n1.doc

MINISTRY OF EDUCATION AND SCIENCE OF UKRAINEDONETSK STATE INSTITUTE OF ARTIFICIAL INTELLIGENCE

Department of Labor Safety and Ecology

Essay

On the topic: “Methods and means of extinguishing fires”

Checked:

Nikishaeva S.S.

(date, signature)

Performed:

Art. gr. IS-09a

(date, signature) Filonova E.A.

Introduction

The first phase is characterized by the process of flame propagation to the maximum coverage of the surface area of the volume of combustible materials. Its onset is characterized by relatively low temperatures and flame front propagation speeds. This phase ends with an increase in the danger of an increase in fire, since the flame at this time reaches maximum sizes, which creates the possibility of its spread to nearby objects and the merging of individual fires into a single column of flame.

The second phase is characterized by processes of stable maximum combustion up to the time of combustion of the bulk of substances and destruction of the structure.

The third phase of a fire is the process of burning out materials and collapsing structures. The burning rate during this period is low, which causes a significant decrease in thermal radiation.

The choice of methods and techniques for extinguishing fires depends on the specific conditions and situation in the fire zone, the availability of special units (formations) and technical means that can be used to extinguish the fire.

Fire extinguishing methods

Open, extensive fires are usually extinguished by cooling or isolation, and gradual localization of combustion sources. Fires of petroleum products in tanks are eliminated by insulating each tank. When planning fire extinguishing tactics, it is necessary to remember that when a fire occurs in buildings and structures, the temperature quickly rises, the premises become significantly smoky, the fire spreads in hidden ways, which causes invisible damage to structures load-bearing capacity. Typically, strong flames from windows and doorways is evidence of high combustion rates or combustion of large quantities of materials. A significant amount of thick smoke is a sign of combustion due to lack of oxygen. At the initial stage of destruction individual designs indicate: peeling of the protective layer of concrete, deformation of reinforcement reinforced concrete columns, formation of cracks in spans and supports of reinforced concrete beams, deflections and characteristic cracking of wooden beams

Possible methods of extinguishing fires in populated areas

It is advisable to extinguish primary fires using

hydrants, fire extinguishers, cover with sand or earth, and also apply

other available means. Isolated sources of combustion that do not represent

dangers for the spread of fire are localized as much as possible and left until the combustible materials burn out completely. The term individual fires refers to areas in which fires occur in separate areas, in separate zones and production facilities. Such fires are dispersed throughout the area, which allows them to be quickly extinguished using all available forces and means. When extinguishing large and widespread fires, the area affected by fire is divided into separate areas. The boundaries of the sites are adopted on the basis of determining the location for the convenience of managing the work of special units (formations), since a zone of massive and continuous fires is an area where such a large number of fires and fires occur that the passage and presence of the relevant units in it without carrying out localization measures or extinguishing is impossible, and conducting rescue

work is difficult. Such zones arise in compact forest conditions

massifs, accumulations of large quantities of flammable materials, as well as in

conditions of continuous development. In the latter case, special units (formations) can be installed between floors and along the perimeter of buildings, in separate areas of fire spread. Forest fires are the uncontrolled burning of vegetation,

spreading throughout the forest. Depending on which

Fire spreads at heights; forest fires are divided into ground fires, underground fires and crown fires. But anyway, liquidation forest fires consists of stopping the movement of the fire front, localizing it to individual outbreaks, eliminating the latter and organizing the protection of the area in order to prevent new fires.

Peat fires are the result of ignition of layers of peat on different depths. They cover large areas. Peat burns slowly, to the depth of its occurrence. Burnt-out areas are dangerous because sections of roads, equipment, people, and houses fall into them. It follows from this that extinguishing underground peat fires is extremely difficult. This is due to the fact that peat burns in all directions of the layers. Therefore, the main method of extinguishing such a fire is to dig in the burning area on all sides with ditches 0.7 m wide and deep to the limit of the opening of the underlying peat layer of sediment.

Fire extinguishing agents

Fire extinguishing agents include: water, chemical and air-mechanical foams, aqueous solutions of salts, inert and non-flammable gases, water vapor, halocarbon fire extinguishing compounds and dry fire extinguishing powders.

Water - the most common and accessible remedy extinguishing. Once in the combustion zone, it heats up and evaporates, absorbing a large amount of heat, which helps cool the combustible substances. When it evaporates, steam is formed (from 1 liter of water - more than 1700 liters of steam), which limits the access of air to the combustion site. Water is used to extinguish solid flammable substances and materials, heavy oil products, as well as to create water curtains and cool objects located near the fire. Finely sprayed water can extinguish even flammable liquids. To extinguish poorly wetted substances (cotton, peat), substances are introduced into it that reduce surface tension.

Foam There are two types: chemical and air-mechanical.

Chemical foam is formed by the interaction of alkaline and acidic solutions in the presence of foaming agents.

Air-mechanical foam is a mixture of air (90%), water (9.7%) and foaming agent (0.3%). Spreading over the surface of the burning liquid, it blocks the source, stopping the access of air oxygen. Foam can also be used to extinguish solid flammable materials.

Inert and non-flammable gases (carbon dioxide, nitrogen, water vapor) reduce the oxygen concentration in the combustion area. They can extinguish any fires, including electrical installations. The exception is carbon dioxide, which cannot be used to extinguish alkali metals, since this results in a reduction reaction.

Fire extinguishing agents - aqueous solutions of salts. Solutions of sodium bicarbonate, calcium and ammonium chlorides, Glauber's salt, etc. are common. Salts, precipitating from an aqueous solution, form insulating films on the surface.

Halocarbon extinguishing agents allow you to slow down combustion reactions. These include: tetrafluorodibromomethane (freon 114B2), methylene bromide, trifluorobromomethane (freon 13B1), etc. These compositions have a high density, which increases their efficiency, and low freezing temperatures make it possible to use low temperatures. They can extinguish any fires, including live electrical installations.

Fire extinguishing powders They are finely dispersed mineral salts with various additives that prevent caking and clumping. Their fire extinguishing ability is several times greater than that of halocarbons. They are universal because they suppress the combustion of metals that cannot be extinguished with water. The composition of the powders includes: sodium bicarbonate, diammonium phosphate, ammophos, silica gel, etc.

All types fire equipment are divided into the following groups:

fire engines (cars and motor pumps);

fire extinguishing installations;

fire extinguishers;

facilities fire alarm;

fire rescue devices;

firefighter hand tool;

fire equipment.

Primary fire extinguishing agents are used to extinguish small fires. These include: fire nozzles operating from an internal fire pipeline, fire extinguishers, dry sand, asbestos blankets, etc.

Fire fighting equipment locations must be marked with signs. Access to fire extinguishers and other fire extinguishing equipment should be convenient and unobstructed.

In production of categories A, B, B and E, stationary fire extinguishing installations are used, in which all elements are installed and are constantly ready for action. They can be automatic or remote (operated by people).

Sprinkler installations have become the most widespread. They are a network water pipes located under the ceiling. There is always water in the pipes. Irrigation heads - sprinklers - are installed in them at certain distances (Fig. 1.a).

IN normal conditions The hole in the sprinkler head is closed with a low-fusible lock valve. When the temperature rises to 70...180 o C, the lock melts and is thrown away, water enters the head, hits the socket and splashes.

In such installations, only the heads that are in the high temperature zone are opened. Their number is determined based on the condition: one sprinkler irrigates 9... 12 m2 of floor area.

However, sprinklers have inertia - they open 2...3 minutes after the temperature in the room rises.

If water needs to be supplied to the entire area at once, then deluge installations are used, in which a deluge is installed instead of a sprinkler head (Fig.1.b). The hole in the latter is open, so the installation is activated by a remote valve, supplying water to all pipes at once.

In addition to water systems, foam sprinklers and deluge systems are used. To create foam, they are equipped with special sprinklers and generators.

Enterprises also use stationary fire extinguishing installations - steam, air-foam, aerosol and powder.

Fire extinguishers are designed to extinguish fires in the initial stages of their development. They are divided into air-foam, chemical foam, liquid, carbon dioxide, aerosol and powder.

The most common chemical foam fire extinguishers are OHP-10, OP-M and OP-9MM. The OHP-10 fire extinguisher (Fig. 2) is a steel vessel with a capacity of about 10 liters with a neck and a closed lid equipped with a locking device. The latter consists of a rod, a spring and a rubber valve designed to close a polyethylene cup inserted inside the fire extinguisher for the acid part of the fire extinguisher charge.

A nozzle with a hole (spray) is installed on the neck of the vessel. The hole is closed with a membrane that prevents liquid from leaking out of the fire extinguisher. It bursts at a pressure of 0.08-0.14 MPa. The fire extinguisher body contains the alkaline part of the charge - an aqueous solution of bicarbonate of soda with the addition of a foaming agent.

To activate the fire extinguisher, turn the locking device handle 180 o, turn the fire extinguisher upside down and point the nozzle at the source of fire. When you turn the handle, the acid glass opens and the acid and alkaline parts of the charge mix, as a result of their interaction, carbon dioxide is formed, which intensively mixes the liquid, forming foam. The pressure in the fire extinguisher body increases, and the foam is thrown out through the nozzle.

For extinguishing various substances (except for alkali and alkaline earth metals) and electrical installations under voltage up to 10 kV, the industry produces carbon dioxide fire extinguishers OU-2 (Fig. 9.3.), OU-5, OU-8, OU-25, OU-80 and OU-400. Carbon dioxide in fire extinguisher cylinders is under pressure of 6... 15 MPa.

To activate the fire extinguisher, its socket is directed to the source of combustion and the shutter trigger is pressed. When leaving the cylinder, the gas expands, cools and comes out in the form of flakes.

Literature

T.A. Hwang, P.A. Hwang "Life Safety". Rostov-on-Don, Phoenix publishing house, 2002. – 175s.

IN AND. Bondin, A.V. Lysenko "Life Safety". Rostov-on-Don, Phoenix publishing house, 2003 - 76 p.

L.V. Bondarenko, V.V. Persiyanov, V.A. Kudryavtsev, V.G. Tkachev “Life Safety”. Moscow, 2001 - 38 p.

3.3.1. Fire extinguishing apparatus

Fire extinguishing apparatus is divided into mobile (fire fighting vehicles), stationary units and fire extinguishers (manual up to 10 liters and mobile and stationary with a volume above 25 liters).

Mobile installations include fire trucks equipped with manual or monitor water guns, and motor pumps for drawing water from external bodies of water. Firefighting vehicles are divided into tankers that deliver water and a foam solution to the fire and are equipped with barrels for supplying water or air-mechanical foam of various expansion rates, and special ones designed for other fire extinguishing agents or for certain objects.

TO stationary systems include internal and external fire water supply, sprinkler and deluge installations. Stationary installations are designed to extinguish fires in the initial stages of their occurrence without human intervention. They are installed in buildings and structures, as well as to protect external technological installations. According to the fire extinguishing agents used, they are divided into water, foam, gas, powder and steam. Stationary installations can be automatic or manual with remote start.

Water sprinkler systems are used in rooms with an air temperature of at least 4° C. Before the starting device, the pipelines are filled with antifreeze. The outlet in the sprinkler head is usually closed with a fusible lock. As the temperature rises, the lock melts and water splashes out. Response time – 2–3 minutes.

Deluge units are used in rooms in high fire hazard. When flammable liquids burn, these installations localize the fire and prevent the spread of fire. All pipelines of these installations are constantly filled with water, so the response time is much shorter than that of sprinkler installations.

3.3.2. Fire extinguishers

The most common primary fire extinguishing equipment is fire extinguishers. They use foaming compounds, inert gases and powder formulations.

Fire extinguishers are marked with letters characterizing the type of fire extinguisher by category, and a number indicating its capacity (volume).

Fire extinguishers – technical devices, designed to extinguish fires at the initial stage of their occurrence. Fire extinguishers are classified according to the type of used fire extinguishing agent, the volume of the body and the method of supplying the fire extinguishing agent.

By type of fire extinguishing agent:

· foam;

· gas;

· powder;

· combined.

By body volume:

· manual small-capacity ones with a body volume of up to 5 liters;

· industrial manual with body volume from 5 to 10 l;

· stationary and mobile with a body volume of over 10 liters.

According to the method of supplying the fire extinguishing agent:

· under the pressure of gases formed as a result chemical reaction charge components;

· under the pressure of gases supplied from a special canister located in the fire extinguisher body;

· under the pressure of gases pumped into the fire extinguisher body;

· under the fire extinguishing agent’s own pressure.

By type of starting devices:

· with valve shutter;

· with a pistol-type locking and starting device;

· with start-up from a constant pressure source.

Constant improvement of the design, increasing such indicators as reliability, manufacturability, unification, leads to the creation of new, more advanced fire extinguishers.

Fire extinguishers are marked with letters characterizing the type of fire extinguisher and numbers indicating its capacity.

Foam fire extinguishers.

Designed to extinguish fires with fire extinguishing foams: chemical (OCP fire extinguishers) or air-mechanical (OVP fire extinguishers).

Foam fire extinguishers are used to extinguish almost all incipient fires with foam. solids, as well as flammable and some flammable liquids in an area of no more than 1 m2. Extinguish fires with foam electrical installations and live electrical networks are not allowed, since it is a conductor electric current. In addition, foam fire extinguishers cannot be used when extinguishing alkali metals sodium and potassium, because when they interact with water in the foam, they release hydrogen, which intensifies combustion, as well as when extinguishing alcohols, since they absorb water, dissolving in it, and when it gets on them, the foam quickly collapses.

The disadvantages of foam fire extinguishers include a narrow temperature range of use ((+5)÷(+45))°C, high corrosiveness of the charge, the possibility of damage to the extinguishing object, and the need for annual recharging.

Of the chemical foam fire extinguishers, the most widely used fire extinguishers are: OKHP-10, OP-M and OP-9MM (thick foam chemical), OKVP-10 (air-foam chemical).

Chemical foam fire extinguisher type OHP-10 (Fig. 3.1) is designed to extinguish solid fires organic materials, the combustion of which is accompanied by smoldering, as well as various flammable liquids in an area of no more than 1 m 2. OHP-10 It is a welded steel body with a neck closed by a lid with a locking device. A locking device having a rod, a spring and a rubber valve is designed to close a polyethylene cup inserted inside the fire extinguisher for the acid part of the fire extinguisher charge. The acid part is an aqueous mixture of sulfuric acid and iron sulfate. The alkaline part of the charge (an aqueous solution of sodium bicarbonate with licorice extract) is poured into the fire extinguisher body. At the neck of the body there is a nozzle with a hole (spray). The hole is closed with a membrane that prevents liquid from leaking out of the fire extinguisher. The membrane breaks (opens) at a pressure of (0.08÷0.14) MPa.

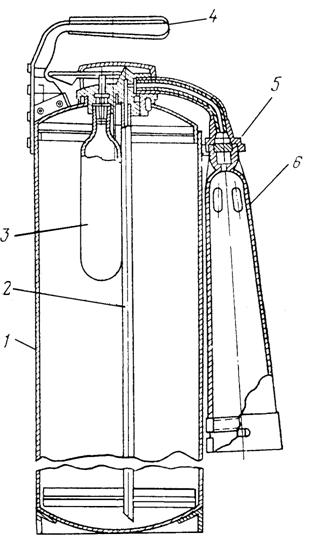

To activate the OHP-10 fire extinguisher, turn the handle (4) of the locking device 180°, turn the fire extinguisher upside down and direct the spray to the source of fire. When you turn the handle, the valve (9) covering the neck (3) of the acid glass (2) rises, the acid solution freely pours out of the glass and mixes with the solution of the alkaline part of the charge. The carbon dioxide formed as a result of the reaction intensively mixes the liquid and is enveloped in a film of aqueous solution, forming foam bubbles. The pressure in the fire extinguisher body rises sharply, and the foam is thrown out through the spray. When extinguishing solid materials, the jet is directed directly at the burning object under the flame, to the places of the most active combustion. Extinguishing burning liquids spilled on an open surface begins from the edges, gradually covering the entire burning surface with foam.

The chemical air-foam fire extinguisher OKVP-10 is similar to OKHP-10 in design, but additionally has a special foam nozzle that is screwed onto the fire extinguisher spray and provides air suction. Due to this, when the chemical foam flows out, air-mechanical foam is also formed. In addition, in this fire extinguisher the alkaline part of the charge is enriched with a small addition of foaming agent type PO-1. Air-foam fire extinguishers are manual (OVP-5 and ORP-10) and stationary (OVP-100, OVPU-250).

Rice. 3.1. Chemical foam fire extinguisher OHP-10

Air-foam fire extinguisher OVP-10 (Fig. 3.2) consists of a steel body (1), which contains a (4÷6)% aqueous solution of foaming agent PO-1, a can high pressure with carbon dioxide (3), for pushing out the charge, a lid with a locking and starting device, a siphon tube (2) and a bell-nozzle (6) for obtaining high-expansion air-mechanical foam. The fire extinguisher is activated by pressing the trigger lever with your hand, as a result of which the seal breaks and the rod pierces the membrane of the carbon dioxide cylinder. The latter, leaving the cylinder through the dosing hole, creates pressure in the fire extinguisher body, under the influence of which the solution flows through the siphon tube through the sprayer (5) into the socket, where, as a result of mixing the aqueous solution of the foam concentrate with air, air-mechanical foam is formed.

The durability of the resulting air-mechanical foam (the time from the moment of its formation to complete disintegration) is 20 minutes. Durability of chemical foam is 40 minutes. The fire extinguisher cannot be used to extinguish substances that burn without access to air (cotton, pyroxylin), burning metals (alkali - sodium, etc. and light - magnesium, etc.). Do not use to extinguish live electrical installations.

The fire extinguisher is used at ambient temperatures from +3 to +50°C.

Rice. 3.2. Air foam fire extinguisher

OVP-10:

1 – body; 2 – siphon tube; 3 – balloon; 4 – handle;

5 – sprayer; 6 – socket with mesh

Gas fire extinguishers.

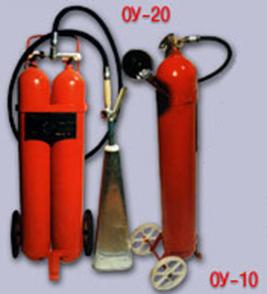

Carbon dioxide fire extinguishers Both manual (OU-2, OU-5, OU-8) and mobile (OU-10, OU-20) are produced.

Hand-held fire extinguishers (Fig. 3.3) are identical in design and consist of a high-strength steel cylinder into the neck of which a valve-type or pistol-type shut-off device is screwed into the neck, a siphon tube that serves to supply carbon dioxide from the cylinder to the shut-off device, and a snow blower socket . Fire extinguisher cylinders are filled with liquid carbon dioxide under a pressure of 6÷7 MPa.

In the OU-2 fire extinguisher (Fig. 3.4), the socket is connected to the shut-off head through an armored hose 0.8 m long.Carbon dioxide fire extinguishers OU-5 are designed to extinguish fires of various flammable substances, the combustion of which cannot occur without air access, in industrial enterprises, on vehicles(railway, road, sea transport), fires of electrical installations under voltage of no more than 1000 V, in museums, art galleries, archives.

Rice. 3.3. Carbon dioxide mobile fire extinguishers

Carbon dioxide fire extinguishers are also designed to extinguish liquid and gaseous substances. They are also used in cases where the use of water does not give a positive effect or is undesirable. Gas stations and areas are equipped with carbon dioxide fire extinguishers industrial enterprises, warehouses, fire panels in paint shops, areas of office buildings, offices, apartments, etc.

The disadvantages of the OU include the fact that when working with it, you cannot touch the fire extinguisher socket with bare parts of the body, since when carbon dioxide leaves the socket, a temperature of -75°C is created, which can lead to isothermal burns. The portable carbon dioxide fire extinguisher OU-5 is prohibited from being installed near heating devices, it must be protected from exposure sun rays. Temperature conditions for storage and use of carbon dioxide fire extinguishers are from -40°C to +50°C.

When using a carbon dioxide fire extinguisher, it is necessary to bring it to the source of the fire, taking into account a distance safe from heat exposure. Pull out the pin, point the flare at the source of fire and press the valve handle of the shut-off device. In cases of fire in the open air, extinguish only from the windward side. Be careful when releasing the charge from the socket, as its surface temperature drops to ((- 60)÷(-70)) °C. In addition, electrostatic stress can be concentrated on the surface of the bell, which can penetrate the dielectric glove. When extinguishing electrical installations that are under voltage, it is not allowed to bring the socket closer than 1 m to the electrical installation and the flame.

|

|

|

|

|

Rice. 3.4. Carbon dioxide fire extinguishers: a – fire extinguisher OU-2; b – fire extinguisher OU-5; c – Fire extinguisher OU-8 |

||

Powder fire extinguishers.

To extinguish small fires of flammable liquids, gases, electrical installations with voltages up to 1000 V, metals and their alloys, powder fire extinguishers OP-1, OP-25, OP-10 are used.

Powder fire extinguisher OP-1 “Sputnik” with a capacity of 1 liter is used to extinguish small fires on cars and agricultural machines. Consists of a body, mesh and lid made of polyethylene. Filled with PSB (dry bicarbonate powder), consisting of 88% sodium bicarbonate with the addition of 10% TKB talc, metal stearates (iron, aluminum, calcium magnesium, zinc) - 9%.

During use, remove the fire extinguisher cover and manually spray PSB powder through a mesh onto the combustion area. The resulting stable powder cloud isolates air oxygen and inhibits combustion.

Powder fire extinguisher OP-10 (Fig. 3.5) contains PS-1 powder (sodium carbonate with additives) in a thin-walled ten-liter cylinder. It is supplied using compressed gas (nitrogen, carbon dioxide, air), stored in an additional 0.7 liter can under a pressure of 15 MPa. Used to extinguish fires involving alkali metals (lithium, cadium, sodium) and magnesium alloys.

Other fire extinguishers of this type use powder compositions: PSB (sodium bicarbonate with additives), PF (phosphorus-ammonium salts with additives), intended for extinguishing wood, flammable liquids and electrical equipment, SI-2 (silica gel with filler) – for extinguishing petroleum products and pyrophoric compounds.

New types of fire extinguishers.

Self-acting powder fire extinguisher (OSP) is a new generation of fire extinguishing agents. It allows you to extinguish fires with high efficiency without the participation ofperson. The fire extinguisher is a sealed glass vessel with a diameter of 50 mm and a length of 440 mm, filled with fire extinguishing powder weighing 1 kg.

Installed above the place of possible fire using a metal holder (Fig. 3.6).The fire extinguisher is activated within 30-60 s when the temperature in the area of its installation reaches 100 o C, and a pulsed release of fire extinguishing powder occurs, eliminating the fire in the protected volume.

|

Rice. 3.6. Fire extinguisher OSP-10 |

Self-activating powder fire extinguisher OSP-1 (Fig. 3.6) is designed for extinguishing fires organic solids, flammable liquids or melting solids, as well as electrical installations under voltage up to 1000 V, in small rooms industrial, warehouse and public purposes, as well as offices, cottages, garages, dachas, apartments. Advantages of OSB: fire extinguishing without human intervention, ease of installation, no operating costs, environmentally friendly, non-toxic, does not damage the protected equipment when triggered, can be installed in closed spaces with temperature conditions from minus 50°С to plus 50°С.The powder is easily removed from any surface. Guaranteed five-year service life without recharging and |

maintenance. Generators of volumetric aerosol fire extinguishing (SOT) – are the most modern fire extinguishing means. They are intended for extinguishing fires of flammable liquids and gases (gasoline and other petroleum products, organic solvents, etc.) and solid materials (wood, insulation materials, plastics, etc.), as well as electrical equipment (power and high-voltage installations, household and industrial electronics, etc.).

HFCs are not suitable for extinguishing alkali and alkaline earth metals, as well as substances that burn without air access. In HFO generators, the fire extinguishing agent is a solid aerosol of alkali and alkaline earth oxides. The use of the AGS-7 (SOT-1U) aerosol generator in the fire extinguishing system allows one to abandon the use of expensive equipment, which significantly reduces the cost of the system.

Rules for safe use of a fire extinguisher. Do not disassemble a fire extinguisher that is under pressure. It is not allowed to place fire extinguishers near heating appliances, where the temperature may be more than 50 °C, or in places with direct exposure to sunlight. Depending on the brand of powder used and the charge of the starting cylinder, inspection, technical examination and testing should be carried out in accordance with the manufacturer’s passport. When charging the powder, you should Special attention pay attention to its flowability and absence of lumps. All types of fire extinguishers must be labeled with the date they were last inspected. The tactical and technical characteristics of fire extinguishers are presented in table. 3.1.

Table 3.1

Tactical and technical characteristics of fire extinguishers

|

Type, brand of fire extinguisher |

Type of fire extinguishing agent |

Case volume, l |

Charge weight, kg |

Operating pressure of the cylinder, MPa |

Jet length, m |

Duration of action, sec |

Combustible temperature range,°C |

Average term service, years |

|

OU-2 |

CO 2 liquefied |

40÷+50 |

||||||

|

OU-5 |

Same |

15.0 |

40÷+50 |

|||||

|

OU-10 |

Same |

10.0 |

15.0 |

12.0 |

40÷+50 |

|||

|

OU-25 |

Same |

25.0 |

17.5 |

15.0 |

15.0 |

40÷+50 |

||

|

OU-80 |

Same |

80.0 |

28.0 |

15.0 |

15.0 |

40÷+50 |

||

|

OP-1 |

PSB powder, pyrant, etc. |

10.0 |

25÷+35 |

|||||

|

OP-5 |

Same |

15.0 |

50÷+50 |

|||||

|

OP-10 |

Same |

10.0 |

14.0 |

40÷+50 |

||||

|

OP-50 |

Same |

50.0 |

45.0 |

35.0 |

35÷+50 |

Fire fighting is a set of measures aimed at eliminating fires. D For the occurrence and development of the combustion process, the simultaneous presence of a combustible material, an oxidizer and a continuous flow of heat from the fire to the combustible material (fire source) is necessary; then to stop the combustion, the absence of any of these components is sufficient.

Thus, cessation of combustion can be achieved by reducing the content of the combustible component, reducing the concentration of the oxidizer, reducing the activation energy of the reaction, and, finally, reducing the temperature of the process.

In accordance with the above, there are the following main fire extinguishing methods:

Cooling a fire or combustion source below certain temperatures;

Isolation of the combustion source from air;

Reducing the concentration of oxygen in the air by diluting with non-flammable gases;

Slowing down (inhibiting) the rate of oxidation reaction;

Mechanical flame failure by a strong jet of gas or water, explosion;

Creation of fire containment conditions under which fire spreads through narrow channels, the diameter of which is less than the extinguishing diameter;

To achieve this, various fire extinguishing materials and mixtures (hereinafter referred to as extinguishing substances or extinguishing methods) are used.

The main methods of extinguishing are:

Water that can be supplied to the fire in solid or spray streams;

Foams (air-mechanical and chemical of different expansions), which are colloidal systems consisting of air bubbles (in the case of air-mechanical foam) surrounded by a film of water;

Inert gas diluents (carbon dioxide, nitrogen, argon, water vapor, flue gases);

Homogeneous inhibitors – halogenated hydrocarbons (freons) with a low boiling point;

Heterogeneous inhibitors - fire extinguishing powders;

Combined mixtures.

The choice of extinguishing method and its supply is determined by the class of fire and the conditions of its development.

Water, a steam-air mixture, an aerosol cloud, inert and non-flammable gases, chemicals, foams, fire extinguishing powders, and explosives are used as fire extinguishing agents. Water has a large heat capacity, cools the surface, and forms a film on the wetted surface of the burning substance that prevents the access of oxygen. When water is supplied in the form of compact jets, it is possible to knock down the flame and reduce the concentration of reacting substances in the combustion zone. For this purpose, use manual or fire monitors, which supply water to 70 - 80 m.

Compared to other means water has such advantages as wide availability and low cost, large thermal capacity, ensuring heat removal from hard to reach places, high transportability, chemical neutrality and non-toxicity. When heated from 0 to 100°C, 1 liter of water absorbs 419 kJ of heat, and when evaporating - 2260 kJ.

Extinguishing with water substances that react with it (potassium metal, calcium, calcium carbide, etc., magnesium, its alloys in a crushed state and mixtures of these metals with oxidizing agents, thermite-sodium, thermite-potassium and phosphorus-sodium incendiary substances ), not allowed. The use of water to extinguish live electrical equipment is prohibited.

When it comes into contact with hot metals, water does not decompose into oxygen and hydrogen, and does not form an explosive substance. flammable mixture due to lack of temperature. Thermal resistance of water is over 1700°C. You cannot extinguish burning gasoline, acetone, turpentine, alcohol, kerosene, fuel oil, lubricating oils, etc. with a stream of water, as these substances float to the surface of the water and continue to burn. These substances should be extinguished with sprayed water. When extinguishing ignited coal, it is prohibited to supply water from the barrels, because coal dust, raised by a stream of water under high pressure, forms an explosive mixture with air.

Foam- an even more effective extinguishing agent. It is lightweight and has enormous penetrating power. Foam is indispensable when extinguishing fires in large tanks with flammable liquids. The water is sinking in flammable liquid, and the foam covers the flame and extinguishes it. In the tank, foam can be supplied from both the top and bottom. Foam is used to extinguish fires in basements, holds, and engine rooms of ships. There are chemical and air-mechanical foam.

Chemical foam is obtained as a result of a reaction in which a gas is formed in a liquid medium. Typically, foam generator powder is used from aluminum sulfate Al 2 (SO 4) 3 - the acidic part of the composition - and sodium bicarbonate, NaHCO 3 - the alkaline part. When the powder is dissolved in water 1:10, as a result of the interaction of the acidic and alkaline parts, carbon dioxide is released and a foam is formed, which contains 80% CO 2, 19.7% an aqueous solution of Na 2 SO 4 with aluminum oxide hydrate Al (OH) 3 and 0.3% surfactant. Foam density is usually 200 kg/m3.

Air-mechanical foam is formed by mechanical mixing of air, water and surfactants. The composition of air-mechanical foam is 90% air and 10% aqueous foam solution.

Recently, high-expansion air-mechanical foam has been used. To prepare it, a foam generator is used, which sucks in a large amount of air.

It is prohibited to use foam to extinguish live electrical installations. When extinguishing flammable liquid fires, the thickness of the chemical foam layer is essential. The required thickness of the foam layer for oil, fuel oil, kerosene, gasoline is 20 cm. The required thickness of the layer air-mechanical foam for fuel oil, oil, kerosene, gasoline - 50 cm. This foam should be used to extinguish flammable liquids and gases.

water vapor used to extinguish fires in rooms with a volume of up to 500 m 3. Steam moistens burning objects and reduces oxygen concentration. The fire extinguishing concentration of water vapor in the air is approximately 35% by volume.

Inert and non-flammable gases(nitrogen, argon, helium) reduce the oxygen concentration in the combustion area and inhibit the combustion intensity. Inert gases are usually used in relatively small spaces. The extinguishing concentration of these gases when extinguishing indoors is 31–36% relative to the volume of the room.

Carbon dioxide, nitrogen, and flue gases are used to extinguish fires. Fire extinguishing concentration carbon dioxide in the air it is usually 30 - 35% by volume. Considering that this gas is heavy and spreads along the ground, its concentration in the lower part of the room will be higher, which contributes to effective fire extinguishing. But giving large concentrations of CO 2 is dangerous for people and uneconomical. Optimal quantity CO 2 supplied to the fire zone is determined by the oxygen content in the outgoing air stream. Typically, combustion stops if the oxygen content drops to 10–13%. Based on the physical characteristics of the gas and the nature of the development of fires, we can recommend the use of CO 2 for effective extinguishing in relatively small rooms in the initial stage of a fire, when the flames have not engulfed the entire room. Typically, carbon dioxide is supplied to the fire from railway tanks or cylinders.

Carbon dioxide (carbon dioxide) . When the air contains 12–15% carbon dioxide, the flame goes out, and at 25–30% the smoldering stops. Carbon dioxide is non-conductive and should be used to extinguish flammable liquids and gases, electrical equipment, and dusty materials.

It is prohibited to use carbon dioxide to extinguish fires of explosives, celluloid and substances containing magnesium. It must be remembered that the carbon dioxide content in the air (3–4%) has a toxic effect on the human body.

Carbon tetrachloride– a very effective means for extinguishing fires, since when the air contains 10% carbon tetrachloride and falls on a burning surface, approximately 145 liters of steam are formed.

The use of carbon tetrachloride gives rise to the possibility of the formation of phosgene, therefore, when extinguishing a fire, it is necessary to remove people from the premises and provide gas masks to the personnel involved in extinguishing.

Nitrogen is lighter than air, turns into a liquid state at a very low temperature (-195.8 ° C), so it is delivered to the fire area for extinguishing in special container vehicles. Typically the extinguishing concentration of nitrogen is 35% by volume.

The country has developed installations for burning various flammable substances (fuel oil, kerosene, etc.), products whose combustion after cooling are also used to extinguish fires. In this case, the O 2 content should be no more than 3%, CO - no more than 0.01%.

Chemicals stop or slow down the combustion process due to chemical inhibition of the intense oxidation reaction. For example, halogenated hydrocarbons (freons), introduced into the air, extinguish the flame due to the breakage of chains, radicals of the combustion process.

Fire extinguishing powders They are finely ground mineral salts with various additives. Fire extinguishing powders are versatile and can be used to extinguish various substances: solid and flammable liquids of various classes, metals and live equipment. The mechanism of the fire-extinguishing action of powders consists of inhibiting the combustion process by destroying active flame centers on the surface of solid particles or as a result of their interaction with gas-like decomposition products of powders. Powders are used for surface extinguishing, as well as in phlegmatization and explosion neutralization installations.

The most widely used powders:

PSB-3 powder(based on sodium bicarbonate) refers to powders general purpose. Used to extinguish flammable and combustible liquids, gases, electrical equipment, engines. PSB-3 powder is unsuitable for extinguishing smoldering materials, as well as alkali metals.

Fire extinguishing powders P2-AP, P-2APM ( based on ammophos) for general purposes have the same scope of application as PSB-3 powder, but in addition they successfully extinguish carbon-based smoldering materials (paper, wood, coal).

Powder Pirant-A and its modifications Pirant-AN, Pirant-AK are manufactured on the basis of phosphorus-ammonium salts. They are used to extinguish smoldering and solid combustible metals, flammable liquids, gases, and electrical installations.

P-4AP powder designed for volumetric extinguishing. Extinguishes flammable gases and smoldering materials in closed spaces. In order to stop combustion during volumetric extinguishing, it is necessary to create within a few seconds throughout the entire combustion zone such a concentration of powder at which its total surface will provide the necessary rate of elimination of active centers of the combustion reaction. This is achieved by supplying the powder with the required intensity and uniformly distributing it throughout the combustion zone.

Powder K-30 extinguishes alkali metals and titanium shavings burning in open areas. A necessary condition Stopping combustion when extinguishing with this powder is to cover the burning surface with a layer of fire extinguishing powder of a certain thickness.

The shelf life of most powders is at least 5 years. Temperature range of use from -50°С to +50°С

Methods and means of extinguishing fires are determined by the type of disaster, its level of complexity and related factors, such as the presence or absence of wind, proximity or distance to the flames of other buildings, the type of material fueling the fire and the degree of burning intensity.

Fire classes

Methods of extinguishing fires with standard and improvised means depend on the type and class of disaster.

Absolutely all fires have the following division according to the localization of areas covered by fire:

- spreading;

- localized.

The class division of fires takes into account what exactly is burning:

- “A” – contains two subtypes: with “A1” smoldering and smoldering substances are burning, with “A2” - melting but not smoldering materials;

- “B” – includes two subtypes: with “B1” non-dissolving flammable liquids and their vapors burn, with “B2” – dissolving ones;

- “C” – this includes all fires during which gases burn;

- “D” – characterized by the combustion of metals and contains three subtypes, depending on the characteristics of the burning metals;

- “E” – this class includes burning power plants, towers with high-voltage elements, wires with voltage present;

- “F” is the most complex type of fire, during which nuclear products, nuclear laboratories, radioactive substances, nuclear reactors and so on.

The fire at the gas station is class B1.

When a fire is signaled, even before arriving at the scene, rescuers try to determine the class of the fire and select the recommended extinguishing agents in accordance with this. Water is not always a suitable means of fighting fire, and spraying it from water cannons is not the only way to localize and extinguish a fire.

Fire extinguishing methods

Methods of extinguishing fires and types of fires are inextricably linked; accordingly, there are also several options for how to fight fire:

- cooling;

- dilution;

- insulation;

- suppression.

Cooling is the mechanical suppression of fire, reducing the temperature of burning substances. As a rule, pouring water, spraying water or dry chemicals is used.

Dilution involves the use of a fine spray of water vapor and jets, non-flammable gases and gas-water mixtures (AGW).

Isolation of the flame and its reduction to nothing is achieved through the use of powders, foams, combined compositions, making breaks in the burning material or an “explosive” explosion (for large fire areas), and foam is also used in this method. But this method of fighting fire also includes the use of various “improvised” means, that is, pressing the sunburnt grass with a blanket or trampling on a smoldering cigarette butt, this is also insulation.

Suppression is a technique for slowing down and stopping the chemical reaction that causes combustion. This effect is achieved by using powders or halide-carbon mixtures.

During practical fire extinguishing, several methods are used at once and combined fire-fighting materials are used.

Types and equipment for extinguishing fires

All fire extinguishing equipment, according to special literature, belongs to the following sections:

- Equipment designed to fight fires - all technical means, intended to prevent the spread, directly fight fire, protect people and material assets.

- The complete set of technical fire-fighting equipment includes hand tools, protective suits, specific “on-the-catch” devices in the equipment of fire-fighting vehicles, and so on. For example, a fire extinguisher hanging behind glass belongs specifically to this section.

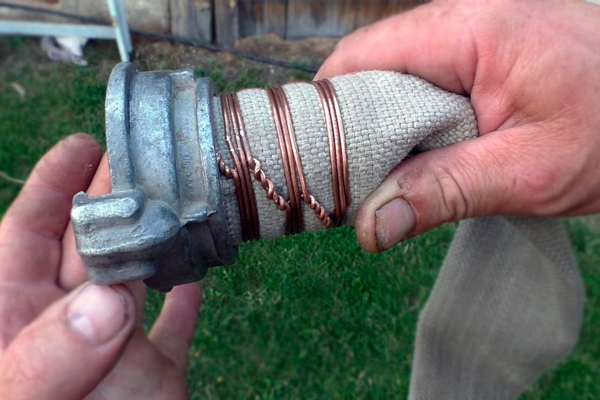

- Extinguishing equipment is direct communications that help firefighters. For example, sleeves, turrets, taps, trunks, branches and much more.

- Stationary installations – fire departments automatic systems, fire-fighting combined alarms and other means installed in the premises.

Minimum set fire equipment that can be used without having special training or practical skills in fighting fire, must be available wherever there is an increased risk of fire:

- in kitchens in catering establishments;

- near stages or performance areas;

- in places where various pyrotechnic displays are held and in other public spaces;

- in laboratory as well as specific production buildings.

Effective means at hand for extinguishing fires

The available equipment for fire extinguishing systems is not only a “blanket” or a “shovel”.

Such means include:

- fire extinguishers - hand-held portable devices for fighting fires;

- hydrants - a device for collecting water; in addition to the visible hinged part from the hose, the equipment has an underground or above-ground part connected to a source of water;

- PC, this abbreviation means permanently installed fire hydrants, which can be located both inside and outside buildings;

- alarms and automatic installations for extinguishing, detecting fires, transmitting signals about them to checkpoints firefighters and warning sound signal about mandatory evacuation from the building.

Fire extinguisher - improvised means to extinguish fire

Such means help to quickly extinguish a fire and prevent the fire from growing and spreading. Systems that prevent disaster should be everywhere, including city apartments and country houses.

Despite the fact that fire extinguishing systems, which are installed in buildings, have different characteristics and can themselves identify and extinguish fires, the simplest and most reliable firefighting PC still remains.

All the main methods of fire extinguishing before the arrival of duty crews boil down to the use of these types of fire extinguishing systems.

Sprinkler is a device related to fire extinguishing systems

PCs have different configurations, there are very simple options, providing fast and effective ways extinguishing fires of almost all types in their initial stages.

All stationary PCs must contain the following basic components:

- pin or pencil case with a key;

- the place where the pump is directly turned on or a remote point for starting it;

- rolled up sleeve;

- manual fire hydrant with valve;

- a barrel or “gun” with a flow power regulator is what is in the hands of the person extinguishing the fire.

The use of cranes includes all fire extinguishing methods, except for those fires during which electrical materials and structures with wires burn; water cannot be used to extinguish them.

In addition to the wall “cabinet” with the abbreviation “PC” and a number indicating the complexity of the configuration, the following systems are recommended for installation in buildings:

- automatic detectors that transmit a signal about the start of a fire and notify people with an alarm signal;

- stationary or modular automatic fire extinguishing systems.

As for the installation of systems that independently begin to extinguish a fire, they cannot be installed above electrical wiring, in buildings associated with electricity - nuclear power plants, electronics rooms, and so on. But there are also a number of other restrictions regarding the use of this type of safety systems, for example, in industries using gases and in other similar places.

Conclusion

All fire extinguishing methods are briefly divided into industrial, household and spontaneous. Such terminology allows you to quickly imagine what exactly you will have to deal with and, accordingly, be internally prepared for it.

All existing methods fire extinguishing is effective. Which method should you use? specific situation, depends on the totality of all the factors of the fire - what is burning, the speed of spread of the flame, the territory in which the fire occurred and many other points.

To increase the effectiveness of all fire fighting methods, it is advisable to install special detectors that monitor the space and instantly notify firefighters about the presence of a fire. They can and should be installed not only in public places, but also in apartments, country houses and in all other places where there is at least minimal risk of fire.