A fire hydrant is a device designed to provide convenient water intake from the water supply network.

The main application is as a connection point that is used to directly extinguish a fire or fill a fire truck tank. In addition, it is often used for reclamation work.

There are two main types of fire hydrants, which are distinguished by installation method:

- External - the working part with connection points is located above the ground;

- Underground - mounted in wells equipped with hatches. Underground installation is typical for Russia.

All hydrants, regardless of installation location, are equipped with locks that can only be opened with a special key.

Installation Rules

Installation of hydrants is carried out in accordance with SNiP 2.04.01-85 “Systems fire-fighting water supply"and SP 8.13130.2009 "systems fire protection" According to the regulations, the placement of a fire hydrant must meet the following requirements:

- Within 50 to 100 m from any structure;

- The location should take into account the possibility of unobstructed routing of the hoses;

- The distance to the roadway is no more than 2.5 m and at the same time to the wall of the house at least 5 m;

- The diameter of the pipe of the household water supply network for the city must be at least 100 mm, for rural areas 75 mm is allowed.

Quantity calculation and location

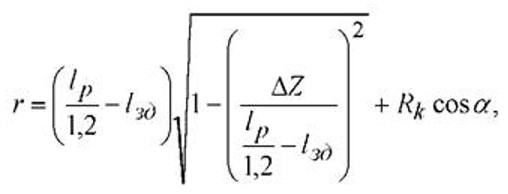

When calculating the required number of connections and their location, it is necessary to take into account the radius of action of the fire hydrant, SNiP 2.08.02-85, produced according to the formula:  Where:

Where:

l r– radius of permissible length of the fire hose;

1,2

– coefficient of additional length when taking into account bends and unevenness of the base;

α

– optimal angle tilting a compact section of water jet Rk ;

ΔZ

– the difference between the surface level of the structure and the height of the pump;

l building– minimal required length fire hose along the height of the structure.

We define l building(fire hose length):

Where:

Where:

n

– number of floors of the building;

k

– floor height ;

The formula is valid only when the sleeves are laid vertically. When using a creeping laying, it is necessary to take triple the height of the floor of the structure.

If the autopump is located approximately at the same level with the column, and the angle of the effective jet is assumed to be optimal 60°, then the radius of the effective action of the hydrant can be determined using a simplified formula. ![]()

According to the determined radii of effective extinguishing, a map of the area is drawn up.

Fire hydrants must be located so as to provide a water supply of at least 15 l/s to any building in the serviced area.

Location of the hydrant inside the well

- Hydrants are mainly produced, the working part of which has a height of 1.5 m;

- The external dimensions of the pipe have a diameter of up to 400 mm; with such dimensions, the distance to the internal walls of the well should be at least 0.3 m; with dimensions of 500-600 mm - 0.5 m; if the pipe diameter is more than 600 mm, there should be no distance between it and the well machines less than 0.7 m.

- From the flange stand to the wall of the well there should be 0.3 m with a diameter of up to 400 mm and more than 0.5 m if the diameter is more than 400 mm.

- From the bottom of the pipe to the bottom of the well there should be 0.25, 0.30, 0.35 m, respectively;

- From the top rod to the hatch 0.3 m, from the flywheel 0.5 m.

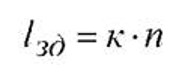

- Fire stand flanged;

- Sealing gasket for fire hydrant;

- Sealing gasket;

- Fire hydrant.

Installation sequence

Features of using the device and responsible person

In addition to testing the device for operability after installation, in accordance with SP 8.13130.2009 “Fire protection systems...” and Russian Government Decree No. 390 dated April 25, 2012 “On fire regulations in the Russian Federation,” it is necessary to carry out systematic inspections and checks of the hydrant’s readiness for operation , with frequency once every six months, spring and autumn are recommended. The results of the inspection are recorded in a report, which is signed by the inspectors and responsible persons.

Who is in charge of the fire hydrant? The manager or person appointed responsible for fire safety organizations. The person responsible must ensure:

- Free access to PG regardless of time of day and production processes. This is especially important in winter time, when it is necessary to clear the manhole cover from snow and ice and clear all access routes.

- If the water pressure in the pipeline supplying the steam generator drops or when individual sections of it are disconnected, along which there are tie-ins, you must immediately notify representatives of the fire department of the nearest department of the Ministry of Emergency Situations about the accident;

- How are signs installed on outdoor fire hydrants? In accordance with SP 8.13130.2009, a fire hydrant indicator must meet the following requirements:

- The sign must be made either three-dimensional with a lamp installed in the middle, or flat, but covered with reflective paint that is resistant to atmospheric phenomena and does not fade in the sun.

- Signs are installed on individual poles, walls of buildings and structures that are visible from the roadway. Mounting height 2-2.5 m.

- The sign should contain information about the location of the hydrant, the distance to it and an arrow indicating the direction, and there should also be a mark on the diameter.

Ensuring performance

Service and maintenance is carried out twice a year, its purpose is to ensure constant operational readiness of the device. The list of work that needs to be done includes:

- Checking the condition of the well hatch for integrity and tightness;

- Checking the main working parts of the hydrant. Nipple for presence and integrity of threads, body, cap and rod for cracks or other damage.

- Presence of rainwater or water leaking from the steam generator in the well;

- Integrity and tightness of sealing gaskets or valve;

- Easy to unscrew the valve.

Installed fire pump and a test run is carried out.

Fire hydrant installation

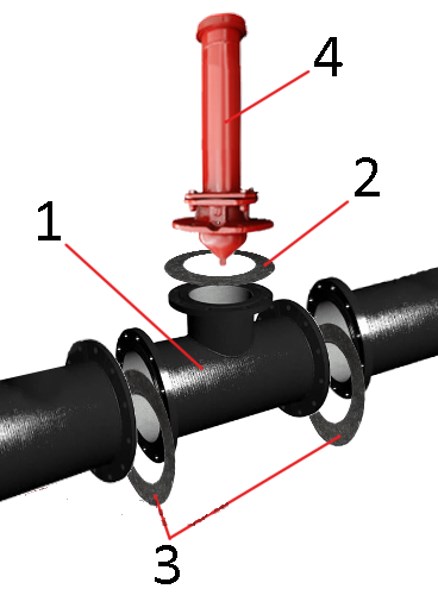

It is quite common to see a fire hydrant in a well. This is necessary to protect the house from fire.

There are currently a large number of this type of devices.

Types of fire hydrants

Fire hydrants, which are most often used in suburban areas and can be of two types:

- Underground (in a well).

- Aboveground (without wells).

Note. They differ in the principles of their design and installation. They also have differences in the water supply scheme. See photos with examples of these types of equipment.

Installing fire hydrants in a well is very popular. This is due to the fact that there will be an uninterrupted supply of water in the event of a fire.

How the work is carried out:

- They are installed at the bottom of the well so that their tap is visible on the surface. Such devices are manufactured strictly in accordance with GOST. They have various sizes. They all have similar forms.

- They are used if cold water supply occurs with a liquid temperature of 5 to 50 degrees. At sub-zero temperature such a hydrant cannot be used.

The water pressure should be up to 10 MPa. - They are located in the well only in a vertical state.

Advice. Before installation, it is imperative to test the equipment for normal and high-quality operation.

- There are special stands for installing hydrants. They are washed with well water before installation. The height of the hydrant can be at intervals of 250 mm - 1250 - 3500 mm.

- The valve with these dimensions opens by 24-30 mm. Hydrants have special holes so that hoses can be connected to them in case of fire.

Advice. The hoses must be of the same diameter as the valve itself (hole). This will make it possible to screw it securely.

- Very often, when using this type of hydrant, a fire line is built along the entire perimeter of the site. It consists of numerous hoses or plastic pipes that are laid along the perimeter of strategic objects.

- As a rule, there are specific instructions for installing any fire hydrant. It shows the diagram and sequence of actions for connecting the equipment.

There are two types of underground hydrant stands:

- Dead end.

- Checkpoint.

So:

- The height of the hydrant can be different and when choosing it, it is worth taking into account the depth of soil freezing in the region. A fire column is screwed onto the hydrant.

It in turn has two pipes that ensure an uninterrupted supply of water if necessary. - Eat modern models such equipment, which are additionally equipped with functions for automatically draining water after using a fire hydrant. Such measures are very important for the long-term use of this equipment.

- The service life of a fire well hydrant is about 50 years. Thanks to innovations in production technologies, it can also be used outside.

There are a huge number of devices for this. It is also worth noting that when installing a fire hydrant, you need to take into account the degree of soil freezing in the areas.

Advice. If the depth of soil freezing is quite large and reaches more than 2 meters, then it is best to place the equipment on the surface.

- A fire hydrant has several outlets for connecting a hose. They can function in parallel or separately. There are special plugs for this.

Installation of a hydrant in a well must also include the location groundwater. They can flood the equipment, rendering it unusable.

Diagram of a fire hydrant in a well

Installation of a fire hydrant in a well is carried out in several stages. Initially, you need to choose a well or build it yourself.

There should always be water in it so that if necessary it can be used.

So:

- In the well, the pipe is removed from the water supply. It will be mandatory to secure and seal the connection between the pipe and the hydrant rubber gasket. Its thickness should not be less than 4-5 mm.

- After the rubber band is put on the water supply, a fire hydrant is installed. It is secured using special bolts that are located on the equipment stand.

Advice. The fire hydrant hatch must be tightly closed.

- Firefighters who arrive at the scene of a call will be able to safely open the hatch and connect hoses to it to extinguish the fire.

Advice. In the event of a fire, you can get rid of the source of fire with your own hands.

For this purpose, a fire line is provided or hoses are simply connected. Actions will be similar to firefighters.

If the well fire hydrant does not have independent system draining the water, you need to drain the water from it in the winter to protect it from freezing.

What should be the well for a fire hydrant?

Detailing of a well with a fire hydrant is usually done by professionals. But you can do it yourself if you know certain rules for using this equipment.

Let's take a closer look:

- It is necessary to build a well that is not too deep. Water must be supplied to it from a well.

It is not necessary that the water be purified from impurities. The most important thing is that there should be no stones in it. - The width of the well is at least 80 cm. With these parameters, you can freely turn the equipment on and off.

- The well is made from reinforced concrete rings or plastic pipes with a large diameter. It is not recommended to simply lower equipment into a dug but unfinished well.

If the soil moves slightly, it can become covered. - The installation diagram for a fire hydrant in a well is shown in the instructions for using the equipment and it is different for each type of equipment.

Advice. Installing a fire hydrant in a well should only be done by professionals, since if the equipment is connected incorrectly, there is a risk of it breaking.

Above ground fire hydrants

Example of an above-ground device

Example of an above-ground device A wellless hydrant is more complex design. The principle of its operation and internal components are similar to underground hydrants, only it also has a protective metal box.

Let's take a closer look:

- Such equipment can be found in almost any area. They are installed directly on the surface of the ground or a special hatch. It will be necessary to have a nearby water source to which the hydrant is connected.

- It consists of several waste materials for hoses and hydraulics. It is turned on by unscrewing a special tap.

It will be impossible to unscrew the tap on your own and a key is used for this. - It is very important to completely empty such a hydrant of water at fairly low temperatures in winter. It may freeze and it will be impossible to use it in the future.

- It also has equipment and additional features. Overhead hydrants are increasingly equipped with automatic switching on or exemption from water in the case of equipment use.

- Their price is several times higher than that of underground hydrants and this is due to the versatility of their use.

Advice. If this type of equipment is used on suburban area, then for its effective use it is necessary to build a fire line, as when using an underground hydrant.

- Such measures will make it possible to eliminate the source of fire in a very short period of time and thereby save the home.

- It is worth considering that the hydrant is installed directly on the water supply pipe. This could be a well with a hatch or a borehole.

It's different at every site. The purity and quality of water for such equipment also does not matter.

The most important thing is that no foreign objects get into the hydrant. - A wellless hydrant can be any size. Height reaches 75 cm.

The width can be 30-40-50 cm. It all depends on the required parameters.

Water is supplied to it automatically when the tap is unscrewed. It already has a small pump built into it that helps pump in water, albeit in small quantities.

Zakharov Alexander

Which should be minimum distance from the cover of an underground hydrant to the edge of the well in which this hydrant is installed and what document regulates this issue?

Installation regulations and technical repairs fire hydrants

II. OPERATING REQUIREMENTS

Hydrants in water supply wells are installed vertically using a fire stand in accordance with GOST 5525-61, which is a shaped part of the water supply network. The hydrant is connected to the fire stand using an adapter flange. The hydrant axis should be located no closer than 175mm and no further than 200mm from the wall of the well neck. The distance from the well cover to the top of the fire hydrant should not exceed 400mm and be less than 150mm. Installation and maintenance of hydrants on the water supply network is carried out in accordance with the requirements of GOST 12.3.006-75, GOST 12.4.009-83.

The placement of hydrants in wells should ensure free installation of the well cover and opening of the hydrant safety cover, complete screwing of the fire column and ease of installation. repair work. The hydrant is opened and closed manually using a fire pump key.

The technical condition of all fire hydrants operating on the water supply network is checked twice a year: in spring and autumn.

Hydrant maintenance includes checking:

— the operability of the hydrant with the installation of a fire column and determination of the throughput (water flow) of the hydrant.

— serviceability of the hatch and cover of the water well, the cover and thread of the nipple, the square of the rod tip;

— valve tightness;

— ease of opening and closing the valve;

— presence of water in the hydrant body;

— compliance with the size and placement of the GHG.

Comments (5)

Borisenko Sergey

During the inspection, inspectors from our department discovered the presence of water in the fire hydrant well. Maintenance and pumping of water, according to the order, is carried out in the first days of the month. Do they have the right to punish us?

Answer: if the water in the well is not any obstacle to the intake of water for firefighting needs, then there is no corpus delicti. If there is no corpus delicti, there are no perpetrators.

Rudenko Olga

There is a fire hydrant installed in the garage, which is not functioning (water is not supplied to it) and an automatic fire extinguishing system is installed.

The fire inspector demands to justify the uselessness of the hydrant (in writing), what can you refer to?There should not be a fire hydrant inside the building. This is probably why there is no water supplied to it. Since there is no water supply, it has never been put into operation, is not registered with anyone and no one maintains it.

It is not your trouble to justify to the inspector that the hydrant is unnecessary. It is the inspector, as the prosecuting party, who must prove the validity of his claims.Novel

Is tapping into a water supply in a well with a fire hydrant allowed?

No, it is not allowed.

A fire hydrant well is a structure for installation and maintenance fire equipment. Placing any other equipment in a fire hydrant well is prohibited.Gennady Dmitriev. Tula. Russia

The inspectors demanded that a stationary ladder be installed in the fire hydrant well. No matter how many regulations I looked at, I didn’t find this requirement anywhere. Tell me, are the inspectors right?

There is a requirement for drainage devices (clamps, ladders) in wells on water supply networks.

(clause 11.4 R 53961-2010; clause 2.12G OST 12.3.006-75)Romanyuk Grigory. Samara

We are being forced to replace fire hydrant manhole covers with covers with symbols. What are these symbols?

On the fire hydrant hatch cover there should be a cast of it symbol- letter "G".

Some companies also use red signal color - they tint hatches with red paint.

(clause 4.5; clause 5.5.1 GOST 3634-99)

In the fight against a destructive element - fire - can be used various means extinguishing. These fire extinguishing methods in our time require the presence of special means- hydrants.

A fire hydrant is a water intake device designed to extinguish fires and localize fires. And since it is an integral part of the fire extinguishing system, a fire hydrant requires careful maintenance.

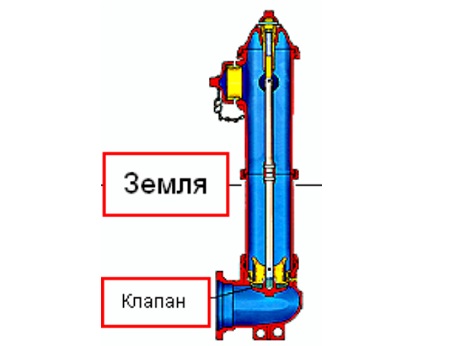

Device

Fire hydrants, according to their design, in our country are divided into two types: Leningrad and Moscow. The second one is more popular due to its affordability, reliability and ease of installation. But, in essence, there is not much difference between these two types.

Image of a fire hydrant structure.

This device (of any type) consists of:

- housings;

- valve body;

- valve;

- pipe;

- rods;

- threaded nipple (for attaching the KPA fire column);

- covers.

These devices are made from cast iron (steel), thanks to which the service life reaches 18 years. In height, hydrants can be 500-3500 mm (from 0.5 m to 3.5 m), depending on the type of equipment.

A fire pump is a device that is used to open and close an underground hydrant. Also, the KPA column is necessary for attaching fire hoses.

Types of devices

There are 2 types of fire hydrants: above-ground and underground. External (above-ground) hydrants are mounted above the ground together with the control valve, and underground ones are installed in wells with hatches; a fire column is installed on them immediately before pumping water.

The underground type of units is most in demand in Russia, since access to water supply networks, laid, in most cases, underground, is possible only with a hydrant and a water pump.

The device must be frost-resistant and have a maximum starting speed.

Before installation, you must ensure that the installation of water intake equipment is not affected by factors such as:

- increased groundwater level;

- excess water that may drain from the surface of the earth;

- violation of the valve installation level;

- failure to comply with operating standards;

- a malfunction of the device, which may cause the water in the riser to freeze.

Installation Requirements

The installation of a fire hydrant must follow certain rules relating to both operational aspects and maintenance. Violation of these rules can lead to irreparable tragic consequences, which must be taken into account when installing and further using fire extinguishing equipment.

When installing this device, the following is taken into account: the number of floors (height) of the structure or building, the total water consumption required to extinguish the fire, throughput of this water intake equipment.

Rules that must be followed when installing a hydrant in a well:

- the distance between the hydrant axis and the wall of the well hatch is at least 175 mm;

- the distance between the end of the riser and the manhole cover is 150-400 mm.

Only a hydrant equipped with a reverse-acting valve can be installed in a flooded well to prevent groundwater from entering the device.

When installing a water intake device, it is necessary to use special supports to prevent water leakage from the system and its separation.

Usage

List of rules for ensuring correct operation fire hydrant:

Before using the fire hydrant, you must first remove the cover, then screw it onto the threaded nipple of the control unit so that the gaskets fit tightly to the surface. Then you need to turn the KAP handle counterclockwise, thereby causing the rod with the coupling and the hydrant spindle adjacent to them to rotate. As a result of rotation of the spindle, the valve opens, and water enters the device body through the passage, which then ends up in the fire column.

After completion of use, the hydrant must be closed by performing all the above steps in reverse order. The remaining water in the structure should be drained through a special channel located in the hydrant pipe (in the flange). The drainage channel must be closed with a special rubber seal when the valve is open.

The list of activities for inspection and maintenance of this equipment includes:

- filling out the audit log and the availability of this device in the organization;

- monitoring and noting changes in the fire water supply system;

- timely provision of information to the management of enterprises and organizations to which the territory with GHGs belongs;

- timely inspection of the integrity of fire hydrants, their repair and replacement of failed devices;

- checking the presence and serviceability of trunks, fire hoses and connection elements.

System test

For proper operation of this device are required preventive measures to check the quick start of water by supplying the hydrant with water. Pressure tests are also checked using a special stand and a pressure gauge with URL - 16 kgf/cm 2 and accuracy class - 1.5. This water intake equipment is checked strictly in accordance with GOST 15150 at least once every 6 months in the summer.

Is it possible in a modern city to fight fire using old-fashioned methods - passing buckets of water along a chain from the pump to the source of the fire? We are sure that everyone who reads these lines will have a smile. You are right - it will not be possible to tame a raging fire in a multi-story building this way.

Therefore, today, to combat this destructive element, they use modern methods and funds. One of them is the installation of fire hydrants (FH).

This is special water intake equipment, which is most often installed in water supply wells and is used to collect water from fire trucks.

Scope of application of GHG

The use of this equipment is mainly intended for large production facilities where the risk of fire is high. But since cast iron fire hydrants are designed for water intake, they can be used not only to fight fire, but also for land reclamation.

In addition, they are installed on almost all water supply networks in populated areas, which allows fire crews to gain unhindered access to water and easily repair hydrants. They are usually equipped with locking devices that can be opened with a special key.

Classification of fire hydrants

This equipment is presented various models. They differ in technical specifications and materials, but perform one function - they allow you to draw water from the water supply system of the facility on which they are installed.

Let's watch the video, a little about them and their application:

Depending on the location of the GHGs there are:

- Underground, which are installed in wells equipped with a hatch;

- External - located above the surface of the earth.

The fire hose on the first ones is attached immediately before use, and on the second ones it is installed together with the equipment. The choice in favor of one of the installation methods depends on the characteristics of the structure and the conditions for the location of fire extinguishing equipment.

Design features of PG

In addition to the installation method, according to which cast iron fire hydrants differ, there are certain nuances in the device. So, according to the design of the device, there are the following types:

- Moscow;

- Leningradsky.

Moreover, the first type is most often used. This is due to the fact that they are easier to connect, have higher reliability and are cheaper.

We will not consider in detail the design of a cast iron fire hydrant, but will limit ourselves to only its three main blocks. Such a device usually includes:

We will not consider in detail the design of a cast iron fire hydrant, but will limit ourselves to only its three main blocks. Such a device usually includes:

- Riser;

- Valve box;

- Hydrant valve;

- Installation head.

All of them are made from gray cast iron and have sufficient long term service reaching 18 years of age. The height of PGs ranges from 500 to 3500 mm.

Installation in accordance with SNIP - everything according to the rules

Such equipment is subject to fairly strict requirements both in terms of maintenance and operation. Violation of them can lead to a tragic outcome and this must be taken into account.

Such equipment is subject to fairly strict requirements both in terms of maintenance and operation. Violation of them can lead to a tragic outcome and this must be taken into account.

According to existing standards When installing fire hydrants, they must be located in such a way that all fire zones are located, regardless of location - underground or on the surface.

Also to ensure it proper operation certain rules must be observed:

First, the waterway must contain required quantity water to extinguish a fire at a specific facility. Usually this compliance is determined by verification and is reflected in special acts.

Secondly, it is necessary to completely eliminate the possibility of ice forming on equipment in the winter season.

Third, the cast-iron fire hydrant must have free access. To better locate it, signs are usually installed indicating the direction of movement.

Fourth, the facility must be equipped with fire hoses and nozzles, which will allow you to quickly connect to the hydrant in the event of a fire.

For reliable installation equipment, special stands are used. They are necessary to separate the flow of water and can prevent leakage from the system. Except correct installation Regular checks of the operating condition of equipment should also be carried out, as well as repair of fire hydrants if they break down.

Each of them implies a mandatory test run of water, preventative work, insulation, removal of contaminants. Each hydrant must be registered with the organizations responsible for the serviceability of the equipment and checked for the presence of water in the system.

PG installation procedure

Fire fighting equipment must have maximum speed start-up and be resistant to low temperatures. The use of fire-type hydrants, especially in the far north, requires that it be insulated and installed according to the following rules:

- There should be free space from the hatch cover to the end;

- It is first necessary to carry out a calculation and find out the distance between the hatch wall and the axle.

If any of the requirements are not met, the equipment may freeze in cold season. The following factors can also lead to this situation:

- High groundwater level exceeding the permissible level;

- Liquid ingress from the surface of the earth;

- Equipment malfunction that can lead to freezing of water in the riser;

- Violation of operating standards;

- The installation level of the ball valve is too high.

In addition, the order of work performed when installing a fire hydrant must be observed. This process begins with the installation of a fire stand on a hard surface. It is selected depending on the diameter of the pipeline and the number of sections connected to it.

Then the stand is connected to the pipeline. Flanges are used for this.

The next step is the location of the hydrant. It must have a vertical position and is connected to the mating flange of the stand using bolts. It is possible to install a fire hydrant both underground and on its surface.

The last step in installing a hydrant is to carry out testing. To do this, a fire column is screwed onto the nipple of the device and water is started.

How to use fire extinguishing equipment

The operation and location of the fire hydrant are as follows. In the working position, it must be located vertically and installed in the well on a special stand. Opening and closing the hydrant is done manually using a key. More detailed information contained in the instructions for the fire column.

Let's watch the video, a little about operation:

Water is drawn from the hydrant only in the event of a fire or during maintenance. For ease of use, such equipment must be located along the road and have a distance to the roadway of no more than 2.5 m. The placement of fire hydrants must ensure the ability to extinguish a fire in each building located along a certain water network.

However, water consumption and equipment throughput must be taken into account. When installing a hydrant underground, a special anti-corrosion coating equipment, and if located outside, shelter from fire will be required.