TOPIC 2: “Fire extinguishing agents and the procedure for their use in case of fire”

To extinguish fires, water, air-mechanical foam, powders, and inert gases are used.

Water, as the main means for extinguishing most combustible materials, can be supplied to the source of a fire in the form of compact jets or in a finely sprayed form. Compact jets are supplied using ordinary fire nozzles, and spray jets are supplied through special spray nozzles or heads of sprinkler or deluge installations. Water can be supplied to the fire using buckets and other containers.

FIRE TRUCKS

All existing fire engines are divided into three groups: main, special and auxiliary.

Within each group, there are types of machines that differ from each other in the design of individual components or the entire machine as a whole. Thus, main purpose fire fighting vehicles include tank trucks, pump trucks, motor pumps, fire trains, ships, airplanes and helicopters. Each type of vehicle has several standard sizes (models), differing in performance, dimensions, weight, etc. Thus, according to the type of base chassis, fire engines can be divided into automobile, tractor, tank and artillery. Based on the type of energy used, there are machines driven by electric motors, internal combustion, hydraulic, pneumatic, etc. Based on the type of control, machines with mechanical, hydraulic, pneumatic and other control systems are distinguished. According to the degree of versatility, the machines are divided into communication and lighting machines, technical service having work equipment, and specialized machines designed to perform only one type of work (motor pumps, ladder trucks, mobile fire monitors, etc.).

Get full textFire tankers and pump trucks

Fire tankers and pump trucks are designed to deliver personnel, water, foam concentrate, firefighting equipment, and supply water or air-mechanical foam to the fire site.

Largest specific gravity Tank trucks account for the production of fire fighting vehicles (over 80%), which, due to their versatility, are widely used in fire departments of all industries national economy and in fire-fighting units of civil defense units and formations.

Tank trucks belong to a group of vehicles that are independent tactical units. They are also used in conjunction with other types of fire engines.

Currently, the domestic industry produces tank trucks of three main types: light - with a base chassis load capacity of up to four tons, medium - with a base chassis load capacity of four to five tons, and heavy - with a base chassis load capacity of over five tons.

Firefighting tankers are mounted on the chassis of regular and off-road trucks. The chassis of the base vehicle is modified to accommodate the installation of a pumping unit, a power transmission of a centrifugal pump, a water tank, a crew cabin and a vehicle body.

Autopumps differ from tank trucks in the absence of a water tank, an expanded set of fire-fighting equipment (in terms of quantity and nomenclature), a large number places for combat crews and an increased capacity of the foam concentrate tank. Truck pumps, as a rule, are used in conjunction with tank trucks, but they can be successfully used independently when extinguishing fires in areas with a widely developed water supply network (natural or artificial), especially in cities and industrial enterprises.

In design, car pumps and tank trucks are similar to each other, since they have the same type of layout and the same unified components - power take-offs and pumping units, other components and systems. The degree of unification of tank trucks and pumps mounted on the chassis of the same vehicle reaches 70%, which greatly facilitates the operation and maintenance of vehicles.

Fire tanker ATs-40.

The tanker (Fig. 1) is mounted on the chassis of a three-axle off-road vehicle.

The tanker has a transportable water supply of 2400 liters, which is enough to operate with one barrel with a nozzle with a diameter of 13 mm for 10 minutes at a pressure of 60 mm of water. Art. or for 8 minutes of operation at a pressure of 30 mm of water. Art.

The stock of transportable foaming agent ensures the production of about 35 m3 of foam with a factor of 10. If the water tank is filled with a foaming agent when operating from an external water source, about 600 m3 of foam can be obtained.

The tanker is equipped with a stationary monitor and high-expansion foam generators.

Basic technical specifications modern fire fighting tankers and pump trucks are given in table. 1. General device fire tanker shown in Fig. 2. The main units in the design of fire-fighting tankers and motor-pumps are: fire pump, vacuum system, fire pump drive, additional cooling system, tanks for water and foam concentrate, heating system for the cabin and tank (tank), water-foam communications control system.

Rice. 1. Fire tanker ATs-40 on ZIL-131 chassis

Technical characteristics of modern fire fighting tankers and pump trucks

Indicators | Tankers and pumps |

||||||

ATS-40(131) 42A | |||||||

Chassis brand | GAZ-66 | ZIL-130 |

|||||

Maximum speed, km/h | |||||||

Total vehicle weight, kg | |||||||

Maximum engine power, l, With. | |||||||

Pump brand | |||||||

Pump performance at a geometric suction height of 3.5 m, l/s | |||||||

Pump shaft speed, rpm | |||||||

Capacities, l: for foam concentrate |

Foam fire fighting vehicles

Foam extinguishing fire trucks are designed to deliver combat crews, fire-fighting equipment, foam concentrates, and technical means for supplying air-mechanical foam to the site of a fire and are used to extinguish fires at oil refineries and petrochemical plants, as well as to extinguish burning oil and petroleum products.

Foam extinguishing vehicles are equipped on an off-road chassis.

To protect small oil depots, foam extinguishing vehicles can be mounted on a chassis with a carrying capacity of 4-4.5 tons, while being armed with a fire pump with a foam capacity of 4.5 to 7 m/min, and have a capacity for delivering foam concentrate to required quantity and associated foam production and delivery equipment.

Get full textTo protect large oil depots, foam extinguishing vehicles are equipped on a chassis with a carrying capacity of 5-7 tons, and to protect oil production and refining areas, foam extinguishing vehicles are mounted on a heavy-duty chassis.

Depending on the type of foam (air-mechanical or chemical), foam extinguishing vehicles are divided into air-foam extinguishing vehicles and chemical foam extinguishing vehicles.

Currently, the AV-40(375) air-foam extinguishing fire truck is being mass-produced (Fig. 7).

It delivers 4,000 liters of foam concentrate to the fire site, from which about 1,000 m3 of air-mechanical foam with a factor of 10 can be obtained.

When extinguishing major fires petroleum products AB-40(375) should be used in conjunction with tank trucks or pump trucks. However, if there is a source of water near the fire site, it is possible independent use car. It can also be used as a fire tanker. Automobile

can work in different climatic zones with annual temperature fluctuations from -35 to +35° C. High cross-country ability allows it to be used in areas with bad roads. Load capacity of AB-5t.

Rice. 7. Air-foam extinguishing fire truck AB

A special feature of the vehicle's layout is the middle location of the pump in the combat crew cabin with the suction pipeline leading forward, under the vehicle's bumper, as well as the use of remote hydraulic control of the main valves of the water-foam communications and the monitor.

A three-legged metal ladder and four-meter suction hoses (Du-150 and Du-75) are placed in special cases under the tank and body pedestals.

On the AB-40(375), in addition to the electrical equipment of the base chassis, there are additionally installed: a spotlight for illuminating the work area, two flashing signal lights.

The fire-fighting equipment is located in the cabin, in the body compartments and is securely secured with special clamps that ensure quick and convenient removal.

The AB-40(375) vehicle is a modification of the AC-40(375) fire tanker and differs from it in the design of the rear compartments of the body pedestals, additional devices to create reliable tightness of the tank, fire-fighting equipment and the design of its attachment points. Such main components as a fire pump, power take-off, additional power transmission, hydraulic equipment, monitor, main valves for water and foam communications, and additional electrical equipment are completely unified.

Using the AB-40(375) vehicle, you can perform the following types of work:

Extinguishing. petroleum products spilled on the ground or in production premises; the fire extinguishing agent is supplied either using a stationary barrel or through hose lines that supply portable foam generators with high-expansion air-mechanical foam;

Extinguishing oil products in tanks by supplying air-mechanical foam through the hoses under the layer of fuel through a special valve in the lower part of the tank, while a glass with an ejector of the UPPS-46 installation is connected to the valve;

Extinguishing oil products in tanks by supplying air-fur. nic high-expansion foam on top of the “mirror” of petroleum products through two foam generators mounted on top of a three-legged metal stairs; the latter can be installed either on the ground or attached to the front bumper of the car.

Fire pumping stations and hose trucks

When extinguishing large fires in areas of natural disasters and nuclear disaster sites, it is necessary to supply a significant amount of water (foam) over long distances. For this purpose, a complex of high-power machines is used: a fire pumping station with a hose truck or a special set of pipelines, self-propelled tracked monitors, as well as army field main pipelines.

Fire pumping station PNS-110 is designed to supply water through main lines to directly power vehicle pumps, mobile fire monitors and air-foam guns, to fill water tankers with water (where there is no running water and water sources are located long distances), as well as to create a water supply when extinguishing large oil fires.

Fire pumping station PNS-110 (Fig. 8) is pump unit, mounted on the chassis of a ZIL-131 car, covered with a rigid metal hood. Under the hood there is an engine (diesel) with a clutch, centrifugal pump PN-110 connected to the engine using a card. nal shaft, as well as systems: fuel, lubrication, cooling and heating, air release and vacuum. The unit has controls pumping unit, instrument panel and components.

The engine is started using an electric starter. Emergency (auxiliary) engine starting is carried out with compressed air.

Rice. 8. Fire pumping station PNS-110:

A - general view; b- rear view; 1 - pump room; 2 - control and measuring instruments of the pump room

Get full textFire hose vehicle AR-2

The fire hose vehicle AR-2 (Fig. 13) is designed for delivery to the fire site of pressure hoses with a diameter of 150, 110 and 77 mm, with a total length of 1340, 1850 and 2200 m, respectively, for laying hose lines while the vehicle is moving, mechanized winding of hoses into rolls , as well as for loading them into the body of a car.

The vehicle is used in conjunction with mobile pumping stations, pump trucks or tank trucks. Laying of hose lines can be done at a vehicle speed of 8-10 km/h. Time for simultaneous laying of two trunk lines from hoses with a diameter of 150 mm, a length of 740 m - about 2.5 minutes. The time for winding two sleeves into rolls, taking into account the installation of the device forks, is about 40 s, and the time for lifting two sleeves into the body is about 25 s.

The ability to equip a vehicle with hoses of three diameters, the presence of a device for mechanized winding of hoses into rolls and their loading into the body, which can be quickly released from the guide posts, as well as the presence of a permanently installed fire monitor provide high tactical capabilities of the vehicle.

The vehicle has a high average speed and can be successfully operated in areas with poor roads and in off-road conditions. It can operate in various climatic conditions at air temperatures from -35 to +35°C.

The hose vehicle is mounted on the chassis of a three-axle ZIL-131 off-road vehicle. A winch is installed in front of the car to pull it out on difficult sections of the road, as well as to provide assistance to cars stuck along the way.

Load capacity of the basic vehicle chassis when operating on mixed roads with various types coverings, including dirt roads and off-road areas, 3.5 tons.

Rice. 13. Fire hose vehicle AR-2 (131):

FIRE PUMPS

Motor pumps are designed to supply water from open water sources and pump water over long distances when extinguishing fires. Simplicity and reliability of designs, simple handling rules make motor pumps indispensable when extinguishing fires in hard to reach places, at national economic facilities, on collective and state farms. Motor pumps are divided into portable and trailed.

Portable motor pump MP-600A consists of a two-stroke carburetor internal combustion engine and a single-stage centrifugal pump, which are mounted on a common frame with handles for carrying the motor pump.

Motor pump capacity - 600 l/min. Engine power at 3000 rpm -9.6 kW (13 hp). When operating, the motor pump consumes 6.8 liters of fuel per hour.

Portable motor pump MP-800A consists of an internal combustion engine and a centrifugal pump. The engine is two-stroke, carbureted at 3500 rpm and develops a power of 17.2 kW (23.5 hp). Hourly fuel consumption - 9l.

The motor pump has a three-mode engine crankshaft speed limiter in idle and water suction modes. The limiter consists of the speed limiter itself, a hydraulic diaphragm sensor and an oil system with an oil compensator.

Filling the suction line and pump with water is carried out vacuum system, consisting of a gas-jet vacuum device mounted on the cylinder head, a hose system and a distribution valve mounted on the pump body. The gas jet vacuum apparatus is driven by compressed air. The gas-jet vacuum device is turned on and off by turning the handle of the distribution valve.

Motor pump MP-1400 is a single-axle trailer on which a ZMZ-451 internal combustion engine and a centrifugal pump are mounted. The four-cylinder carburetor engine develops a power of 51.5 kW (70 hp) at 3800 rpm. The pump, with a suction height of 3.5 m, provides a supply of 1500 l/min at a pressure of 882 kPa (90 m of water column).

The engine and pump are covered with a metal hood, which has two side flaps for access to the engine, instrument panel and control levers. The motor pump is started from the starter.

The pump consists of a housing and a cover with a suction pipe. Impeller it is fixed on the shaft in a cantilever manner. The shaft rotates in two ball bearings, lubricated by oil poured into the pump shaft housing.

The pump consists of a housing and a cover with a suction pipe. Impeller it is fixed on the shaft in a cantilever manner. The shaft rotates in two ball bearings, lubricated by oil poured into the pump shaft housing.

The pump seal consists of three rubber frame seals ASK-38 X 58 X 9, ensuring the tightness of the internal cavity of the pump. Water is sucked in by a gas-jet vacuum apparatus powered by engine exhaust gases.

Rice. 13. Fire motor pump MP-1600. |

Motor pump MP-1600(Fig. 13) is mounted on a single-axle trailer on which the engine and centrifugal pump are installed. The motor pump is covered at the top with a metal hood and at the bottom with a tray. The MP-1600 motor pump is created on the basis of the MP-1400 motor pump design. The ZMZ-451 engine is used as the power unit, with the clutch of which the pump is rigidly connected. The engine is started from a starter powered by a 12 V battery. The motor pump is equipped with a stationary foam mixer for supplying air-mechanical foam. The control and measuring instruments of the pump and motor are located on the instrument panel of the motor pump.

Water is sucked from water sources using a gas-jet vacuum apparatus. The motor pump pump supplies 1600 l/min of water at a pressure of 784 kPa (80 m of water column). Vacuum system control is semi-automatic.

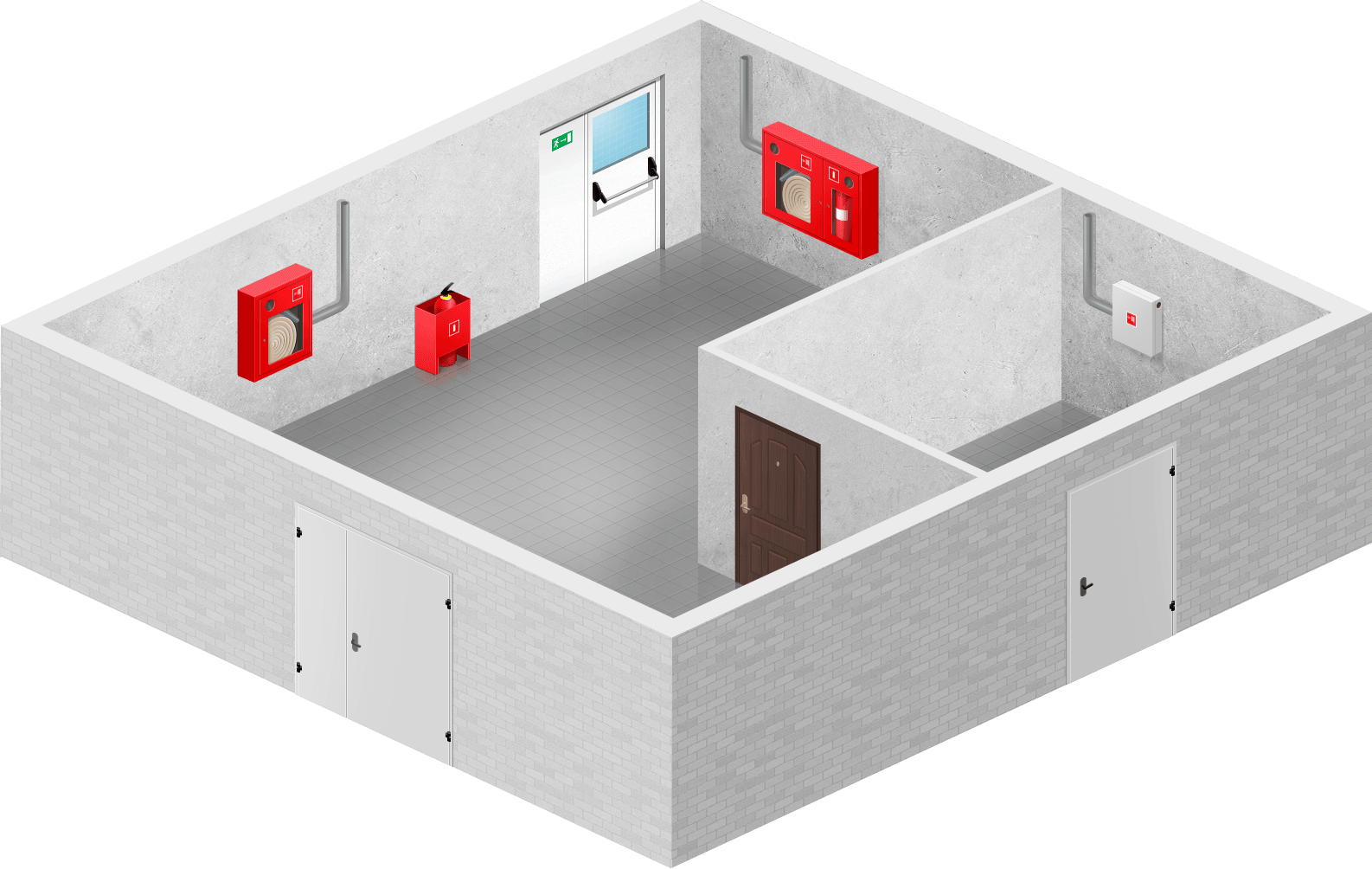

Primary fire extinguishing means are devices, tools and materials designed to localize and (or) eliminate a fire at the initial stage (all types of portable and mobile fire extinguishers, fire hydrant equipment, boxes with powder compositions (sand, perlite, etc.) , as well as fire-resistant fabrics (asbestos fabric, felt, felt, etc.), water, bucket, shovel, etc.). Primary fire extinguishing means must always be at the ready, and posters on the design of fire extinguishers, posters on the application (use) of fire extinguishers, posters on the design and purpose of an internal fire hydrant, a fire shield must be posted in prominent places.

It must be remembered that primary fire extinguishing agents are used to combat fire, but not fire, since it is impossible and even life-threatening to combat a developed fire with their help. Only fighting a fire is feasible for non-specialists, but extinguishing a fire is the work of professional firefighters.

Production, administrative, auxiliary and warehouse buildings, structures and premises, as well as open production sites or areas must be provided with primary fire extinguishing means in accordance with current standards established by industry rules fire safety.

Primary fire extinguishing means should be located in easily accessible places and should not be a hindrance or obstacle during the evacuation of personnel from the premises. It is allowed to install fire extinguishers in cabinets or cabinets, the design of which should allow visual identification of the type of fire extinguisher and quick access to it for use in case of fire. Fire safety posters should be hung in visible, public places.

The use of fire equipment and other fire extinguishing means for household, industrial and other needs is prohibited. In addition to their direct purpose, it is permitted to use fire extinguishing agents in the elimination of natural disasters and catastrophes, as well as in training personnel and volunteer fire units of the facility. For violation of these provisions, officials or other persons are liable, including criminal liability, in accordance with current legislation.

Used or faulty fire extinguishers (damage to the body, socket, safety valves, lack of filling, defect fire extinguishing agent or gas, etc.) must be immediately removed (especially after a fire) from the protected area, from technological equipment and production sites and replaced with serviceable ones. Malfunctions of fire extinguishers, fire hydrants and other fire extinguishing equipment identified during regular inspections must be eliminated as soon as possible.

Basic primary fire extinguishing means:

1. Fire extinguishers:

Fire extinguishers are intended for extinguishing fires in their initial stages, as well as for fire protection small structures, machines and mechanisms.

Fire extinguishers are portable and mobile. Portable fire extinguishers include all types weighing up to 20 kg. Fire extinguishers with a large charge volume (with a mass of at least 20, but not more than 400 kg; may have one or more containers with a fire extinguishing agent) are classified as mobile; their bodies are installed on special trolleys.

Based on the type of fire extinguishing agent used, fire extinguishers are divided into:

Water fire extinguishers (0V);

Powder fire extinguishers (OP);

Foam fire extinguishers:

Air-foam fire extinguishers (AFP);

Chemical foam fire extinguishers (CF) - currently out of production;

Gas fire extinguishers:

Carbon dioxide fire extinguishers (CO);

Freon fire extinguishers (CH);

Combined fire extinguishers.

The most widely used fire extinguishers are carbon dioxide, powder and air-foam fire extinguishers. The set of posters “Primary fire extinguishing agents” contains posters on the design and use of all three types of fire extinguishers.

Based on the principle of displacement of the fire extinguishing agent, fire extinguishers are divided into:

Fire extinguishers are downloadable;

Fire extinguishers with a compressed or liquefied gas cylinder;

Fire extinguishers with a gas-generating element;

Fire extinguishers with thermal element;

Fire extinguishers with ejector.

The posters illustrate the design of injection fire extinguishers, fire extinguishers with a compressed or liquefied gas cylinder and with a gas-generating device - the most common types of fire extinguishers.

According to the possibility and method of restoring the technical resource, fire extinguishers are divided into:

Fire extinguishers are rechargeable and repairable;

Fire extinguishers are not rechargeable.

According to their intended purpose, depending on the type of charged fire extinguishing agent, fire extinguishers are divided into:

Fire extinguishers for extinguishing the fire of solid flammable substances (fire class A);

Fire extinguishers for extinguishing fires of liquid flammable substances (fire class B);

Fire extinguishers for extinguishing fires of gaseous flammable substances (fire class C);

Fire extinguishers for extinguishing fires of metals and metal-containing substances (fire class D);

Fire extinguishers for extinguishing the fire of electrical installations under voltage (fire class E).

Fire extinguishers can be designed to extinguish several classes of fire. Depending on the purpose powder formulations divided into powders general purpose(such as ABSE, VSE) and special-purpose powders (which, as a rule, extinguish not only class D fires, but also fires of other classes).

2. Water:

The most common fire extinguishing agent. Its fire extinguishing properties lie mainly in its ability to cool a burning object and reduce the temperature of the flame. Being applied to the combustion source from above, the unevaporated part of the water wets and cools the surface of the burning object and, flowing down, makes it difficult for the remaining parts not engulfed in fire to ignite.

Water is electrically conductive, so it cannot be used to extinguish live networks and installations. If water gets on electrical wires may arise short circuit. Having detected a fire in the electrical network, you must first turn off the power to the electrical wiring in the apartment, and then turn off the general switch (automatic) on the input panel. After this, they begin to eliminate the sources of combustion using a fire extinguisher, water, and sand.

It is prohibited to extinguish burning gasoline, kerosene, oils and other flammable and combustible liquids with water in a residential building, garage or barn. These liquids, being lighter than water, float to its surface and continue to burn, increasing the combustion area as the water spreads. Therefore, to extinguish them, in addition to fire extinguishers, you should use sand, earth, soda, and also use thick fabrics, woolen blankets, coats moistened with water.

3. Sand and earth:

They are used to extinguish small fires, including spills of flammable liquids (kerosene, gasoline, oils, resins, etc.). When using sand (earth) for extinguishing, you need to bring it in a bucket or on a shovel to the burning site. When pouring sand mainly along the outer edge of the burning zone, try to surround the burning area with sand, preventing further spreading of the liquid. Then, using a shovel, you need to cover the burning surface with a layer of sand, which will absorb the liquid. After the fire has been knocked down from the burning liquid, you must immediately begin to extinguish the burning surrounding objects. As a last resort, instead of a shovel or scoop, you can use a piece of plywood, a baking sheet, a frying pan, or a ladle to carry the sand.

4. Fire shield:

To place primary fire extinguishing equipment in buildings and premises, special shields are installed. Fire extinguishers, crowbars, hooks, axes, and buckets are placed on the shields. Next to the shield there is a box with sand and shovels, as well as a barrel of water.

5. Nightmare:

Designed to isolate the combustion source from air access. This method is very effective, but is used only with a small fire.

Felt, asbestos sheet, etc. are also used, but cannot be used to extinguish fires. synthetic fabrics, which easily melt and decompose when exposed to fire, releasing toxic gases. The decomposition products of synthetics are usually themselves flammable, toxic and capable of sudden outbreaks.

6. Internal fire hydrant:

Designed for extinguishing fires of substances and materials with water. Can be used to extinguish anything for which water is used as an extinguishing agent.

The fire hydrant is placed in a special cabinet and equipped with a barrel and a hose connected to the hydrant. If a fire occurs, you need to break the seal or remove the key from its storage location on the cabinet door, open the door, roll out the fire hose, and then connect the barrel, hose and tap, if this has not been done, but it must be done! Then, turn the tap valve as far as possible, let water flow into the hose and begin extinguishing the fire. When putting a fire hydrant into operation, it is recommended that two people work together. While one person starts the water, the second brings the fire hose with the barrel to the burning site.

It is not recommended to install electric heating devices near flammable objects. It is prohibited to overload the electrical network or leave switched on electrical appliances unattended; when repairing the latter, they should be disconnected from the network.

The most fire and explosive household appliances are televisions, gas stoves, water heating tanks and others. Their operation must be carried out in strict accordance with the requirements of the instructions and manuals.

If you smell gas, you must immediately turn off the gas supply and ventilate the room; At the same time, it is strictly forbidden to turn on the lights, smoke, light matches or candles. To avoid gas poisoning, all people not involved in eliminating the malfunction should be removed from the premises. gas stove and gas pipeline.

You must not leave young children unattended, do not allow them to play with matches, turn on electric heaters or light gas.

It is prohibited to block access roads to buildings, approaches to fire hydrants, and lock the doors of common hallways in apartment buildings, force heavy objects into easily broken partitions and balcony hatches, close openings air zone smoke-free stairwells. It is necessary to monitor the serviceability of funds fire automatics and maintain fire detectors, smoke exhaust systems and fire extinguishing equipment in good condition.

· Actions in case of fire.

In the event of a fire, you must immediately leave the building using the main and emergency (fire) exits or stairs (using elevators is dangerous), and call the fire department as quickly as possible, inform your full name, address and what is burning.

In the initial stage of fire development, you can try to extinguish it using all available fire extinguishing means(fire extinguishers, internal fire hydrants, blankets, sand, water, etc.). It must be remembered that fire on electrical supply elements cannot be extinguished with water. First you need to turn off the voltage or cut the wire with an ax and a dry wooden handle. If all efforts were in vain and the fire spread, you need to urgently leave the building (evacuate). If the stairwells become smoky, you should tightly close the doors leading to them, and if a dangerous concentration of smoke forms and the temperature in the room (room) rises, move to the balcony, taking with you a soaked blanket (carpet, other dense fabric) to shelter from the fire in in case of its penetration through door and window openings; Close the door tightly behind you. Evacuation should continue along the fire escape or through another apartment, if there is no fire, using tightly tied sheets, curtains, ropes or a fire hose. You have to go down one at a time, protecting each other. Such self-rescue involves a risk to life and is permissible only when there is no other way out. You cannot jump from windows (from balconies) upper floors buildings, as statistics show that this results in death or serious injury.

When rescuing victims from a burning building, before entering it, cover your head with a wet blanket (coat, raincoat, piece of thick fabric). Open the door to a smoky room carefully to avoid a flash of flame from the rapid influx of fresh air. In a very smoky room, crawl or crouch and breathe through a damp cloth. If the victim's clothing catches fire, throw some kind of blanket (coat, raincoat) over him and press tightly to stop the flow of air. When rescuing victims, take precautions against possible collapse, collapse and other hazards. After removing the victim, give him first aid medical care and send to the nearest medical center.

For rapid response, mobile phones are being created brigades fire department .

Protection directly from fire is divided into human protection from high temperature , and, what is often more dangerous - dangerous factors in fire, one of which is carbon monoxide. Use thermal insulating clothing BOP(firefighter's combat clothing), insulating gas masks and compressed air devices, air-filtering hoods similar to gas masks.

The most important means of protecting humans from hazardous factors fire are planning solutions for buildings. Escape routes must be illuminated through openings in external enclosing structures. Glazing in these openings must be made of easily removable materials. On stairs that do not have natural light, air supply to the staircase must be provided. In case long corridors Without natural light, it is necessary to organize smoke removal from escape routes. Smoke removal and air pressurization systems must be activated by the fire alarm system.

Fireproof safes are used to protect valuables and documents from fire.

Fire extinguishing agents and rules for their use.

Fire is merciless, but people who are prepared for this natural disaster, having even basic fire extinguishing means at hand, emerge victorious in the fight against it.

Fire extinguishing agents are divided into henchmen(sand, water, blanket, blanket, etc.) and time sheets(fire extinguisher, axe, hook, bucket). Let's look at the most common fire extinguishers, and also give the basic rules for handling and using them when extinguishing fires.

Fire extinguishers- technical devices, designed to extinguish fires at the initial stage of their occurrence.

Foam fire extinguishers. Designed to extinguish fires with fire extinguishing foams: chemical (OCP fire extinguishers) or air-mechanical (OVP fire extinguishers). They are not used when extinguishing various substances and materials that burn without air access, and electrical installations under voltage.

To activate an OHP fire extinguisher, you must: bring the fire extinguisher to the source of the fire; lift the handle and throw it to the fullest; turn the fire extinguisher upside down and shake it; direct the jet to the source of fire.

To the disadvantages foam fire extinguishers include a narrow temperature range of application (from + 5 to + 45 o C), high corrosiveness of the charge; possibility of damage to the extinguishing object, the need for annual recharging.

To effectively extinguish a fire, it is important to know what the primary fire extinguishing agents are. Their purpose is to extinguish fire - initial stage fire, when there are still no factors dangerous to life and health in the form of smoke, elevated temperature and lack of oxygen. But as soon as a real fire breaks out, their effectiveness decreases to almost zero.

If primary fire extinguishing agents are not used, the fire will develop into a fire.

Classification of primary fire extinguishing agents

All primary fire extinguishing agents are conventionally divided into 4 groups:

- Fire extinguishing agents.

- Fire extinguishing materials.

- Extinguishing equipment.

- Equipment for extinguishing.

Fire extinguishing agents include earth, sand, soda, table salt and water. The most accessible and inexpensive means of eliminating fire is water. It has been used throughout the existence of mankind. When water hits a flame, according to the law of thermodynamics, it cools it. When spreading, areas untouched by fire become wet, and therefore protected from burning. The resulting steam blocks the access of oxygen (a fire catalyst) to the flame. Big drawback this method fire extinguishing is the property of water to conduct electric current Therefore, it is prohibited to use it to extinguish burning electrical appliances. The same applies to eliminating the combustion of gasoline, oils and other petroleum products. By their nature, they are lighter than water, which means they quickly float to the surface and continue to burn.

Soda, earth and table salt are used to extinguish fires at home, when there is not always a fire extinguisher nearby. When scattered onto the flame, particles of these substances block the access of oxygen and contribute to extinction. With their help, you can extinguish burning electrical equipment, since salt, earth and soda are not dielectrics. Baking soda helps fight oil fires in a frying pan.

Fire extinguishing materials include felt and asbestos fabric. The principle of their operation is also based on blocking the flow of oxygen to the combustion zone. Effective only with a small flame area. The use of primary fire extinguishing means involves covering the source of the flame with asbestos cloth or felt. If a person’s clothes are on fire, they can also be used to cover the body and wait until the burning stops. It is important to remember that during the development of a flame, toxic combustion products are released, therefore covering a person’s head with fire-extinguishing materials is prohibited.

Large enterprises must have a fire stand or shield on which extinguishing equipment is placed: a shovel, a crowbar, a hook, a hook, a bucket and other containers for water and sand, an ax, etc. The main purpose of the equipment is to deliver fire extinguishing agent to the burning zone and dismantle burning structures.

Extinguishing equipment is technical means, used to eliminate combustion. Before using them, you need to know their composition, operating principle and rules. There are only two primary fire extinguishing means belonging to the equipment group - a fire hydrant and fire extinguishers.

All fire hydrants located in special fire cabinets inside buildings are part of the internal fire-fighting water supply, consisting of a fire reservoir (reservoir), pumping station, fire trunks and fire hoses. This system is used both to extinguish fires and to fight fires (until the fire department arrives). IN modern houses The bathrooms have a small fire closet where the fire hydrant and hose are located. Placement of such a system in production and warehouses mandatory in accordance with fire safety standards. The number of fire hydrants is calculated based on the specifics of production, the area of the premises and the number of emergency exits.

As soon as the need for extinguishing arises, two people must go to the fire cabinet, remove the seal from the door, use the key (hidden behind the glass) to open it, and attach the hose to the tap. One person rolls out the sleeve and, holding it by the nozzle, gives a signal to the second to open the valve. The valve must be turned counterclockwise all the way to achieve maximum water pressure in the system.

It is important that the locations of such a system are well heated, since water can freeze at zero degrees Celsius.

- Staircases;

- Corridors;

- Evacuation routes (provided that the passage width is maintained at 1 m);

- Industrial workplaces with a high risk of fire.

The pressure in the system must correspond to a minimum mark of 1 MPa. The higher the building, the greater the water pressure must be provided. It is important to eliminate the possibility of water hammer when opening the tap, which can be dangerous for personnel involved in extinguishing the fire. The location of all fire cabinets at enterprises is reflected in the evacuation plans, which are familiarized to each employee during the introductory fire safety briefing.

According to Government Decree No. 390, every six months the internal fire water supply system must be checked for water loss using a hydraulic tester. This device consists of a 1 m long fire hose with a nozzle, ball valve and a pressure gauge. It is enough to connect this structure to a fire hydrant, open the valve all the way and close it after 15 seconds. The pressure gauge readings will indicate the water pressure in the internal fire water supply system. Also, every year all sleeves must be re-rolled onto a new roll. After each inspection, the cabinet must be sealed to prevent theft of fire extinguishing agents.

Types of fire extinguishers and methods of application

Fire extinguishers are second in popularity around the world after water. This hand-held devices, based on the principle of releasing (spraying) fire extinguishing agents onto the combustion site. Such primary fire extinguishing agents also have their own classification.

According to the volume of the cylinder, a fire extinguisher can be:

- Manual (weight of fire extinguishing agent up to 5 kg).

- Industrial (with a volume from 5 to 10 l).

- Mobile (more than 10 l).

According to the principle of fire extinguishing agent release:

- Own pressure of the contents.

- The pressure of the gas additionally pumped into the cylinder.

- The pressure of the gas formed during the interaction of substances inside the cylinder.

By content:

- Mermen.

- Carbon dioxide.

- Air-foam.

- Powder.

Fire safety standards oblige every facility where there is a threat of fire to have such primary fire extinguishing means.

Water fire extinguishers are used exclusively for extinguishing solid substances. This type of fire extinguishing agent is considered the safest for humans, but its effectiveness in combating burning metals, liquid substances and electrical appliances is low. Externally, it is a red cylinder with a locking and starting device in the form of a pistol, inside it there is water with special additives for ¾ of the volume of the cylinder, the rest of the space is filled with gas (usually just air). To activate it, you need to break the seal, pull out the pin and, pointing the hose with the socket at the source of the flame, press the lever. Allows you to stay no more than 1.5 m from the fire.

There are both manual and mobile. They have their own peculiarity - this is its content. A liquefied liquid is pumped inside the cylinder carbon dioxide, the pressure of which is high compared to other types of fire extinguishers, so the walls of such a fire extinguishing agent are twice as thick as conventional ones. Its launch is similar to the previous example, but it also has its own nuances. When you press the lever inside the cylinder, it starts chemical reaction. Liquefied carbon dioxide moves at speeds of up to 5 m per second, turning into snow. At the same time, the fire extinguisher socket, like the shut-off and starting device tube, is cooled to a temperature of 72 degrees Celsius! Therefore, holding them while starting the fire extinguisher is prohibited! When carbon dioxide hits a flame, it blocks oxygen from reaching the flame, turning into a gaseous cloud that dissipates after a few seconds.

PRIMARY FIRE FIGHTING MEANS.

They are designed to extinguish small initial fires of various substances and materials. Such means include internal fire hydrants, fire extinguishers (foam, carbon dioxide, powder, etc.), sand and fabric blankets.

Internal fire hydrants installed in buildings for various purposes. They are usually located at the entrance to stairwells and other accessible places in special cabinets. The index on the door of the fire hydrant cabinet is “PC”. Fire hydrant cabinets must be sealed. Fire hoses stored in cabinets must be dried, well rolled, and attached to taps and trunks.

To apply a stream of water from a fire hydrant, you need to open the cabinet door, take the barrel, roll out the hose towards the fire location and open the hydrant valve.

The fire hose is laid along the shortest route and distributed so that it does not have creases at the bends.

The stream of water must be directed to the place of the most intense combustion. From time to time you should change the direction of the jet depending on the spread of the fire or direct the jet to the upper part of the flame, since this achieves an extinguishing effect.

It is prohibited to nail the doors of fire hydrant cabinets, lock them, or use heavy-gauge metal wire for sealing, as this may delay the use of the internal fire water supply, or store foreign objects in the fire hydrant cabinets.

At least once a year, it is necessary to check the operation of internal fire hydrants (starting water).

Primary fire extinguishing means are located near the places where they are most likely to be used, in plain sight, and with easy access to them.

Fire extinguishers must always be in good condition, suspended or installed in a vertical position no higher than 1.5 m from the floor level, away from heating devices and other heat sources.

Canopies are installed over fire extinguishers located in the open air.

At temperatures below +1°C, fire extinguishers (type OHP-10, OVP-10) should be stored in a heated room.

When receiving and handing over a shift, service personnel of departments check the availability and serviceability of fire-fighting equipment using the inventory.

The movement of firefighting equipment and equipment from one room to another within a building and structure is permitted only with notification of the head of the department in agreement with the fire department.

The use of primary fire extinguishing agents for purposes other than their intended purpose is strictly prohibited.

Lists of assigned firefighting equipment and equipment are posted in all premises.

Write-off of primary fire extinguishing equipment that has become unusable is carried out on a general basis in agreement with the fire department.

The choice of type and calculation of the required number of fire extinguishers should be made depending on their fire extinguishing ability, maximum area, climatic conditions, fire class of flammable substances and materials in the protected area:

class A – solids mainly of organic origin (wood, textiles, paper, etc.);

class B – gas liquids, flammable liquids and melting solids;

class C – gases;

class D – metals and their alloys;

class E - associated with the combustion of electrical installations.

Each fire extinguisher in operation is assigned a serial number, which is applied to the body with white paint and a passport is issued in the established form. The passport indicates:

Serial number;

Manufacturer's name;

Time of acquisition;

Date of first charge and type of charge;

Dates of all subsequent fire extinguisher recharges;

Dates and results of all major inspections and hydraulic pressure tests;

Recharging and repairs are carried out in specialized organizations at charging stations.

Classification of fire extinguishers

Fire extinguishers are divided into:

Aquatic - OM;

Powder - OP;

Air foam - ORP;

Gas: – carbon dioxide – OU;

Freon - OX.

Air-foam fire extinguishers according to the brevity of the foam are divided into:

Low multiplicity – H from 5 to 20;

Medium multiplicity – C from 20 to 200.

Based on the principle of displacing OTV fire extinguishers are divided into:

Downloads – “3”;

With a compressed gas cylinder – “b”;

With a gas generating device – “G”;

With an ejecting device – “F”;

With thermal elements – “T”.

If possible, recharge fire extinguishers are divided into:

Rechargeable;

Not rechargeable.

Depending on the type of fire extinguisher being charged, fire extinguishers can be used to extinguish fires of one or more of the following classes of flammable substance fires:

Solid – “A”;

Liquid – “B”;

Gaseous – “C”;

Electrical equipment, energized - “E”.

OP-5 3 – ZA, 89V, S-01, T2- GOST – powder fire extinguisher (OP),

capacity – 5 l, injection (3); for extinguishing - solid flammable substances (fireplace rank -ZA), liquid flammable substances (89B) and gas (C); model 01, climate version T2.

Design and principle of operation of fire extinguishers.

Fire extinguisher OHP-10 (chemical foam).

Purpose.

Designed to extinguish small fires of solid (A) and liquid (B) flammable substances, at an ambient temperature not lower than +5°C. Do not use to extinguish fires in live electrical installations. Charged fire extinguishers must be stored in an upright position (valve side up).

Technical characteristics:

The useful capacity of the cylinder is 8.7 l;

Foam capacity – at least 45 l;

Action time – about 60 s;

Jet length – at least 6 m;

Charge weight – about 4.6 kg;

Weight of fire extinguisher with charge – 14 kg;

Working pressure in the housing – 1.4 MPa;

Foam shortness – 5.

The fire extinguisher charge consists of an alkaline and an acid part. The alkaline part consists of an aqueous solution of sodium bicarbonate and licorice extract, the acidic part consists of a solution of iron sulfide and sulfuric acid.

Device and principle of operation.

The fire extinguisher consists of a welded cylindrical cylinder with upper and lower bottoms, neck and side handle welded to it. A cap with a valve device is screwed onto the neck, which is designed to close the neck of the acid glass using a handle and a rubber valve on the rod. A spray with a hole is pressed into the neck, which is closed with a safety membrane made of parchment. The acid glass is made of polyethylene.

The principle of operation of the fire extinguisher is based on the use of the fire extinguishing properties of the foam formed as a result of a chemical reaction when mixing the alkaline and acidic parts of the fire extinguisher charge.

As a result of the reaction, carbon dioxide is formed, which creates pressure in the cylinder at which the membrane ruptures and the foam is ejected through the spray in the form of a jet.

Bring to the place of fire;

Clean the spray with a needle;

Turn the handle located on the lid up 180° until it stops;

Turn the fire extinguisher upside down (shaking at the beginning of the action increases its effectiveness). The fire extinguisher does not require any blows to activate.

When extinguishing burning solid materials, direct a stream of foam to the place of greatest combustion, knocking down the flame from below. When extinguishing flammable liquids poured into open vessels, the foam stream should be directed to the inside side of the vessel. When extinguishing liquids spilled on a surface, cover the burning surface with foam.

When working with a fire extinguisher, it is necessary to prevent chemical foam from getting on open areas human skin and clothing. If this happens, you need to wash off the foam with plenty of water and change clothes.

The chargeability of foam fire extinguishers is designed for 1 year, after which they must be recharged. The volume of the OTV charge may be less than the nominal value within 5%. Recharging is carried out at specialized stations.

Fire extinguisher OVP-10 (air-foam).

Purpose.

Designed to extinguish small fires of solid (A) and liquid (B) flammable substances and smoldering materials at temperatures environment not lower than +5°С.

Do not use to extinguish fires in live electrical installations.

Technical characteristics:

Fire extinguishing agent – 6% aqueous solution of foaming agent;

Foam ratio – from 50 to 70;

Capacity – 10 l;

Volume of solution – 9 l;

Jet length – from 4 to 5 m;

The maximum operating pressure in the housing is 1.2 MPa;

Gas cylinder capacity – 0.175 l;

Fire extinguisher weight: with charge – no more than 15.5 kg; without charge – 5.8 kg.

Device and principle of operation.

The fire extinguisher consists of a welded cylindrical cylinder, a siphon tube, a cylinder with carbon dioxide, a membrane, a handle, a lid, a neck, a start button, a cotter pin, a safety pin, a hose, and a foam generator.

The principle of operation is based on the displacement of the foaming agent solution by excess pressure of the working gas (air, nitrogen, carbon dioxide). When the shut-off and starting device is activated, the plug of the cylinder with the working gas is pierced. The foaming agent is forced out by gas pressure through the siphon tube into the nozzle. In the nozzle, the foaming agent is mixed with the suction air, resulting in the formation of foam.

Rules of application, safety measures.

Remove the fire extinguisher from the bracket;

Bring it to the fireplace,

Remove the safety ring (pull out the pin);

Point the foam generator at the source of fire;

Hit the shutter button.

If the foam solution gets on exposed skin, rinse with plenty of water.

Fire extinguishers OU-2, OU-5 (carbon dioxide).

Purpose.

OU fire extinguishers (carbon dioxide) with a cylinder capacity of 2, 3, 5 and 8 liters; designed to extinguish fires of substances whose combustion cannot occur without air access; electrical installations under voltage of no more than 10 kV; in temperate climates in the operating temperature range from –40°С to +50°С.

It is prohibited to use substances that can burn without air access (aluminum, magnesium and their alloys, sodium, potassium) for extinguishing.

Technical characteristics

|

Name of parameters |

||||

|

1. Case capacity (according to the manufacturer’s documentation), l |

||||

|

2. Operating pressure in the fire extinguisher body at t=20°C, |

||||

|

3. Duration of supply of fire extinguishing agent, minimum at t=20°C, s of agent. |

||||

|

4. Minimum fire extinguishing jet length at t=(20±5) °C, m |

||||

|

5. Mass of fire extinguishing agent, kg |

||||

|

6. Fire extinguishing capacity for extinguishing a model fire according to class “B”, m 2 |

||||

|

7. Fire extinguisher weight (for manual fire extinguishers without bracket), total, kg, no more |

||||

|

8. Length of hose with socket, m, not less |

||||

|

9. Duration of putting the fire extinguisher into action, s, no more |

||||

|

10. Service life, years, not less |

Device and principle of operation.

The manual fire extinguisher is an individual thick-walled steel cylinder. A locking device is screwed into the neck, which has a safety device, a handle, a snow-forming bell and a siphon tube.

The principle of operation is based on the displacement of a charge of carbon dioxide by an excess pressure of 5.8 mPa. When the shut-off and release device is opened, carbon dioxide flows through the siphon tube to the socket and changes from a liquefied state to a solid (snow-like) state. The temperature drops sharply to minus 70°C. Carbon dioxide, falling on a burning substance, isolates it from air oxygen and cools it.

Rules of application, safety measures.

To activate the fire extinguisher:

Remove the fire extinguisher from the holder and bring it to the fire as close as possible, but not closer than 2 m;

Point the bell at the hearth, pull out the pin and press the lever.

When releasing the charge from the socket, be careful, i.e. Do not touch the bell with bare hands, as the temperature on its surface drops to – 60 – 70°C. When extinguishing live electrical installations, it is not allowed to bring the socket closer than 1 m from live parts and flames.

After using a fire extinguisher in a closed area, it is necessary to ventilate it.

During transportation and storage, do not allow:

Direct heating by sunlight or other heat sources above +50°C;

Moisture getting into the locking head or socket;

Strikes to the head and balloon.

Do not store or operate fire extinguishers without the receipt and seal of the manufacturer or the organization recharging them.

Recharge and repair of the fire extinguisher should be carried out in specialized organizations.

Control weighing should be carried out at least once a year. The amount of leakage should not exceed 5% or 50 g (the lesser of these values per year). The mass of the cylinder with the shut-off and release head is stamped on the body of the shut-off device. The total mass of the fire extinguisher is determined by adding to it the mass of CO2 indicated on the label and in the passport.

Fire extinguishers OP-2, OP-5, OP-50 (powder).

OP (powder) fire extinguishers are designed to extinguish fires of solid flammable substances (class A), flammable liquids or melting solids (class B), gaseous substances (class C), as well as fires in electrical installations energized by no more than 1000 V, at operation in temperate climates in the temperature range from –40° to +50°С.

Fire extinguishers are not intended to extinguish fires of alkali and alkaline earth metals and other materials, the combustion of which can occur without air access.

Technical characteristics.

|

Name of indicators |

|||||

|

Capacity of the fire extinguisher body, l, not less |

|||||

|

Powder charge mass, |

|||||

|

Working pressure in the fire extinguisher body, mPa (kgf/cm2) |

|||||

|

Powder jet length, |

|||||

|

Fire extinguisher activation time |

|||||

|

Powder release time |

|||||

|

Number of operations during intermittent powder supply, |

|||||

|

Average term fire extinguisher service, l |

|||||

|

Time between technical maintenance |

Once a year |

||||

Device and principle of operation.

The OP fire extinguisher consists of:

- downloads (3)– a durable steel case containing pressurized fire extinguishing powder, a pressure gauge, a starting-locking device, a handle with a pin and a seal, a hose with a tip;

- with compressed gas cylinder– a durable steel case containing the powder, a locking device with a striker and a pin, a can of compressed gas and a siphon tube, flexible hose with a lever nozzle (nozzle).

The principle of operation is based on the displacement of fire extinguishing powder from the fire extinguisher body by excess pressure; compressed gas pumped directly into the housing (3) or located in the cylinder (B) when opening the shut-off device or piercing the cylinder membrane, through a siphon tube, hose or nozzle. The powder, falling on the burning substance, isolates it from air oxygen.

Rules of application, safety measures .

To activate the fire extinguisher:

- downloads (3)– remove the fire extinguisher from the holder and bring it or bring it to the fire ( minimum distance– 3 m), break the seal, pull out the pin, direct the hose with the nozzle onto the fire and press the lever;

- with compressed gas cylinder (B)– remove from the holder, bring it to the fire (minimum distance - 3 m), break the seal, pull out the pin, hit the striker, point the hose with the nozzle at the fire and pull the trigger of the nozzle.

When extinguishing electrical installations that are under voltage, it is not allowed to bring the nozzle (nozzle) closer than 1 m to the electrical installation and the flame. Do not operate or store a fire extinguisher without the receipt and seal of the manufacturer or the organization recharging it. Check the working gas in fire extinguishers (3) at least once a year. Check visually using the indicator. The indicator arrow should be in the green sector. The condition of the fire extinguishing powder is checked after 5 years.

Asbestos blankets

used to localize small fires.

When using them, the sunbathing area is directly covered. Asbestos blankets should be kept in pencil cases marked with the word “feather.”

The sand is in boxes equipped with a shovel. Used to extinguish small fires. The extinguishing method is to separate the flame and reduce the temperature of the fire.