A water-filled sprinkler system is an automatic water fire extinguishing system completely filled with water or an aqueous solution, designed to protect heated objects. Such systems are used in most facilities that require protection with a fire sprinkler system.

Each section of the sprinkler installation must have an independent control unit. When protecting several rooms or floors of a building with one sprinkler section, to issue a signal specifying the address of the fire, as well as to turn on warning and smoke removal systems, it is allowed to install liquid flow alarms on supply pipelines, excluding ring ones.

Sprinkler sprinklers for water-filled AUPs are installed vertically with rosettes up or down or horizontally, in air-filled AUPs - vertically with rosettes up or horizontally.

It is allowed to connect internal fire hydrants to the supply pipelines of water-filled sprinkler AUPs with a diameter of 65 mm or more. fire-fighting water supply. The operating time of internal fire hydrants equipped with manual water fire nozzles and connected to the supply pipelines of the sprinkler installation should be taken equal to the operating time of the sprinkler installation.

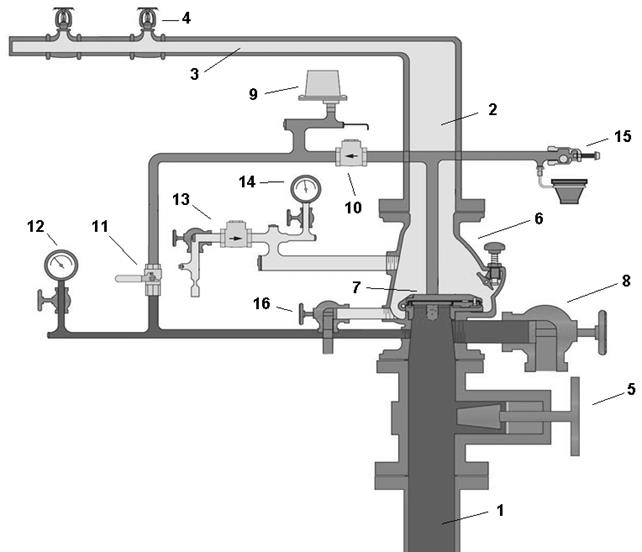

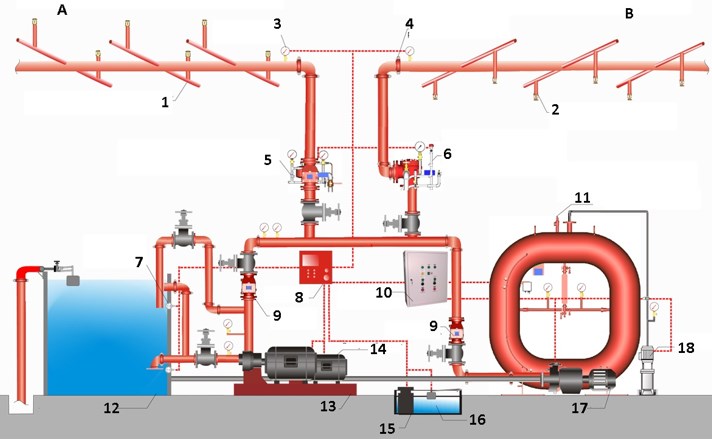

Water-filled sprinkler control unit(UU) (Fig. 3.11) is designed to work in water and foam fire extinguishing sprinkler installations, supplies fire extinguishing liquid, issues a signal to generate a command impulse to control the elements fire automatics(pumps, warning system, turning off fans and technological equipment etc.), and also monitors the condition and checks the performance of these installations during operation.

Fig.3.11. Appearance sprinkler water-filled unit

Hydraulic circuit sprinkler water-filled unit is shown in Fig. 3.12. The sprinkler signal valve (1) is the main element of the water-filled sprinkler system. Valve is a normally closed shut-off device designed to release a fire extinguishing agent when a sprinkler is activated and issue a control hydraulic pulse. The check valve (2) prevents the release of pressure in the supply pipeline when it decreases in the supply pipeline.

Fig.3.12. Hydraulic diagram of a water-filled sprinkler unit

Two three-way valves (3) are designed to turn off pressure gauges when maintenance and verification. Two pressure alarms (4) are designed to issue a signal when the control unit is triggered. The pressure gauge (5) is designed to monitor the pressure in the supply pipeline. The pressure gauge (6) is designed to monitor the pressure in the supply pipeline. The valve (7) is intended for monitoring (checking) pressure alarms during maintenance. The valve (8) is designed to drain liquid into the drain from the valve and distribution pipeline (closed in standby mode). The valve (9) is designed to close and open the signal hole when installing the control unit in standby mode. The delay chamber (10) is installed on the line of pressure alarms and is designed to minimize the likelihood of issuing false signals caused by sudden fluctuations in the pressure of the water supply source. The drain tube (11) is designed to drain liquid into the drain from the signal hole; it has a narrowing (17) with a diameter of 3 mm. The drain tube (12) is designed to discharge air from the delay chamber; it has a narrowing (17) with a diameter of 3 mm. The filter (13) is designed to protect the working parts of the valve and piping from clogging with foreign objects in standby mode.

When the sprinkler is activated, the pressure in the supply pipeline and in the cavity above the valve (14) decreases, the liquid under overpressure in the inlet cavity of the valve, the valve opens, the liquid begins to move through the distribution pipeline to the sprinkler, and the annular groove (15) of the seat, the liquid enters the signal hole (16) and flows through the pipeline into the drain. Along the path of liquid drainage in the pipeline there is a narrowing (17) (3 mm in diameter), which creates additional resistance to the liquid and provides the necessary pressure for the pressure alarms (4) to operate. Pressure alarms issue signals to control the pump and to the central monitoring panel, the control unit goes into operating mode.

Install the control unit into standby mode in the following sequence:

Close all controls (taps);

Open the valve (18) to fill the system with fire extinguishing liquid and create pressure in the valve and distribution pipeline;

Open the tap (9) (after filling the system with liquid and creating pressure in the valve), allow the accumulated water to drain from the signal line and from the delay chamber. There should not be a constant leak of liquid in standby mode.

Carry out a manual test start:

Open the tap (8), when the pressure drops, the valve shutter should open, and the pressure alarms (4) should give a signal that the valve is activated. Set the control unit to standby mode.

Air sprinkler system is a water-air automatic fire extinguishing system (Fig. 3.13), designed for unheated premises(protected objects where low temperatures are possible).

The system is built taking into account the following:

The supply pipeline (1) is filled with water or an aqueous solution, the supply pipeline (2) and distribution pipeline (3) are filled with compressed air or nitrogen.

Sprinklers (4) are installed only with the rosette facing up.

The pumping station must be located in a heated room.

Elements of the pumping station, in addition to standard elements, are:

Compressor;

Equipment for monitoring and maintaining air pressure.

Air sprinkler systems, as a rule, protect unheated warehouses, hangars, parking lots, individual premises of enterprises, etc.

Rice. 3.13. Air sprinkler control unit

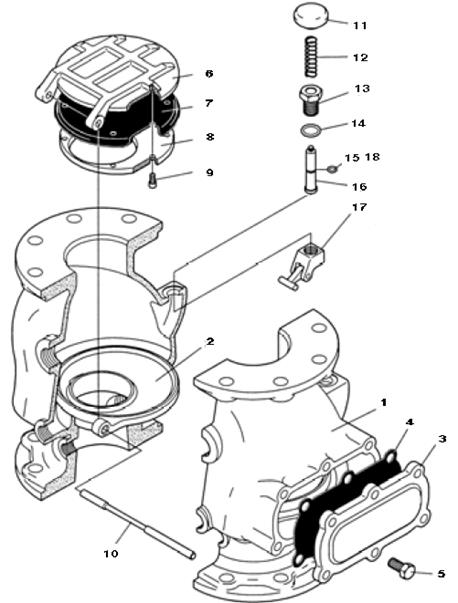

The sprinkler air control unit includes a sprinkler air valve (6) with a damper (7), a gate valve (5), a main drain valve (8), a universal pressure switch (9), a check valve (10), a testing valve (11) designed to check the SDS, a pressure gauge (12) is designed to control the pressure in the supply pipeline, a system for connecting the air supply (13), an automatic drain valve (15), a pressure gauge (14) is designed to control the air pressure, a lower drain valve (16).

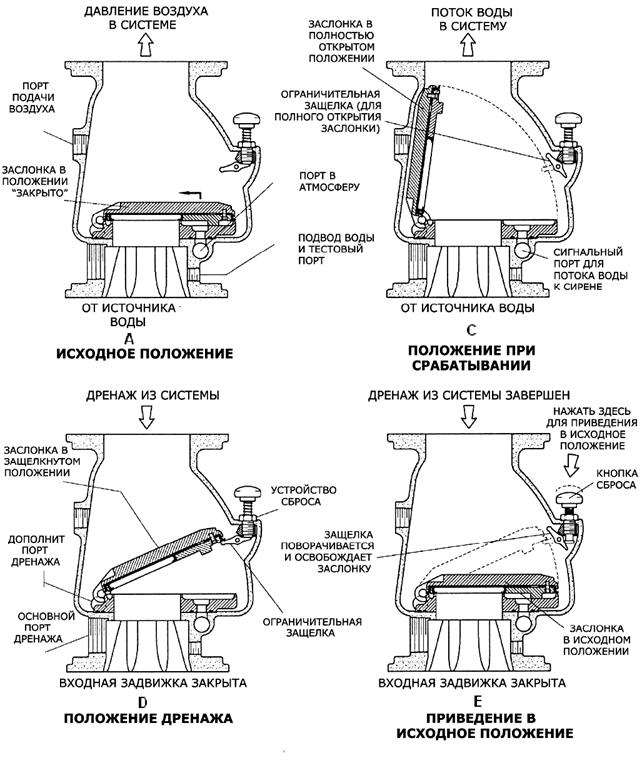

The air valve is a differential type device in which, to maintain the valve in its original state, a significantly lower air (nitrogen) pressure in the system is required than the water inlet pressure.

The essence of valve differential is based on the unequal pressure areas on the valve from the air side and from the water side, combined with the difference in distances from the valve axis to the center of the water seal and from the valve axis to the center of the air seal. In this case, the air pressure of 1 psi (0.07 bar) balances the water pressure of 5.5 psi (0.38 bar).

The minimum required air (nitrogen) pressure in the system is given in Table 3.3.

Table 3.3

Functional dependence of the required air pressure

in the system from water pressure

From the data presented it follows that the air pressure is approximately 18% of the static water pressure at the inlet plus the required pressure margin of 1.4 bar, necessary to prevent false alarms caused by fluctuations in the inlet water pressure.

Rice. 3.14 Composition of a spindle air valve: 1 - valve body; 2 - valve seat; 3 - side cover; 4 - side cover gasket; 5- bolt with hex head; 6 – damper; 7 - damper gasket; 8 - damper gasket board; 9 - damper mounting bolt; 10 - valve flap axis; 11 - reset button; 12 - reset spring; 13 - reset bushing; 14 - reset bushing ring; 15 - reset plunger ring; 16 - reset plunger; 17 - reset latch.

The composition of the spindle air valve is shown in Fig. 3.14. Valve condition in various modes shown in Fig. 3.15 The intermediate valve chamber, located between the air and water seals, is under atmospheric pressure through the signal port connection and the normally open automatic drain valve trim. The connection between the intermediate chamber and the atmosphere is important aspect valve operation. Otherwise, the system air pressure applied to the top of the damper would not be sufficient to hold the valve closed. For example, if the air pressure in the system is 2.7 bar, and the residual pressure in the intermediate chamber is 1.7 bar, then the resulting pressure on the damper from above will be only 1.0 bar. This pressure is not enough to keep the valve closed against the 6.9 bar pressure from the water source on the valve below. This is why the automatic drain valve stem must be pressed out several times during the valve reset procedure or during test runs, which ensures that it remains open.

When one or more sprinklers are opened, the air pressure in the system drops due to air leakage through the open sprinklers. If the air pressure decreases sufficiently, the water pressure will exceed the differential holding the damper closed and open the damper slightly, as shown in Fig. 3.15 (C). The water flow enters the distribution pipeline and is sprayed through open sprinklers. In addition, when the valve is open, the intermediate chamber is under pressure and the flow of water through the signal port of the valve activates the alarm system. On the other hand, the amount of water flow through the signal port is sufficient to close the normally open automatic drain valve.

After the valve is activated and the valve at the system inlet is subsequently closed to stop the flow of water, the valve valve will be locked in the open position, as shown in Fig. 3.15 (D). Fixing it open will allow complete drainage of the system through the main drain port.

Rice. 3.15. Air sprinkler valve condition

in various modes

Once the system is drained and the system is being reset, the external reset button can be easily pressed and the valve will be released from the latch, as shown in Fig. 3.15 (E). This way the air sprinkler system will be installed to its original condition without removing the side cover.

Sprinkler and deluge fire extinguishing equipment - the most common options automatic systems.

They are similar in many ways, but the significant difference between them lies in the design of the final sprinklers. Also, both versions are used in different conditions and at facilities for various purposes.

Application area

Sprinkler and deluge automatic fire extinguishing allows you to control objects of different sizes (industrial or civil) with different areas and eliminate fires before the fire spreads and causes significant damage.

With the help of such installations, it is quite possible to organize a fire extinguishing system in areas where it is not possible to use fire-fighting equipment.

In addition, these solutions allow you to keep under control facilities where personnel are permanently or temporarily absent. In this case fire protection installation when changing parameter values environment in the serviced area eliminates the source of fire as quickly as possible.

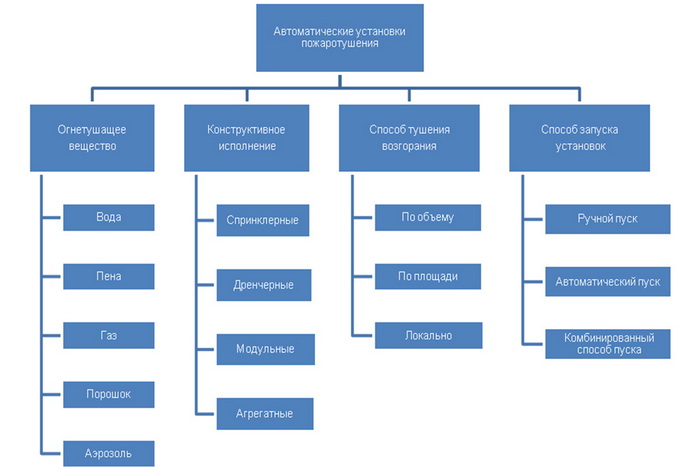

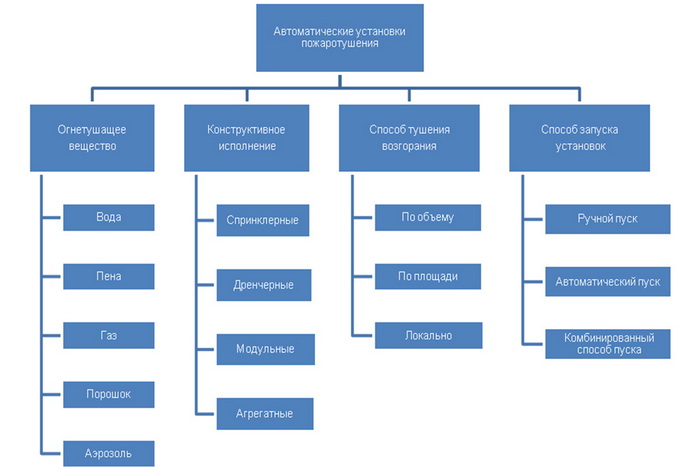

Types of automatic fire extinguishing systems

Such equipment is classified according to the type of fire extinguishing agent (fire extinguishing agent). There are:

Such equipment is classified according to the type of fire extinguishing agent (fire extinguishing agent). There are:

- Water installations;

- Powder;

- Gas;

- Foam;

- Aerosol.

Each type is used to ensure fire safety of objects for different purposes. One of the most popular is water systems. They exist in two versions: sprinkler and deluge installations automatic fire extinguishing. The first of these is used for the purpose of instant response in rooms with an increased risk of fire. The second option is usually used to extinguish a fire throughout the entire facility at once. In addition to this, it also allows you to irrigate vertical surfaces.

What are the advantages of a sprinkler system:

The sprinkler control unit exists in two versions: water and air. In the first case, there is always water in the pipeline, in the second case - compressed air. If upon occurrence dangerous situation water system will react instantly, then in the case of air system The water must first displace the compressed air. But the first of the named executions has significant drawback– this installation cannot be used in conditions low temperatures air, which is explained by the risk of freezing of the pipeline, which constantly contains water.

The deluge pipeline does not need to be kept filled with water. Such systems are put into operation after the fire alarm. And this is done either manually or through an automation unit. The option with sprinklers (the so-called sockets of a special kind, which are the exhaust elements of fire extinguishing agents) involves the use of special temperature-controlled flasks or thermal locks located in the sockets. If the temperature in the room or the pressure in the system fluctuates significantly, the release elements are triggered - the lock or lock melts.

Let's watch a video about the types of automatic fire extinguishing systems:

One of the main advantages that sprinkler and deluge fire protection systems have is that in both options water can act as an exhaust agent.

What are the differences between both options?

Despite the apparent similarity, these two settings have significant differences:

- Design features determine the intended use of these systems versions. Thus, the sprinkler contains a thermal lock or temperature-controlled flask inside. In any case, this element is subject to destruction when the values of environmental parameters fluctuate. This means that after one operation, the sprinklers will have to be replaced with completely new ones, since these devices cannot be disassembled. Drenchers (outlet elements of deluge systems) are an irrigation head open type, activated remotely or manually.

- Another difference follows from the first point - the intended purpose. Deluge and sprinkler automatic installations used for rapid response at sites different sizes. But the first of these are suitable for extinguishing a fire over the entire area of the serviced facility at once, and the sprinkler system, first of all, responds to changes in the environmental parameters of an area with a high risk of fire.

- Considering that the deluge installation can be in a state not filled with water, it can be used even at sites where the temperature is below +5 degrees. If we talk about sprinkler design, then depending on the type, there is also the possibility of use in more severe conditions. But the water version of the installation, which must always be filled, is used only at positive temperatures.

- The response speed of sprinklers is lower due to the fact that it takes some time to destroy the thermal lock or temperature-controlled bulb.

As you can see, the difference between a sprinkler and a deluge design is too obvious, and as a result, it is the difference in the structure of these elements that determines the intended purpose and operating principle of the two systems.

Reliability of systems, their cost

As already mentioned, since water is the most inexpensive fire extinguishing agent, deluge and sprinkler automatic fire extinguishing systems are the most affordable options. The cost of installations will depend on the size of the object, its intended purpose, etc. If you take a small plot, for example, 50 square meters. m, then to equip it with an automatic system with the installation of a fire-fighting pipeline you will need approximately 55,000 rubles. If the system requires optional equipment (pumping station), then the cost may increase to 150,000 rubles.

Prices for the purchase and installation of both versions are approximately the same. Much also depends on the company that provides installation services. The features of the object itself are also important. Drenchers and sprinklers are built into the pipeline, which is secured using special clamps equipped with a threaded rod. This mounting option makes it possible to install at any height.

A little about the Bastion system:

In terms of reliability, both installation options are, again, approximately equally good. This is due to quality structural elements. For example, the installation of sprinklers does not require the use of special seals, since threaded connection already equipped with sealant. But before deciding which system to give preference to, you should take into account the response speed of each of them. We must not forget about some of the operating costs that come with a sprinkler installation. We are talking about a small degree of inertia of such a system, because with temperature fluctuations it can work, even if there are no sources of fire.

Summarizing all that has been said, we can summarize that the use of both sprinkler and deluge installations is justified, especially when it comes to large facilities where there is no personnel for a certain period of time or permanently. This makes it possible to localize a fire at the initial stage, preventing it from spreading throughout the entire territory of the facility. The main advantage is the ability to avoid the possibility of causing irreparable damage to property and premises served by such installations.

The first fire sprinkler system, the operating principle of which is based on the destruction of heat-sensitive locks, was used at the end of the 19th century. At that time, the installations were a system of pipes in which water was constantly under pressure. The holes through which she could enter the room were closed with plugs of wax mixed with a solid filler. Naturally, they were imperfect and were activated when a fire was already raging in the room and the temperature was very high. The false positive rate was also very high.

Modern automatic fire sprinkler systems are much more efficient due to the use of additional detectors early detection sources of fire, but the principle of triggering through the destruction of a low-fusible lock on the spray nozzle remains unchanged.

Operating principle and sequence of fire extinguishing processes

Automatic sprinkler fire extinguishing systems (ASFS), regardless of the type, have a built-in sprinkler, which is equipped with a thermal lock bulb. Under the influence of the threshold temperature for which the substance in the flask is designed, it is destroyed and the pipeline supplying the fire extinguishing agent is depressurized.

After depressurization of the pipeline, the system performs the following actions:

- A signal is sent to turn on the jockey pump, which maintains the required pressure in the pipeline. The device automatically turns off after the fire pump is activated;

- Reporting a fire to the central security console;

- If the building has elevators, they are all called to the first floor and are blocked after opening the doors;

- , and signs indicating the direction of personnel evacuation are activated;

- The ventilation system is turned off and the air duct system of smoke-filled rooms is blocked by valves;

- The main fire pump starts;

- If necessary, the backup fire pump is started.

Sprinkler fire extinguishing is designed to eliminate local fires. In rooms where the temperature has not reached a critical point, the lock will not be destroyed and water will not be sprayed.

Universal automatic fire extinguishing sprinkler systems combine several systems:

- Fire alarm – notifies about a fire, provides information about the location of the fire, manages the evacuation of personnel,

- Control system - includes smoke protection and separate sections of the fire extinguishing system.

- Pump system – automatically maintains the required pressure, both during extinguishing and in standby mode.

Application area

According to the Decree of the Government of the Russian Federation No. 390 of April 25, 2012. "ABOUT fire mode", Federal Law No. 123-FZ dated July 22, 2008 " Technical regulations about the requirements fire safety» and many industry documents, installation of a fire extinguishing sprinkler system must be carried out at the following facilities:

- — Data centers, server rooms, data centers;

- Underground and above-ground parking lots, while above-ground ones must have more than 1 floor;

- Structures with a façade height of 30 m or more. Exceptions include residential buildings and industrial buildings that have the category fire danger D and G;

- Single-story structures consisting of metal structural elements with flammable insulation. Square public buildings of this type should be more than 800 m 2, and administrative and household - more than 1200 m 2.

- Buildings in which trading activities are carried out, with an area of the above-ground part of more than 3500 m 2 and the basement (basement) part of more than 200 m 2. Exceptions include buildings where trade and storage of non-combustible substances are carried out: metal, glass, porcelain, food.

- All buildings, regardless of area, where flammable or combustible liquids and materials are traded. The exceptions are retail packaged material in a package of no more than 20 liters.

- Exhibition halls and art galleries with an area of 1000m2.

- Cinemas, theaters, concert halls and other entertainment facilities with more than 800 seats.

- Warehouse buildings with shelving heights of more than 5.5 m.

Advantages and disadvantages

Splinker fire extinguishing has a number of significant advantages:

- Relative low cost of installation, installation and maintenance;

- High fire extinguishing efficiency;

- Possibility of installation in any type of room;

- Quick installation, which does not require changes in layout and radical violation of integrity load-bearing structures and partitions;

Flaws:

- Significant limitation of the temperature norm, sprinkler fire extinguishing does not function at negative temperatures;

In rooms with a minimum temperature of more than 5°C, it is practiced to use water-filled distribution and supply pipes. Where the temperature drops to -5°C, only filling the supply pipeline is allowed.

- A large amount of water used can cause damage to property located in the room;

- Sprinklers are actually disposable devices, and after they are activated, replacement is required to bring the system back into standby mode;

- The response time of the system can be delayed even if there is significant smoke in the room, since temperature is a key aspect.

The structure of the sprinkler installation and its main components

Diagram of the functioning of an automatic sprinkler water fire extinguishing system.

A. Water-filled supply pipeline;

B. Water-air supply pipeline;

- Sprinkler sprinklers SVV with rosette facing up;

- Sprinkler sprinklers with socket facing downwards;

- Fire extinguishing agent supply control sensor;

- Pipeline detachable couplings;

- Direct-flow water-filled sprinkler control unit;

- Sprinkler control unit based on SKD air valve;

- Device for monitoring the level of fire extinguishing liquid in the tank;

- Central device for monitoring and controlling the entire installation;

- Single disc rotary check valve;

- System control cabinet automatic maintenance pressure in the pipeline (water supply);

- Automatic water feeder;

- Tank with fire extinguishing agent;

- Main pump;

- Backup pump;

- Sump drain pump;

- Drainage pit;

- Water feeder filling pump;

- Compressor.

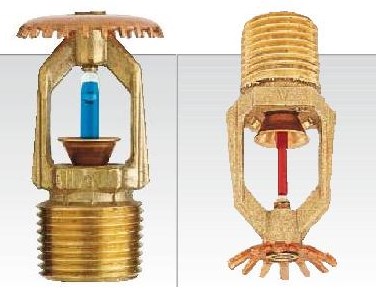

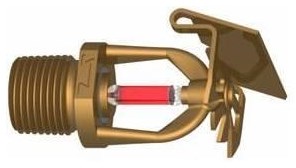

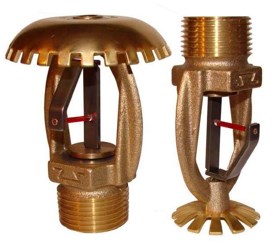

Sprinkler

The main working unit on which both the speed and efficiency of the entire fire extinguishing installation depends is the sprinkler. The main detail This device is a capsule with a heat-sensitive liquid. The response temperature is strictly defined; it ranges from 57 to 343°C. The melting point of a particular atomizer model can be easily determined by the color of the capsule.

Capsules with a melting point of 57°C and 68°C are considered low-temperature. The duration of their operation should not exceed 5 minutes from the moment the limit temperature occurs in the room. The best option is considered 2-3 minutes. For high-temperature capsules, the permissible value is up to 10 minutes.

Capsules with a melting point of 57°C and 68°C are considered low-temperature. The duration of their operation should not exceed 5 minutes from the moment the limit temperature occurs in the room. The best option is considered 2-3 minutes. For high-temperature capsules, the permissible value is up to 10 minutes.

Many sprinkler designs have been developed. The fire extinguishing sprinklers in the photo represent models designed to solve a specific range of problems:

Positioning – installation of the device with the socket up SVV and socket down SVN.

Directing the jet at a certain angle localizes the spray area to increase the effect. Used to create water curtains or cooling installations.

Sprinkler to create a fine flow. It is used to localize and extinguish class A fires. It is advisable to use it in rooms where a large amount of fire extinguishing liquid can damage material assets.

A device with increased performance. Used for early detection and suppression of the fire source. Recommended for use in high-rack warehouses with a height of up to 12.5 m, as well as for installation in rooms with a ceiling height of up to 20 m.

Installation of fire sprinkler system

To construct the system, pipes galvanized on the outside and inside are used; the use of seam-type pipes is allowed. The pipes are fastened to the ceiling using clamps with an elastic band in increments of 1.5 m. The pipes are connected to each other by welding or crimping using special fittings and pneumatic crimping tools. electric tools. At this stage, fire sprinklers are connected.

Installation of distribution units and a reservoir with fire extinguishing agent is carried out in a special, separate room, most often in the basement. The control unit is mounted in the same place, but with the backup system connected to the security console.

It should be noted that in most cases, sprinkler installation pipes are under pressure. Therefore, maximum attention should be paid to the quality of the connection of all elements.

2014-03-01 21 803One of the simplest, most ingenious and effective types of automatic fire extinguishing systems are fire sprinkler systems. The design is based on the use of final elements plumbing system, which are capable of opening independently when the room temperature reaches a certain threshold value.

The history of the emergence and use of sprinklers dates back to the beginning of the 19th century, and their widespread use in various modifications continues to this day. The effectiveness and survivability of such systems is determined by the fact that they lack complex elements feedback or automatic devices, based on semiconductor, computer or other circuits of increased complexity.

Everyone knows what simpler system, the more reliable it is. The principle of operation of the fire sprinkler system has not changed since its invention. Of course, new elements and materials are used, the efficiency of use is calculated more accurately, they become more powerful, the response inertia decreases, but the fundamental principles remain unchanged. This is the essence of all great inventions - they can only be improved, but it is very difficult to make fundamental changes.

Water sprinkler fire extinguishing, originally invented as a network of pipes constantly filled with water under a certain pressure. A system of tips, covered with caps made of a material that is easily destroyed when the temperature rises, is the main means of extinguishing. When a fire occurs in a room, they melt or collapse from the heat, and water from the pipes is sprayed onto the fire.

All subsequent improvements mainly concerned the design of the tips and their locking locks. The current state is described by the name itself - sprinkler. This is a sprinkler that sprays water under pressure.

Modern fire sprinkler system, what is it?

Fire extinguishing sprinkler systems currently in use differ from classic ones in many details that increase not only the efficiency and reliability of use, but also the period of their use. As at the beginning of the century, the main substance for extinguishing a fire is ordinary water from a city or local water supply. Its pressure in plastic or steel pipes is maintained at a constant level using a system check valves. In the event of a malfunction in the main water supply system or its temporary shutdown, the pressure in the sprinkler system is maintained at the required level for initial operation. System advantages:- Work in automatic mode;

- Lack of power supply;

- Absence complex circuits feedback;

- Constant readiness to work;

- Long service life.

The insert is located with outside to eliminate the cooling effect of water from the water pipeline, which can increase the inertia of the system.

Modern sprayers are designed to effective work within 12 m² of service area. In this case, one or more neighboring devices may operate, which do not lead to a significant drop in pressure in the system. This ensures the required duration of operation of the automatic fire extinguishing sprinkler system, which increases its efficiency. Disadvantages of the system:

- Response delay;

- Dependence on the operation of the water supply network;

- Contraindications for extinguishing electrical wiring;

- Dependence on air temperature.

The effectiveness of fire extinguishing using sprinkler systems is also due to the fact that water extinguishes not only the fire itself, but also wets the surrounding surfaces and objects, which significantly reduces the risk of their fire.

Automatic sprinkler fire extinguishing operates without human intervention, but is part of a single system fire safety. Pressure sensors are triggered when the pressure in the supply pipelines drops and send an alarm to the central consoles fire protection systems alarms. Primary fire extinguishing is the initial part of extinguishing a fire.

Dry fire sprinkler systems

The use of classic sprinkler systems is limited to the use of water as a working substance. At subzero temperatures, it can freeze and not only paralyze the operation of the system as a whole, but also destroy its supply pipes, which must be filled almost constantly. Application chemical compositions to lower the freezing point is not very justified, due to the possibility of the appearance of sedimentary components that clog the devices, leading to loss of performance.But a solution was found here too - a dry sprinkler fire extinguishing system. It is called dry because in standby mode the underwater pipelines are filled not with water, but with compressed air. In many ways this became possible when steel pipes began to be replaced by plastic ones, capable of not only withstanding significant pressure, but also not being subject to corrosion when interacting with atmospheric oxygen.

The operation of a dry sprinkler system is also based on the application of the fundamental laws of physics. When one of the sprinklers is triggered, that is, when one of the fusible partitions or inserts is destroyed, compressed air will escape through the valve and the necessary vacuum will arise in the pipe, slightly higher than usual Atmosphere pressure. This will trigger the valves of the water system, which is located in a warm room or underground and is not susceptible to freezing.

Water from this system fills the pipes and is sprayed onto the trigger sprayer. Modern systems equipped with devices for accelerated network purging. When one sprinkler is activated to relieve pressure, the others also open, and the pressure in the pipelines drops almost instantly.

Due to the complexity and constant readiness of the system for operation, the design and maintenance of fire sprinkler systems is carried out only by organizations that have the necessary licenses to carry out work of this kind. Sprinkler systems are certified fire-fighting facilities, and all their parameters are strictly regulated by the relevant GOSTs and SNiPs.

Deluge fire extinguishing systems

A variant of sprinkler systems are deluge fire extinguishing systems, although most experts consider them independent system fire extinguishing Pipelines are installed according to the same schemes as in sprinkler networks. But the main difference between sprinkler and deluge fire extinguishing systems is the method of excitation. Deluge system nozzles are activated by a signal from a central control panel or smoke detector rather than by a thermal switch. In many cases, this reduces the response inertia of the system and increases its efficiency.Deluge systems are used on objects of any type and purpose. The difference can only be in the condition of the pipelines. Dry systems are used in unheated facilities or any other points where the possibility of an explosion or sudden intense fire is excluded. In all other cases, water-filled deluge units are installed.

fire safety standards

state standards on fire safety