexibility at low ambient temperatures. The thermal cable is universal and well suited for both industrial and commercial use.

Type EPR

Thermal cable type EPR has a durable, fire-resistant outer sheath made of polypropylene that is resistant to ultraviolet radiation. Designed for wide industrial use in places with elevated ambient temperatures. It has high reliability, elasticity, resistance to abrasion and exposure to atmospheric factors.

PHSC-190-EPR

PHSC-280-EPR

PHSC-356-EPR

Type XLT

Thermal cable type XLT has a special outer sheath that is resistant to low temperatures. Specially designed for use at extremely low temperatures in warehouses, refrigerators, freezers, unheated warehouses, as well as in the harsh climatic conditions of the north.

TRI type (TRI-Wire™)

Thermal cable type TRI (TRI-Wire™) is a combined (two-temperature) heat detector that produces “ATTENTION” and “FIRE” signals based on the set temperature thresholds. The thermal cable has a durable, elastic, moisture- and fire-resistant vinyl outer sheath that is resistant to most common chemicals.

Technical data

|

designation |

Logics |

Temperature of actuation, o C |

Operating temperature range, o C |

Application area |

|

For one temperature |

Normal conditions |

|||

|

Aggressive environments |

||||

|

Low |

||||

|

Combined (for two temperatures) |

68-"Attention" |

Getting a double trigger |

Protectowire thermal cable installation method

The Protectowire thermal cable must be laid in solid sections without bends or branches in accordance with the requirements of fire inspection authorities for the location and configuration of the thermal cable in space. In addition to the requirements for dividing into detection zones (determination of the alarm source), the length of each piece of thermal cable is limited and controlled by the control device to which the detector is connected.

Standards for installing a thermal cable (linear heat detector) in accordance with NPB 88-2001*, clause 12.37

The Protectowire Linear Heat Detector operates on the principle of a normally open contact that closes when triggered. Therefore, the thermal cable should only be used in alarm loops that can detect a contact closure and transmit an alarm signal.

The Protectowire thermal cable is a contact device with active resistance distributed along the entire length of the cable, unlike traditional point heat detectors that change their resistance when triggered. The relatively high resistance of the detector, 1 Ohm for every 1.5 m of twisted pair, requires measurements of the resistance of each device to which the thermal cable will be connected, in order to determine the maximum allowable length of the thermal cable in order to avoid exceeding the established maximum resistance of the alarm loop.

When using large sections of thermal cable, the resistance in the loop may exceed the permissible values, as a result of which the control panel will constantly issue a “Fault” signal, or the alarm loop will not be able to generate an alarm. This problem is solved with the help of interface modules PIM-120, to which you can connect up to 2000 meters of thermal cable and PIM - 420D - 1525 meters of thermal cable.

The Protectowire linear heat detector responds to changes in ambient temperature when a fire occurs. Therefore, used installation materials must provide adequate support at temperatures not below the threshold. Fastening devices are installed every 1.5-3 m, and also if it is necessary to prevent excessive sagging of the wire, which causes tension on the wire at the fastening points. Incorrect installation or fastening of the thermal cable can lead to mechanical damage to the detector, for example, in technological areas, warehouses using loading equipment.

Thermal cable location.

The Protectowire linear heat detector must be installed in the protected area on the ceiling or on the walls at a distance of no more than 500 mm from the ceiling. The thermal cable is laid directly above the source of danger, so that it (the thermal cable) is exposed to hot air in the event of a fire, or under any horizontal surface that will cause the same radial spread of heat as the ceiling of the room in which the protected object is located.

In some cases, it is very important to detect overheating, which can cause equipment failure or fire. A typical example is the protection of electric motors or conveyor rollers, the roller bearings of which overheat and jam.

The advantage of the Protectowire thermal cable is that it can be installed close to a critical part of the protected object, which ensures rapid response of the detector.

Laying the detector route

All Protectowire Linear Heat Detector models have been tested by Underwriters Laboratories (UL) and/or Factory Mutual Research Corporation (FM). Based on the results of tests carried out in accordance with the requirements of testing standards established by certification bodies, the maximum permissible distances between thermal cable laying lines relative to the maximum detector coverage area for various applications were determined.

Maximum distance between Protectowire thermal cable runs.

When installing a thermal cable outdoors, it is very important to keep in mind that the distances included in NPB 88-01 represent the maximum allowable distance between sections of the thermal cable and should be used as a starting point for designing the location of the detectors. Depending on specific application conditions, such as ceiling design and height, physical obstructions, air currents, or local fire code requirements, the maximum permissible distance between thermal cable runs may be less. The final route and distance between the thermal cable lines are determined based on the results of an engineering assessment.

Installing Protectowire thermal cable on smooth ceilings

When installing thermal cables on smooth ceilings, the distance between parallel sections of cables should not exceed the maximum permissible value specified in NPB 88-01. Thus, the thermal cable should be laid at a distance of no more than 1/2 of the established permissible value from all walls (the distance is measured from the right corner) or ceilings protruding no more than 50 cm, as shown in the figure:

Design with beam floors

In structures with beam floors, etc. heat falls freely along the beams. However, horizontal heat distribution is difficult due to the beams, so in this direction the distance between the thermal cable lines should be less. The thermal cable is laid along the underside of the beams, the distance between all thermal cable lines parallel to the beams should not exceed 50% of the distance between the cable lines laid on a smooth ceiling

Beam structure

If ceiling beams protrude no more than 100 mm, the ceiling is considered smooth; if more, the thermal cable is laid from the right corner at a distance of no more than 2/3 of the distance when installed on a smooth ceiling. If a beam extends downward from the ceiling for a distance of more than 50 cm and less than 2.4 m at the center, each compartment formed by the beams must be protected separately.

"Dead zone

Warm air rises in a stream from the source of the fire to the ceiling, spreading radially. As the air cools, it begins to sink. The corner where the ceiling and two adjacent walls, forms an area called the “dead” zone. In most fire cases, this dead zone is a triangle with sides 10 cm along the ceiling (measured from the corner) and 10 cm down the wall. Do not install Protectowire thermal cable in this area!

Sloping ceilings

In a room with a sloping ceiling or gabled roof, one or more Protectowire linear heat detectors should be installed no more than 0.9m from the highest point of the roof, measured horizontally. The distance between additional Protectowire thermal cable lines, if installed, is determined based on the horizontal distance measured when projecting down from the ceiling and taking into account the ceiling design.

Extension of thermal cable

The variety of Protectowire linear heat detector designs and braided materials provide resistance to a variety of chemicals, liquids and weather conditions, making the cable suitable for a wide range of applications.

Since it is not always possible to accurately determine the effectiveness of the negative impact of aggressive environments on a thermal cable, we recommend, if possible, testing samples at the installation site of the system to determine whether or not the selected thermal cable models are suitable for given environmental conditions.

When designing a detection system for outdoor use, solar radiation exposure must be taken into account. Direct hit sun rays or so-called "total radiation" can lead to heating of the cable or mounting surface to a temperature above the permissible maximum ambient temperature or sensor temperature threshold.

Therefore, preventive measures are very important, such as a protective shield over the cable to reduce the temperature to acceptable values. In addition, the screen will slow down the destruction of the protective braiding of the thermal cable under the influence of solar radiation. In the EPN and EPR thermal cable models, a special inhibitor is added to the material from which the protective braid is made to protect against ultraviolet radiation and extend the service life of the detector.

When using a thermal cable outdoors, all connections using the recommended splicing method or through terminals must be made in appropriate junction boxes. If the cable is installed in high humidity conditions, all connections are made by splicing using PWSC or PWS conduit and SFTS insulating tape.

Warnings

The linear heat detector is made of durable material, but it can be damaged if squeezed or punctured. The results of such damage may not be externally visible on the conductor and may not be immediately apparent, but damage to the outer protective braid or mechanical stress on the conductor during installation may later cause false alarms.

Therefore, during installation you CANNOT:

Leave the cable on the floor, walk on it, or place a ladder on it during installation;

Use non-original fastening devices unless approved by The Protectowire Company;

Lay the thermal cable in places where there is a risk of mechanical damage during technological processes;

Do not overtighten the fasteners, as this may destroy the outer protective braid and the inner insulating layer and, as a result, cause false alarms. All fastenings must allow the wire to compress and expand with temperature fluctuations;

It is normal to stretch the thermal cable too much; some “sagging” of the wire between the fasteners is normal;

BEND THERMAL CABLE AT AN ANGLE 90°;

Use pliers or tongs to bend the thermal cable. All bends are made only by hand, the bend radius should not be less than 6.5 cm;

Use wire nuts or other similar devices. All connections must be made through Protectowire terminals and/or pigtails;

PAINT THE LINEAR HEAT DETECTOR.

This article makes an attempt to explain in as much detail as possible the structure and principle of operation, as well as the methods and scope of application of a linear thermal fire detector (thermal cable) in automatic fire alarm systems and in automatic installations fire extinguishing

Chief Project Engineer of ASPT Spetsavtomatika LLC

V.P. Sokolov

At enterprises of the oil and gas complex, in metallurgical and chemical production, in cable collectors and channels, transport and technological tunnels when creating automatic fire alarm systems and fire extinguishing systems, one often has to deal with difficult operating conditions for this equipment. Explosion and fire hazardous areas, the presence of moisture, abrasive dust, increased pollution, low temperatures or sudden temperature changes, as well as aggressive environments dictate strict requirements for automatic fire detectors and their selection.

According to the operating conditions of automatic fire alarm system equipment, all protected objects can be divided into:

— for objects with normal operating conditions;

— for facilities with difficult operating conditions;

- for special objects.

Normal operating conditions include interior spaces protected object, which are heated during the cold season. There is no dust, presence of aggressive media and abnormal heat sources.

Objects with severe operating conditions are objects with negative temperature differences, both negative and high positive, with the constant presence of condensation due to temperature and humidity changes, with increased dust (solid, abrasive and water suspension) and objects with aggressive environments.

Special objects are objects that have explosive operating conditions.

The unique design of the linear thermal fire detector (SafeCable LHD thermal cable) allows it to be used to protect all of the above objects without exception. It is under these conditions that a linear thermal fire detector ( SafeCable thermal cable LHD) has invaluable advantages.

Operating principle of the SafeCable LHD thermal cable.

Linear thermal fire detector (SafeCable LHD thermal cable ) consists of two steel conductors manufactured according to special technology, each of which has an insulating coating of a heat-sensitive polymer. Steel conductors with an insulating coating of heat-sensitive polymer are twisted to create a spring force between them, then wrapped with insulation and braided to protect them from exposure to harsh environmental conditions. A linear heat fire detector is a cable that allows you to detect a heat source anywhere along its entire length, i.e., it is a single continuous sensor. When the critical temperature is reached, the thermistor material softens and the metal conductors begin to contact each other, thereby initiating a fire alarm. For the thermal cable to operate, you do not need to wait for a certain length of section to heat up. The SafeCable LHD thermal cable is a maximum heat detector and therefore allows an alarm to be generated when the temperature threshold is reached at any point along the entire length of the linear thermal fire detector.

SafeCable LHD thermal cable device (see Fig. 1).

Metal cores with special coating:

— steel provides tensile strength;

— copper increases electrical conductivity;

- tin for corrosion resistance.

Sensitive polymer:

- heat-responsive shell.

External coating:

- polypropylene;

- nylon.

Cable:

— the shell, depending on the type of thermal cable, has different colors

- outer diameter (3.2mm);

– flexible enough for installation.

There are five types of linear thermal fire detector (SafeCable LHD thermal cable), differing in temperature response threshold and having three options for external protective coating, differing in physical and chemical properties.

Technical characteristics of the outer coating (shell) of the SafeCable LHD thermal cable:

— the thermal cable with a general purpose coating has a very durable extruded outer protective PVC sheath, providing reliable protection thermal cables when working in almost any environmental conditions. The thermal cable sheath has fire and moisture resistance properties, and also has sufficient flexibility at low ambient temperatures. Thermal cable with a general purpose sheath is well suited for protecting residential and commercial buildings, as well as industrial facilities;

— a thermal cable coated with polypropylene, marked with the letter “P”, has a durable outer shell that is resistant to ultraviolet radiation, is characterized by high elasticity, resistance to abrasion, resistance to atmospheric conditions and high reliability of operation at high ambient temperatures. Resistant to acids, aggressive environments, oils and petroleum products. Designed for wide application in industry;

- thermal cable marked with the letter “N” with a coating consisting of a two-layer sheath, internal PVC layer and outer layer made of nylon. This thermal cable is specially designed for industrial use eg for the protection of conveyors where abrasion resistance is of greatest importance. In principle, protection against abrasive dust is provided mainly by the outer protective layer of nylon, while maintaining electrical and mechanical properties.

Technical characteristics - SafeCable LHD thermal cable

- Thermal cable diameter

- Bending radius, not less

- Maximum voltage

- Thermal cable resistance (R)

- Response temperature (°C):

- Breakdown voltage (Uv)

- Change in thermal cable resistance depending on temperature

- Minimum working length thermal cable

- Maximum working length of thermal cable

- 3.2mm.

— 6.8kg/305m.

- 76.2mm.

— ~ 30V, = 42V.

- 0.164 Ohm/m.

— 68°, 78°, 88°, 105°, 180°

— 1000 V.

— 1% at 5 degrees.

— 0.5 m.

— 3000m.

Attention: The SafeCable LHD thermal cable is a fire detector with a normally open contact. All rules and regulations of SP 5.13130.2009 for a point heat fire detector with a normally open contact in accordance with Table 13.5 automatically apply to the thermal cable.

Copy from the set of rules SP 5.13130.2009.

13.6 Point heat fire detectors.

13.6.1 The area controlled by one point thermal fire detector, as well as the maximum distance between the detectors, the detector and the wall, except for the cases specified in clause 13.3.7, must be determined according to table 13.5 but not exceeding the values specified in the technical specifications and passports for detectors.

Table 13.5

13.6.2 Thermal fire detectors should be located taking into account the exclusion of the influence on them of thermal influences not related to fire.

13.7 Linear thermal fire detectors.

13.7.1 The sensitive element of linear and multipoint heat fire detectors is located under the ceiling or in direct contact with the fire load.

13.7.2 When installing non-cumulative detectors under a ceiling, the distance between the axes of the detector’s sensitive element must meet the requirements of Table 13.5.

The distance from the sensitive element of the detector to the ceiling must be at least 25mm.

Currently, there are several types of linear thermal fire detectors on the Russian market, which are structurally different from each other:

— The first type is semiconductor This is a linear thermal fire detector in which the wires are coated with a substance having a negative temperature coefficient as a temperature sensor. This type of thermal cable only works in combination with an electronic microprocessor unit management. When any section of the thermal cable is exposed to temperature, the resistance at the points of influence changes. Using the control unit, you can set different temperature response thresholds. After a short exposure to temperature, the cable restores its functionality. The design of the thermal cable does not functionally have the ability to measure the distance to the trigger point. The maximum working length of this type of thermal cable is about 300 m.

— The second type is mechanical This is a linear heat fire detector, which uses a sealed copper tube Ф=6mm as a temperature sensor. (capillary) filled with inert gas and connected to a pressure sensor. When any part of the sensor tube is exposed to temperature, the internal gas pressure changes. The pressure sensor registers this change and transmits the signal to the microprocessor electronic unit for processing. This type of linear thermal fire detector is reusable. Structurally, this type of thermal cable is a maximum differential fire detector. The length of the working part of the sensor's copper tube is limited in length from 20 to 130 meters.

— The third type of multipoint heat fire detector is a linear heat fire detector, which uses a twisted pair of wires as a temperature sensor with thermocouples included in it at a distance of about 50 cm from each other. The operating principle of a thermal cable of this type is based on the summation of emf. from individual thermocouples. Due to the spread of heat throughout the volume of the protected room during a fire, an increase in temperature will be observed at the locations of each thermocouple. Thus, the sensor provides summation of heat dissipated throughout the room. The receiving unit converts the received signals and compares them with the alarm parameters stored in its memory and the specified temperature response thresholds. If these limits are exceeded, the device issues an alarm to the fire panel. The sensitivity of the sensor depends on the number of sensitive elements located in one room. Therefore, when designing fire alarm systems, it is necessary to take into account that the sensitivity of the detector depends on the length of its sensor. This type of linear thermal fire detector is reusable. Structurally, this type of thermal cable is a maximum differential fire detector. The length of the working part of a multipoint sensor has a length limitation of more than 300 meters.

— The fourth type is optical This is a linear thermal fire detector that uses a fiber optic cable as a temperature sensor. The operating principle of an optical linear sensor is based on a change in the optical transparency of the sensor depending on changes in temperature. When light from a laser hits an area of fire, some of it will be reflected. The processing device determines the power of direct and reflected light, the rate of its change and calculates the value of the temperature change and the location where it occurred. This type of linear thermal fire detector is reusable. It only works in conjunction with an electronic microprocessor control and data processing unit. Maximum length optical sensor can reach up to 10 kilometers or more (depending on the quality of the optical fiber). This type of thermal cable requires qualified specialists for installation and maintenance.

— Fifth type electromechanical This is a linear thermal fire detector, which uses a heat-sensitive material applied to two mechanically stressed wires (twisted pair) as a temperature sensor. Under the influence of temperature, the heat-sensitive layer softens and the two conductors are short-circuited. A variation of this thermal cable is a linear thermal fire detector with three heat-sensitive conductors having different response thresholds under the influence of temperature (68.3°C and 93.3°C). Thermal cable different companies manufacturers may have different internal resistance of steel conductors from 0.164 Ohm/m. up to 0.75 Ohm/m. The internal resistance of steel conductors determines the maximum possible working lengths of a thermal cable; this dimension corresponds to lengths from 1500 m. up to 3000m. Due to the presence of internal resistance of the conductors, it became possible to measure the distance to the trigger point of the thermal cable under the influence of temperature. Structurally, such a device is a very sensitive electronic digital ohmmeter. But if you do not need this option, then the thermal cable can work with all fire control panels that work with normally open point fire detectors. It is this type of linear thermal fire detector (thermal cable) that we are considering in this article.

Any point taken on an electromechanical type thermal cable is an independent point thermal normally open fire detector. Thus, on one meter of fire cable we have dozens, if not hundreds, of point heat fire detectors. If you strictly follow the requirements technical specifications SafeCable LHD thermal cable, then the minimum lengths into which the thermal cable can be divided should be 0.5 m. Let's take 10m as an example. thermal cable and divide it into 20 sections of 0.5 m each. We get a fire alarm loop with twenty linear heat fire detectors (in the form of small segments). The only question is why divide it into segments and then connect it together into a whole, if the thermal cable itself carries two functions, it is a linear (multipoint) heat fire detector (sensor) and a linear cable connecting itself. This one may be more expensive, but the reliability of its operation without connections will be much higher.

At the ends of the thermal cable, it is necessary to retreat 10 cm. This is an area of incorrect operation of the thermal cable due to partial dissolution of the twisted steel conductors of the linear thermal fire detector. There is a very high probability that the mechanical twisting force will not be enough to short the conductors together.

At long lengths linear thermal fire detector used (SafeCable LHD thermal cable), for example, more than six hundred meters, it is necessary to take into account the internal resistance of the thermal cable itself, which must be subtracted from the terminal resistor in the fire loop. So the internal resistance of one meter of SafeCable LHD thermal cable is 0.164 Ohms, and six hundred meters will be 98.4 Ohms. If the value of the terminal resistors varies by 10-15%, which we use during installation and a terminal resistor, for example 2.4 kOhm, the value of which depends on the design of the device, plus the resistance of the thermal cable, we can get a loop break signal. If the resistance of the thermal cable is large, it must be subtracted from the terminal resistor.

The SafeCable LHD thermal cable, when the initial section is closed, when exposed to a source of fire, produces a dry contact without resistance, therefore, in order for the control panel not to issue a short circuit signal, additional resistance is necessary. Depending on the fire alarm station used, the additional resistance at the beginning of the section can range from 500 to 1200 Ohms. The additional resistor “Rd” must be subtracted from the terminal resistor of the alarm loop.

Let's look at some features of installing an electromechanical linear heat fire detector (thermal cable):

- When laying it indoors along the ceiling and walls, the thermal cable must be at least 25 mm away from any surface, excluding attachment points. so that the mounting surface does not act as a cooling radiator.

- In the case when a thermal cable is used to protect electric motors, transformers and power distribution of cable collectors, the cable should be attached as close as possible to the protected surface. Surfaces must be in contact.

- When installing a thermal cable outdoors, it is necessary to organize protection in the form of a canopy made from a 5x5mm corner. made of metal or PVC for protection from rain, snow, icicle formation, wind and direct sunlight, especially in summer.

- When protecting steam rooms and saunas, hide the thermal cable in special open niches, protecting it from direct contact with hot steam or air when the heat is applied.

- Select the temperature threshold for the thermal cable to be 35 degrees higher than working temperature in the protected area and the maximum possible positive temperature outside. For saunas, for reliability, it is necessary to take 60 degrees higher than the operating temperature because the heat generation in the sauna is cyclical.

- To avoid false alarms, protect the ends of the thermal cable from moisture and other solvent or conductive fumes using appropriately protected mounting boxes.

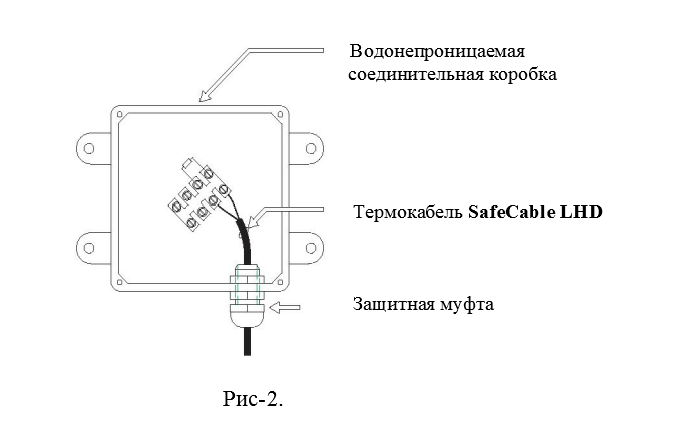

- Attaching the thermal cable with a simple connecting wire or with an end-of-line resistor due to design features carried out through terminal connections. Moreover, the terminal block in the mounting box must be rotated and be at an angle of 45 degrees to the axis of the inlet hole of the mounting box (see Fig. 2). This position prevents the steel cores of the thermal cable from being pulled out of the terminal block clamps when the thermal cable is rocked or twisted along the axis.

- The most reliable connection of a thermal cable in the installation box is to twist the steel ends of the thermal cable into rings of a certain diameter under the terminal screw (see Fig. 3). After that, this mounting box is filled with a special plastic mastic to protect the terminal block clamps from an aggressive environment. The plasticity of the mastic must correspond to the climatic conditions of work. If repairs are necessary, the mastic coating should be easily removed from the installation box.

- When attaching the thermal cable, do not apply strong mechanical tightening, so as not to mechanically trigger the thermal cable, that is, short circuit it.

- When protecting rooms with a ceiling height of more than 9 meters, the distance between parallel threads of the thermal cable is reduced to two meters (manufacturer’s recommendation). This deviation from SP 5.13130-2009 requires mandatory approval in the form of special technical specifications(STU) with local fire inspection authorities. Depending on the functional purpose of such objects according to the requirements fire safety Additional compensation measures for fire protection may be included.

Once upon a time, the only supplier of electromechanical linear heat fire detector (thermal cable) to the Russian market was the Protectowire company. At the moment there are several such companies, including our own manufacturers of this type of fire equipment. One meter of thermal cable, depending on the manufacturer, costs from 200 to 600 rubles and more. If we consider a meter of thermal cable as a point heat fire detector, then the price seems to be not so high. But the design of the thermal cable is original because it is not only a linear thermal sensor, but also a cable that connects itself. This means that the thermal cable has its own niche in the automatic fire alarm system, where only the thermal cable can be used as a thermal fire detector.

Here are some interesting solutions for using thermal cables.

Tunnels.

Technological and transport tunnels are extremely complex engineering and technical complexes and require active fire protection special requirements. To ensure normal operating and maintenance conditions for the tunnel, as well as create conditions for effective fire suppression in conditions emergency(emergency) and emergency evacuation of people a whole complex is being created fire prevention measures in an active fire protection system. A road transport tunnel is extreme conditions operation of fire equipment, large crowds of people and cars (human factor), low temperatures in winter, variable humidity, dust, aggressive environment from exhaust gases, vibration and other man-made influences. That's why the best solution For any transport tunnels there is a thermal cable. As an example, we can take the Lefortovo and Gagarin tunnels in Moscow, which are already protected by an electromechanical thermal cable. In automobile tunnels, a linear thermal fire detector is installed on the ceiling directly above the roadway in accordance with the requirements of the rules SP 5.13130-2009. The cable manifold and cable risers are also protected with a thermal cable. The choice of the type and temperature of the thermal cable is determined by the technical conditions.

The thermal cable in the tunnels is secured using steel cables stretched along the roadway. Due to low temperatures and the formation of ice, constant drafts and wind, the cable with the thermal cable can swing, so special attention must be paid to securing the cable in the installation box. We have already talked about this above. Depending on the season of heat or cold, the cable may sag or shorten. In order for the tension to always be the same, it is necessary to use a device in the form of a metal weight that pulls the cable through a small pulley. The load must be in a special receiving cup that prevents the load from accidentally falling down.

Next to the Gagarinsky road transport tunnel there is a railway transport tunnel. Another problem arose there. Diesel locomotives run through this tunnel. The exhaust pipe of the diesel locomotive is located approximately one and a half meters from the ceiling of the tunnel. As it turned out, the exhaust gases from it have a fairly high temperature of up to 400°C, which could lead to false operation of the thermal cable, especially when the train moves slowly in the tunnel. The solution was found in the form of a metal corner 50x50mm. It was fixed at a short distance from the tunnel ceiling with an angle downwards. The thermal cable itself was placed inside the corner on a special mount so that it would not come into contact with the surface of the corner. A metal corner protected the thermal cable from below, breaking the flow of hot air to the sides, but this did not prevent the thermal cable from operating in a real fire, when the heat from the source of the fire rose upward and filled the volume of the tunnel near the ceiling.

Entrance halls.

Large entrance halls administrative buildings There are always challenges in balancing fire protection and lobby design requirements. Therefore, as a rule, false ceilings are closed tightly with plasterboard, making it impossible to make special hatches in them for servicing fire detectors. However, this space is being filled with technological equipment and especially cable networks. The fundamental solution to this issue was the use of a linear thermal fire detector (thermal cable) to protect the space of a false ceiling covered with a continuous layer of plasterboard. The ends of the sections of thermal cables protecting the false ceiling are brought to a special place where a hatch for maintenance is made, and the thermal cables are connected to the fire alarm system there. The thermal cable does not require maintenance and can be located behind a false ceiling for decades, performing its main functions of fire protection.

Aircraft parking hangars.

Hangars for parking and servicing large aircraft have a complex engineering design with huge spans and are unique and expensive objects. Water is used to protect these structures from overheating in case of fire. As an incentive system for turning on water irrigation metal structures and farms a thermal cable is used. The thermal cable is located in metal pipes, and the pipes themselves are tightly pressed to the surface of the trusses or welded to them. In case of fire, cooling water supply ceiling structures will be carried out if metal trusses, warm up to the operating temperature of the thermal cable, which is a maximum of 180°C. There is a critical temperature for the durability of metal under load, after which the metal is released and the structure begins to deform and then collapse under its own weight. This solution to use a linear thermal fire detector (thermal cable) in a pipe does not comply with the accepted requirements of SP 5.13130.2009 for the fire alarm system. This decision rather relates to the technology of protecting ceiling truss structures and the method of using a thermal cable as a thermal sensor.

Electrical diagrams for connecting an electromechanical thermal cable to fire alarm devices.

Any device that uses thermal fire detectors with normally open contacts can be used as a fire alarm receiving and control station. In projects where thermal cables with lengths of up to 3000 meters are used (for example, cable collectors or conveyors), it is effective to use special devices with a digital indication of the distance to the trigger point.

When using an electromechanical linear heat fire detector in explosive areas, in accordance with existing standards between receiving device and an intrinsically safe barrier must be installed with the thermal cable. The optimal solution for protecting such premises would be to lay a thermal cable from a room with normal conditions into the protected room and exit back. So we endure the montage electrical connections to a neutral room.

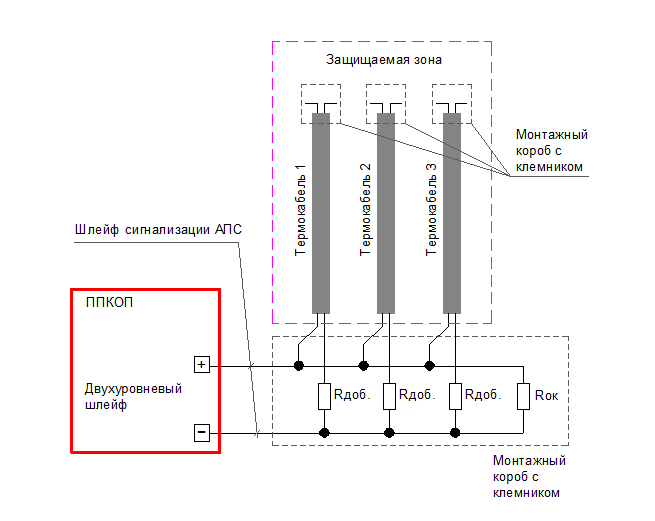

There are three options for connecting an electromechanical thermal cable to fire alarm loops:

— for two-level fire alarm loops;

— for single-level fire alarm loops;

— for polar fire alarm loops (type PPK-2, SIGNAL, etc.).

After an electromechanical linear thermal fire detector is triggered due to a fire or mechanical damage, it is necessary to restore the functionality of the thermal cable. This is achieved by biting out the damaged area and replacing it with regular wire. To find a point short circuit special devices are used. The thermal cable is disconnected from the control panel and connected to the sound generator. Next, the specialist, using a special sensor, walking along the linear heat fire detector (thermal cable) removes sound signal. At the short circuit point the sound becomes continuous. The accuracy of short circuit detection is up to 1cm. A less accurate way to find a short circuit in a thermal cable, but also the most accessible, is to measure the resistance with a conventional digital ohmmeter. Determination accuracy in in this case within five meters.

Figures Fig. 4, Fig. 5, Fig. 6 show typical electrical diagrams for connecting a thermal cable to fire alarm devices.

Diagram for connecting a thermal cable to a two-level fire alarm loop.

Diagram for connecting a thermal cable to a single-level fire alarm loop.

Diagram for connecting a thermal cable to a bipolar, single-level fire alarm loop.

The linear thermal fire detector (SafeCable LHD thermal cable) is easy to design, install, operate and maintain. The thermal cable has shown its reliability in difficult conditions and over time. It should be noted that the need for a linear thermal fire detector (thermal cable) in the Russian market is determined by its unique capabilities in the field of fire safety.

And in conclusion, if you have any questions about the use of thermal cables or would like to receive more detailed information, the specialists of ASPT Spetsavtomatika LLC are always ready to provide assistance, as well as conduct trainings and individual project support.

Reliability and high quality are our main priority.

Thermocable ProReact Digital LHD Linear Heat Fire Detector

Thermocable ProReact Digital LHD is a high-tech linear thermal fire extinguishereater,which has been in production for over 35 years. Modern advanced technology ProReact Digital, used in the production of linear detectors, allows Thermocable to always be one step higher and have a huge advantage over all linear heat detectors that are presented on the Russian and world markets.

The ProReact Digital linear thermal fire detector is designed to determine the fire point along the entire length of the sensitive element (thermal cable). The ProReact Digital linear heat fire detector is a twisted-pair thermal cable with trimetallic conductors, which are enclosed in polymer coating with sensitivity to temperature conditions. Two conductors twisted together in a special way to maintain mechanical tension and are enclosed in an outer protective covering. When the temperature exceeds the set value, the polymer melts, the conductors close and issue a signal directly to the fire alarm panel or to the fire alarm panel through the interface module.

ProReact Digital product line includes:

Classic - ProReact Digital Available in PVC sheaths, nylon sheaths, polypropylene sheaths, and an additional protective sheath made of steel braid. Sensitivity temperature +68°С, +78°С, +88°С, +105°С, +185°С.

Exclusive -PlusProReact Digital Plus ng FRLS , ng FRHF , low smoke, no halogen emissions Available in LSZH sheaths, and in an additional protective sheath steel braid. Sensitivity temperature +65°C, +75°C, +85°C, +110°C.

Exclusive - ProReact Digital VHT Cable high temperature Available in silicone shells and an additional protective steel braided shell. Sensitivity temperature + 235 °C.

|

Name |

Temperature sensitivity |

Shells |

Applications |

|

ProReact Digital |

68°С, +78°С, +88°С, +105°С, +185°С. |

PVC, nylon, polypropylene, additional steel braided sheath |

|

|

ProReact Digital Plus ng FRLS, ng FRHF |

65°С, +75°С, +85°С, +110°С |

LSZH low smoke, no halogen emission, resistant to ultraviolet radiation and aggressive environments, additional sheath with steel braid |

Normal environmental conditions, resistant to ultraviolet radiation and aggressive environments, additional protection from mechanical damage. |

|

ProReact Digital VHT Cable |

High temperature environment |

Thermocable ProReact Digital LHD protects objects:

Benefits of Thermocable ProReact Digital LHD

- Saving price in rubles according to a fixed price list. The price does not depend on exchange rates.

- Two connection options: Via an interface module and directly to the fire alarm panel.

- Maximum cable length - 3000m with direct connection and using interface module

- Is an analog replacement for all those presented on Russian market thermal linear fire detectors.

- Compatible with any fire alarm panel.

- Guaranteed sensitivity along the entire cable length.

- Minimum bending radius reduced to 50 mm

- Sensitivity range from +68,+88,+105 ,+185 degrees C (classic thermal cable)

- Exclusive sensitivity range from +65°C, +75°C, +78 +85°C, +110°C degrees C

- Sheath: PVC, nylon, polypropylene and steel braid, LSZH, silicone.

- Used in environments with aggressive factors.

- UV protection for outdoor use

- Protection against mechanical damage

- Noise protection

- Increased level of chemical protection and protection in alkaline environments

ProReact Digital technology

Tri-metal conductor made of sprayed steel:

Copper, thanks to which it was possible to significantly increase electrical conductivity and reduce resistance,

Tin used for corrosion resistance.

Inner shell:

Heat sensitive polymer.

Application area

A typical solution for using thermal cables is premises with a large area or length, as well as hard-to-reach areas that require 100% coverage and protection, extended areas, areas with an aggressive environment. The heat detector is resistant to dust, humidity, chemical reagents, high and low temperatures, can be used in explosive areas, easy to install, does not require maintenance. Service life - at least 30 years.

Interface module THERMOCABLE_MIP2

The firefighter interface module “THERMOCABLE_ MIP2I” is a two-zone module for monitoring one or two zones of a linear thermal fire detector. When exposed to high temperatures sensing element- linear thermal fire detector, due to overheating or a fire in any of the two zones, MIP2I automatically calculates the distance to the point of overheating on the linear thermal fire detector and displays the resulting value in meters. The two zones operate independently of each other, and each zone has a separate alarm and normally conducted fault output. MIP2I is designed for installation between a linear thermal fire detector and an addressable or addressless fire alarm control panel. MIP2I has power, failure and alarm indicators responsible for each individual zone. MIP2I can also be connected to automated system management technological processes production using a two-wire RS-485 Modbus RTU output.

Interface firefighter module “THERMO CABLE_ MIP2I” with indication of the exact location of the fire with the function of connecting two or one loop of a linear thermal fire detector ProReact Digital (hereinafter referred to as the module and/or abbreviation MIP2I).

Main features of the MIP2I module:

- The connection of two loops of a linear thermal fire is notified

- Two operating modes: independent and two-threshold

- Independent mode provides independent control over the operation of each linear thermal fire detector connected to MIP2I, which allows you to connect to the device both linear thermal fire detectors with similar characteristics (of the same sensitivity temperature, in the same type of shell) and linear thermal fire detectors with different characteristics. sensitivity temperatures and different shells). In this operating mode, if one of the loops catches fire, the device will give a “FIRE” signal and determine the distance to the source of fire.

- Dual threshold mode provides joint control of two zones of a linear thermal fire detector with the ability to issue a preliminary fire signal and a “FIRE” signal. In this mode, the “FIRE” signal is given only when two loops of a linear thermal fire detector connected to MIP2I are triggered simultaneously. When only one loop is triggered, the device determines the distance to the source of a possible fire, but does not signal a fire. This mode is designed to protect against false alarms.

- MIP2 operates independently or with connection to the fire alarm panel.

- Supports MODBUS protocol

- LCD display with indication

- There are two options for connecting a linear heat fire detector: directly to the MIP2I and connecting via a leading-connecting cable, which allows you to reduce the number of linear heat fire detectors, as well as install the MIP2I in any place convenient for the user. The connecting cable is calibrated automatically when the system is first installed.

- Line heat fire fault control is notified.

- Possibility of connecting one line of a linear heat fire detector.

Specifications firefighter interface module

"THERMO CABLE_ MIP2I"

|

Name |

Options |

|

Dimensions |

H180mm x W120mm x D60.5mm |

|

Protection class |

N4MA4, 4X (IP65) |

|

Coating |

Light grey, transparent lid |

|

2 lines, 16 characters, backlight, display shows zone status |

|

|

Operating voltage |

12VDC - 36VDC |

|

Normal operation |

<10мА <4мА |

|

Both alarms are activated and LCD backlight is on |

<40мА <15мА |

|

Temperature Range |

|

|

Accommodation |

5mm ascending clamp connection |

|

Information outlet |

Two-wire RS-485 Modbus RTU |

|

Signaling |

2x voltage-free relay contacts C-form Max. voltage 220 V DC / 250 V AC Max. current 2A Max. commutation power 60W, 62.5VA |

|

Max. voltage 35 V DC Max. current 80mA |

The THERMO CABLE_ MIP2I module works in conjunction with the ProReact Digital linear heat fire detector.

Connection diagram

Certificates

|

|

|

|

Mounting accessories

| Name | for replacement | Availability/delivery period | Description |

| TH-1000 | ZB-4-QC-MP |

IN STOCK IN MOSCOW |

Mounting box |

| TH-100S | analogue SR 502 |

IN STOCK IN MOSCOW |

Germovvod (galvanized steel) |

| TH-100N |

IN STOCK IN MOSCOW |

Germovvod (nylon) | |

| WAW-N |

IN STOCK IN MOSCOW |

Nylon Mounting Clamps | |

| OHS-1 |

IN STOCK IN MOSCOW |

Zinc mounting clips | |

| BC-2 |

IN STOCK IN MOSCOW |

Clamp for mounting on a beam. Steel. Additionally required TH-101N clamps and TH-101-2 pins | |

| BC-3 |

IN STOCK IN MOSCOW |

Clamp for mounting on a beam. Cink Steel. Additionally required TH-101N clamps and TH-101-2 pins | |

|

IN STOCK IN MOSCOW |

Punch pin | ||

| HPC-2 |

IN STOCK IN MOSCOW |

Cable tray clip | |

|

IN STOCK IN MOSCOW |

Cable tray clip | ||

|

IN STOCK IN MOSCOW |

Clip for cable tray. Material thickness 4-6.4 mm | ||

| PM-3A |

IN STOCK IN MOSCOW |

Pipe clamp with two loops | |

|

other fasteners |

Wiring diagram for a linear heat fire detector without using the Thermocable ProReact Digital LHD interface module (direct connection)

The Thermocable trade name is directly associated with the production of high-quality thermal cables - linear detectors that respond to temperature changes. The quality of the Thermocable ProReact Digital LHD linear fire detector is confirmed by European, American and Russian certificates. The thermal linear detector Thermocable ProReact Digital LHD is a high-quality analog replacement for all thermal linear fire detectors presented on the Russian market. By purchasing Thermocable you are purchasing real English quality combined with a high-tech modern product.

With the development of technology, new fire-fighting equipment has appeared, where the function of quick, accurate fire detection is performed by linear heat detectors (LTDs).

The primary task of linear detectors is to ensure the safety of premises with permanent or temporary occupancy of people, the preservation and protection of material property from fire in the territories of fire protection facilities.

Thermal cable device

The most convenient fire-fighting heat sensor is a thermal cable. It is used where other devices cannot be installed, for example, in containers with flammable substances, on heating mains, in nuclear reactors.

The design of the linear thermal fire detector or thermal cable has stable functionality, low operating costs, and long service life.

Protecting equipment and objects from fire by controlling the temperature, it generates a certain signal when it changes, making it possible to eliminate the fire without significant material damage.

A modern thermal cable, affordable and easy to use, consists of two twisted trimetallic conductors that are coated:

A modern thermal cable, affordable and easy to use, consists of two twisted trimetallic conductors that are coated:

- of steel. Provides tensile strength;

- copper Electrical conductivity increases, resistance decreases;

- tin. To improve corrosion resistance;

- heat-sensitive polymer.

The two conductors, twisted together to maintain mechanical tension, are additionally encased in a sheath of nylon or polypropylene, providing reliable protection for the cable from UV rays. The shell also increases resistance to aggressive chemical and caustic environments. Resistance to mechanical wear is carried out using a braid of metal or glass fibers. The temperature range of use of the linear heat detector is from ─60 to + 180 ℃, which allows the cable to be used in different climatic conditions.

Operating principle and application

The principle of operation of a thermal cable is based on the violation of the integrity of the insulating material due to overheating under the influence of an increase in ambient temperature. As a result of the destruction of the insulation, the conductors are short-circuited, which sends a signal to the remote control. An alarm signal can be generated on any part of the cable, regardless of its length. When alarming fire factors are detected, the transmission of information by linear heat detectors is a threshold or analog process.

The fire sensor, in accordance with GOST, according to its purpose, can be installed both indoors and outdoors in long open areas. The operating mode of the fire safety system depends on the device of the linear detector. The main technical characteristics are sensitivity, inertia, coverage area (its shape and area), as well as noise immunity.

Wider possibilities are provided by a thermal linear device that has a cumulative effect, where the conductor resistance processing unit can be installed outside the control zone. A heating cable that provides the summation of all hazardous factors is widely used for rapid fire detection at transformer substations, thermal and hydroelectric power plants, and aircraft hangars.

It is installed at oil and gas enterprises, metallurgical and chemical plants, transport tunnels in hard-to-reach, highly polluted, dusty places with an aggressive and explosive environment.

Types of linear thermal sensors

The domestic market of fire-fighting equipment offers models of linear heat detectors that differ in the material of the protective shell, temperature response, monitoring and control system. The manufacturer, focusing on the conditions of use, produces several types of thermal linear fire detectors.

The domestic market of fire-fighting equipment offers models of linear heat detectors that differ in the material of the protective shell, temperature response, monitoring and control system. The manufacturer, focusing on the conditions of use, produces several types of thermal linear fire detectors.

The most widespread are:

- electronic, which does not allow a short circuit, but records the change in resistance when heated. A temperature sensor is a material covering the wires that has a negative temperature coefficient. The cable, acting in conjunction with the electronic control unit, creates different temperature thresholds and easily restores its functionality after short-term thermal exposure;

- reusable mechanical linear heat detector. Temperature control is carried out using an impenetrable long (up to 300 m) metal tube. The tube is filled with gas; when heated, its pressure increases, this is recorded by the control unit;

- conventional single-action linear contact detectors. A polymer sheath is used as a temperature sensor, capable of melting at a certain temperature, applied to two wires twisted together;

- fiber optic linear thermal sensor. A universal optical cable that is distinguished by the rapid detection of various types of fire. The temperature sensor consists of an interrogation device with a laser source and a halogen-free fiber optic cable, which makes it possible to carry out thermal monitoring over a long distance. The factors for using the cable are affordable price, reliability, durability, and ease of installation.

One more type, pyrotechnic, can be distinguished. Such a linear detector can perform fire extinguishing functions. When heated, the pyrotechnic elements fire, open the valves and release the extinguishing agent.

Advanced fire-fighting equipment guarantees fire safety for all public, industrial and administrative buildings.

Popular models

Modern thermal models differ in type, layer of outer protective shell, and conditions of use. The most well-known brands are Protectowire, Pozhtekhnika, Spetspribor, Thermocable, Etra.

Table. Technical characteristics of Protectowire thermal cable

| Designation | Operation logic | Operation temperature, °C | Operating temperature range, °C | Application area |

|---|---|---|---|---|

| PHSC-155-EPC | For one temperature | 68 | -44… +105 | Normal conditions |

| PHSC-190-EPC | 65,6 | |||

| PHSC-280-EPC | 93,3 | |||

| PHSC-356-EPC | 105 | |||

| PHSC-155-EPR | 68 | Aggressive environments | ||

| PHSC-190-EPR | 65,6 | |||

| PHSC-280-EPR | 93,3 | |||

| PHSC-356-EPR | 105 | |||

| PHSC-135-XLT | 57 | Low temperature |

||

| PHSC-6893-TRI | Combined (two temperatures) |

68 — "Attention" 93 — "Fire" |

Getting a double trigger |

IPLT type EPC, manufactured under the Protectowire license, is a universal thermal conductor with a PVC sheath. It is used outdoors when environmental conditions do not require the installation of a conventional heat detector. It has high resistance to dampness, dust formation, and the ability to limit the spread of flame.

The thermal cable retains good bendability. Preserving the condition of the material, the detector does not require maintenance and high costs during operation when exposed to atmospheric influences and UV.

IPLT type XLT is a type of thermal cable specially designed to operate at extremely low temperatures. The detector module with a super durable polymer shell, withstands ─55°C, is intended for use in heat-insulated containers, storage facilities, unheated industrial buildings, and the harsh climatic conditions of the North.

IPLT type TRI - thermal cable, is a unique linear heat detector. A new type of sensor with high chemical resistance, capable of withstanding the destructive effects of aqueous solutions of acids and alkalis, is intended for use in explosive environments. The thermal conductor, protected by a metal woven mesh, is able to withstand electromagnetic radiation and eliminate static electricity from the surface. Requires double-sided grounding during installation.