Plywood is a very accessible, relatively inexpensive material for various crafts. Things made from it can have not only decorative value, but also be useful in our everyday life.

Plywood is an easily processed building material, which is produced by gluing together several layers of veneer and specially treated wood chips.

Introduction

These sheets, which can be used for making crafts and structures, may differ:

- number of layers of veneer - three-layer, five-layer and multi-layer;

- the type of wood from which the multilayer sheet is made (deciduous or coniferous);

- according to the degree of processing (polished on one or both sides, not polished).

Building codes and standards

To learn more about the building material in question (about the classification of the entire plywood nomenclature, grades, standard sizes produced), which can be purchased for the manufacture of many products and crafts, it is recommended that you familiarize yourself with the following documents:

- GOST 3916.1-96 “General purpose plywood with outer layers of hardwood veneer.”

- GOST 3916.2-96 “General purpose plywood with outer layers of veneer coniferous species».

Schemes, drawings and patterns for products made from plywood sheets

Computer drawing programs

Today you can easily find a diagram, a pattern for a plywood structure, so that you can then prepare any drawing using computer-aided design systems (including the above cat pattern). Next, use a plotter to print it onto a paper sheet of the required format.

Drawing popular programs are the easiest to learn and can be used in 2D and 3D modeling, including for plywood structures:

- "KOMPAS" - complex automated systems, with the possibility of drawing up drawings in accordance with the standards of the ESKDI and SPDS series;

- AutoCAD is a two- and three-dimensional computer-aided design and drawing system.

So, if you cannot find a detailed drawing of the plywood product you need, then the application capabilities of the given software will help you make a full-fledged drawing using any diagrams and patterns posted on the Internet.

Kayak

The price of the construction plywood from which the kayak is made is simply incommensurate with the pleasure that the person who made it with his own hands and who loves rowing boats will receive.

The Eskimo kayak is the same kayak among the Aleuts - a traditional rowing boat of the Arctic peoples. This boat can be single, double or triple. Let's post drawings of a plywood kayak for one person.

The algorithm for building a rowing boat from plywood sheets is, in principle, general, with the exception of some nuances. Step by step order Actions for cutting, processing and assembling a kayak can be seen in the video in this article.

Plywood table - simple and functional

Clear drawings of a plywood table with your own hands, which will be easy to implement even for a person without special carpentry skills and experience.  Table cover (1 sheet) - 1300 x 600 x 16 (mm)

Table cover (1 sheet) - 1300 x 600 x 16 (mm)  Inner wall (1 sheet) - 1170 x 400 x 16 (mm)

Inner wall (1 sheet) - 1170 x 400 x 16 (mm)

Plywood constructor

Various drawings plywood construction kits are now gaining more and more popularity. Assembling such models from safe material is a very useful activity for children and teenagers. Such crafts will become good examples of collections and will decorate the modellers' corner.

Tank

The stages of work on installing a tank model are as follows:

- The plywood is sanded (first with medium-grain sandpaper and then with fine-grain sandpaper);

- The drawings are carefully transferred through carbon paper onto sheet plywood material sanded with fine-grained abrasive.

- In the corners of the contour transfer, through holes are drilled with a drill (drill 3 mm or more);

- Attach the file to the jigsaw and start cutting out the elements of the tank;

Note!

Cutting out parts must begin inside the contours of the tank blanks, and only then around the office itself.

Advice!

When assembling the model's plywood assemblies, have different types of needle files on hand so that you can fit the elements together at any time.

- After adjusting all the parts, you can start gluing them (for example, with PVA glue, “Titan”);

Advice!

In order for the components and elements of the tank to grip each other more firmly and reliably, you can tie them with thread or rope for a while after gluing them.

- The cannon can be made by cutting the wooden handle of a watercolor brush or from other auxiliary material;

- If desired, you can apply a side number or other inscriptions and patterns to a tank, or any other model, using an electric burner;

- For greater preservation and decoration of the model, they can be coated with varnishes and paints.

Car – retro (old Mercedes)

Note!

When you transfer these drawings of a plywood machine with your own hands onto the plywood sheets themselves, do not forget to transfer the numbers.

When assembling the model itself, look carefully at the numbers.

IN in this case the process is carried out according to the following algorithm, in accordance with digital notations:

- the part or assembly numbered 1 must be connected to another number 1;

- and part number 2 is attached accordingly to the next number 2 and so on until the machine is assembled.

Gun

Drawings of a pistol made of plywood model "Bulldog". When assembling, we follow the same rules as when assembling a machine: the same numbers must be mounted with each other.

Advice!

This model of pistol is best coated from a bottle of spray paint; for a better resemblance to the original, layers of black paint can be applied.

Dinosaur

When designing, drawings of plywood dinosaurs, for example, those presented below, can be made in any scale you need according to the presented pattern in a drawing program for a computer.

Preparing the material, model elements and the assembly itself is not difficult, but you will have to have some patience when working with a jigsaw and adjusting the model components to each other.

Napkin holder – “Grape leaves”

This item is in the form grape leaves always useful in the household for its intended purpose - for napkins, and for storing, for example, sheets of paper of the selected format:

Vase, stand for pencils, pens, brushes

Drawings of a plywood vase, from which you can easily cut out a craft of the size you need:

Plywood panel

It is the ease and simplicity of cutting with a jigsaw from plywood sheets of various configurations with different sizes, installation from them various designs, allows you to perform a variety of decorative panels for the walls of our home. Any panel made carefully is an excellent gift for family and friends.

Drawings of a plywood panel, which also serves as a shelf in the household:

Some useful tips and warnings:

- When transferring patterns and drawings onto plywood, use the thinnest and sharpest pencil lead. It's even better to use a used ballpoint pen, then the lines will always be the same and the copy paper won't be torn by the ballpoint. It is convenient to transfer drawings to plywood using a laser printer.

- For better fastening of parts, where possible, it is recommended that the width of the grooves correspond to .

- There are two types of files with large and small teeth. It is more convenient for beginners to learn how to use a thick file, and cut out small parts with a thin file, already having some experience and skills in using a jigsaw.

- The files must cut from top to bottom, so Special attention pay attention to correct fastening files in a jigsaw.

- Files can easily break, so cut carefully and do not allow parts to hang on the saw blade.

- When purchasing a file, make sure that the teeth are sharp, and that the file itself should not bend easily, but rather be firm. It’s not the flat ones that are easy to use, but the so-called “twisted” files – they can be used to make cuts in any direction.

- For those who enjoy cutting out structures from plywood sheets as a hobby, there is no need to purchase a band saw; it is enough to purchase a jigsaw. Although everyone is an amateur, some craftsmen still often resort to a hand jigsaw when they “need to get a feel for the material.”

conclusions

- Before choosing, purchasing and directly working with the material from which you will cut models, panels, construction kits and structures, familiarize yourself with its types and classification according to construction documents (GOST).

- For sawing, purchase high-quality tools, equipment and accessories for it.

- Take a responsible approach to choosing high-quality plywood. Don't limit yourself to a visual inspection, tap it for internal voids and delaminations due to poor gluing of veneer layers.

- Before working with a jigsaw, optimally equip your workplace. Pay special attention to good lighting so that the cut and markings are clearly visible and your eyes don’t get tired. It’s not a bad idea to use a strobe light to illuminate the area where you’re working with a jigsaw. Convenient and comfortable sawing!

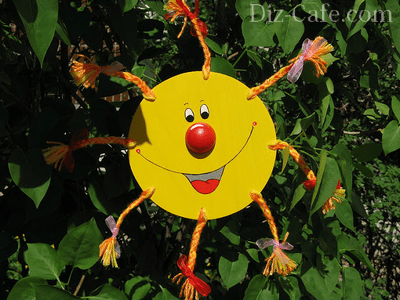

How nice it is to stroll through your own garden, enjoying the enchanting nature and stunning fresh air. When thinking through the design of a country plot, each owner tries to make it special by adding color and creating a positive mood. Garden figurines made of plywood can successfully complement plant compositions and amazingly transform the area, making it a nice and cozy corner conducive to a pleasant rest. Anyone can make such funny figures from plywood. To create such a decoration, it is not at all necessary to have the skills of an artist; you just need to show your imagination and put in a minimum of effort.

Such figures are designed to emphasize certain places on the site, making them more elegant and attractive. Thanks to their natural nature, decorations made of wood and plywood fit most harmoniously into landscape design.

Figures cut from plywood garden plots look extraordinary

You can make many interesting functional decorations for your garden using plywood. It can be:

- Funny figures;

- Containers for flowers;

- Bird feeders;

- Decorative fences.

There are a great many options for plywood figures, and each of them is distinguished by its originality and expressiveness.

Miniature toy houses, animal figurines, whimsical fairy-tale sculptures and cartoon characters decorate many suburban areas today

Plywood is one of the lightest and most convenient materials for creating crafts. It is so easy to work with that figures can be made from it quite quickly, and most importantly, it is interesting.

Plywood is sheets of wood veneer fastened together in several layers using glue or a synthetic compound. The strength and thickness of the material directly depends on the number of these layers. The thickness range of plywood sheets ranges from 3 to 30 mm. The material can have a completely different texture, which can affect the color and structure of the finished craft. For example: thanks to its beautiful structure and warm shades, birch plywood looks very aesthetically pleasing, while coniferous plywood is more suitable for painting.

For creating garden decorations, sheets of plywood are excellent, the material for which was: poplar, alder, aspen, pine, birch, spruce

The main advantages of plywood:

- Environmental friendliness;

- Strength and durability;

- Waterproof;

- Good flexibility;

- Compatibility with other materials;

- Ease of processing.

But since plywood is still a tree, which by its nature is susceptible to environment, when choosing a material, a number of points should be taken into account:

- Moisture resistance. To decorate outdoor spaces and decorate your backyard, you can use plywood sheets marked FKM and FSF. In their production, melamine and phenolic resins are used, which have a moisture-repellent effect.

- Sanded finish. On sale you can find sheets that are sanded on one side (Sh1), processed on both sides (Sh2) and not sanded at all (NS). This point is very important only when you do not have time for additional processing.

Oil and oil paints are ideal for creating expressive and colorful garden decorations. acrylic paints. They fit perfectly on wooden surface, creating rich color combinations. The paints are resistant to ultraviolet rays, maintaining their attractiveness for several years.

When choosing materials for making jewelry, it is important not only to pay careful attention to the quality characteristics of plywood. It is also important to choose paints for decoration that will maintain color saturation for several seasons.

We create figures with our own hands

Most often, dachas are decorated with flat figures cut from moisture-resistant plywood sheets. To create an original decoration we will need:

- Moisture-resistant plywood 2 cm thick;

- Stencil;

- Jigsaw;

- Simple pencil;

- Fine-grained sandpaper;

- Screwdriver and screws;

- Acrylic paints, brushes and varnish.

If you plan to install the figure without resting it on any support in the garden, you must also consider making pegs for its base. Their size depends on the dimensions of the figure itself. But, in any case, expect that the pegs should go at least 50 cm into the ground.

We invite you to remember a forgotten form of creativity - sawing with a jigsaw, making an unusual decoration for the garden with your own hands

You can decorate any corner in the garden with a plywood figurine, hanging it on a rope, fixing it to a support with nails and placing it on stands.

You can also make a stencil for making a figure yourself. To do this, you need to draw the design you like on a sheet of paper, formatting it in the form of a drawing or silhouette, and then simply cut it out.

Master class #1 – curious snail

This cute plywood figurine is so easy to make that anyone can make it. Little helpers will happily respond to adults’ invitation to participate in the exciting process.

The charming snail will surely appeal not only to little fidgets, but also to adult guests of the site, becoming an elegant decoration for the playground and a favorite character in exciting games.

On a sheet of paper we make a sketch of the future figure, the image of which is subsequently transferred to a plywood base

If you are confident in your abilities, you can do without a paper template by drawing a snail directly on a sheet of plywood. For safety reasons, you will have to do it yourself when cutting out the shape with a jigsaw. But you can safely entrust the drawing of the contours and coloring of the snail to impatient little helpers.

Using a felt-tip pen or burner, we draw the contours of the snail so that even after covering with paint they remain bright and expressive

We paint the blank with acrylic paints, choosing spectacular contrasting combinations. To obtain rich colors, acrylic paints are best applied in 2 layers

The snail is ready. Let the paints dry a little, and you can safely plant the cute character in any place you like in the garden.

Material on how to make it will also be useful garden figures for a do-it-yourself garden:

Master class #2 – charming Scarecrow

By allocating just a couple of hours of free time to make the Scarecrow, you can make a funny figurine with your own hands that will bring a touch of sincerity and warmth to the site.

This incredibly cute and charming fairy-tale character Scarecrow from the fairy tale “The Wizard of the Emerald City” can live on your property

We will make the figurine in several stages. First, we take a sheet of plywood, onto which we apply the outline of the future character using a stencil. The finished drawing can be transferred to plywood using regular tracing paper.

If we make a figure that will rest on pegs, we immediately attach them. To do this, we drill paired holes in the body of the figure, the diameter of which corresponds to the size of the pegs.

Using a jigsaw, cut out the shape along the outlined contour. We carefully sand its edges with sandpaper, giving them smoothness.

We design the figure: we draw the elements of the character on the blank with a simple pencil and paint them with acrylic paints

Having painted the front part of the workpiece, we paint the end faces. When the paints have dried, coat the figure with varnish.

To decorate the figure, we used dried grass to decorate the scarecrow’s hair, a button and a satin ribbon to make the character’s collar.

Our cute fairy tale character is ready. All that remains is to stretch the wire through the holes in the hat and secure it to a tree branch or fence.

A little secret: if during cutting with a jigsaw a sheet of plywood begins to delaminate, it is necessary to saturate it with a solution prepared from PVA glue and water, taken in a 1:1 ratio. The plywood is impregnated 2-3 times, applying each subsequent layer after the previous one has completely dried.

Since such crafts turn out to be quite light, the finished products should be securely fixed, partially buried in the ground, covered with sand or glued to the base.

Using the same principle, you can make themed plywood structures, for example: a miniature fairy-tale forest with fancy trees lost in a flower garden or a pretty clearing by a pond filled with funny figures of animals. Do-it-yourself plywood structures will decorate your site, making it attractive and unique.

This article will help readers who want to try their hand at furniture design. We suggest starting experiments with making furniture from plywood. The article provides examples of popular works by famous designers, shows the basics of plywood processing, as well as making a rocking chair with your own hands.

Imagine the interior of your dreams, which reflects your individuality, emphasizes your character traits and status. Modern trends in interior design mostly lean toward non-mass design items, but rather, designer-made ones. However, there is an opinion that designer furniture has a very high cost and is often simply unavailable.

Factory-made furniture often does not meet individual preferences - it is simple, ordinary and typical, not always different high quality and often quickly loses its original appearance. The “advantages” of factory-made furniture include a rather trivial design. As a result, every apartment with factory furniture is often an example of unattractive urban design. But I want something special and original.

Gothic leather furniture in the best traditions of post-art nouveau, designer Michael Haillard, France

Gothic leather furniture in the best traditions of post-art nouveau, designer Michael Haillard, France

There is a stereotype regarding designer furniture; it is associated with furniture made from expensive solid wood with luxurious leather trim. That’s how it is, but is it necessary to limit creative thought to such rigid boundaries, because the author’s work presupposes, first of all, an idea that can be realized using various materials.

It is worth noting that heavy classic furniture has practically left the fashionable furniture Olympus with the exception of the works of several fashion designers, including the luxurious “animal” furniture of Michael Hallard. In turn, minimalism, which has led the furniture TOP, requires a completely different design approach, which also involves other materials for manufacturing.

Recently, in search of inexpensive materials for making furniture, designers have paid attention to such simple and familiar plywood. Although plywood has long been used in the manufacture of furniture, various structural models are made on its basis; it is valued for its “ability” for absolutely fantastic transformations with relatively simple technological processing. At the same time, designer furniture made from plywood has a more affordable price than furniture made from solid wood.

Author's coffee table, designer Justin Couch, France

Author's coffee table, designer Justin Couch, France

In the world of furniture design, there are famous names of designers who have made a name for themselves by making furniture from plywood. Their works became the prototype of industrial designs, which are deservedly popular among lovers of modernism; there are also samples that are made only by hand.

Designer fantasies in fashionable furniture interpretations

Almost every person is attracted by completely informal furniture solutions from fashionable Western designers. Worldwide author's design is developing in a completely different creative plane than industrial. In this creative space, the idea becomes part of the philosophical vision of the world, and the courage of the designer’s thoughts is elevated to a cult. There are no rules, much less prohibitions. Even functionality fades into the background. the main task designer furniture - to delight consumers with its informal forms.

Left: Restaurant decoration with plywood, New York. Right: chair made from bent plywood elements

Left: Restaurant decoration with plywood, New York. Right: chair made from bent plywood elements

Many people wonder what creativity is? In this case, the creative approach only partially conveys the meaning of this quality of artists. Creativity is the ability to rethink reality, create some creative idea, often understandable only to him, and embody it, at first glance, in a trivial everyday object. Only a few original works have become the basis for industrial designs that successfully combine the main characteristics of factory furniture: ergonomics, functionality and technological ease of manufacture. The remaining models have become real examples of modern art.

Left: Floral furniture designs by Shige Hasegawa, Japan.

Left: Floral furniture designs by Shige Hasegawa, Japan.

Right: Sunny plywood ottomans upholstered in dyed fur from Kyle Bunting Furniture & Art

Modern technologies Furniture production has not undergone significant changes in many respects. Furniture is made in almost the same “old-fashioned” way as several centuries ago, and plywood is considered one of the most used furniture materials.

Examples of Dressler brothers furniture, Canada

Examples of Dressler brothers furniture, Canada

Simplicity of manufacture, sophistication, minimalism and the peculiar delicacy of plywood furniture samples due to the use of many carved parts fastened together - lamellas - allow you to take a completely different look at a seemingly trivial furniture material.

The modern pioneers of plywood in a new incarnation were the Dresler brothers (Jason and Lars Dressler). To make their elegant, minimalist furniture models, they use high-quality birch plywood, which is cut on a special woodworking machine; processing, namely: sanding the elements, subsequent polishing, painting and final assembly, is done by hand.

The ease of making lamellas from plywood and the possibility of producing highly decorative furniture models have led to various design experiments. An example is the original work of American designer Justin Couch, who uses contrasting applications made from cut plywood coated with acrylic putty.

Left: designer bench made from plywood slats. Right: Justin Couch coffee table

Left: designer bench made from plywood slats. Right: Justin Couch coffee table

Justin Couch uses two types of plywood - birch for light parts, walnut for blackened parts, this approach makes painting easier. His furniture is informal, elegant and extraordinary. Justin Couch's portfolio includes both exclusive designer models and products designed for mass production.

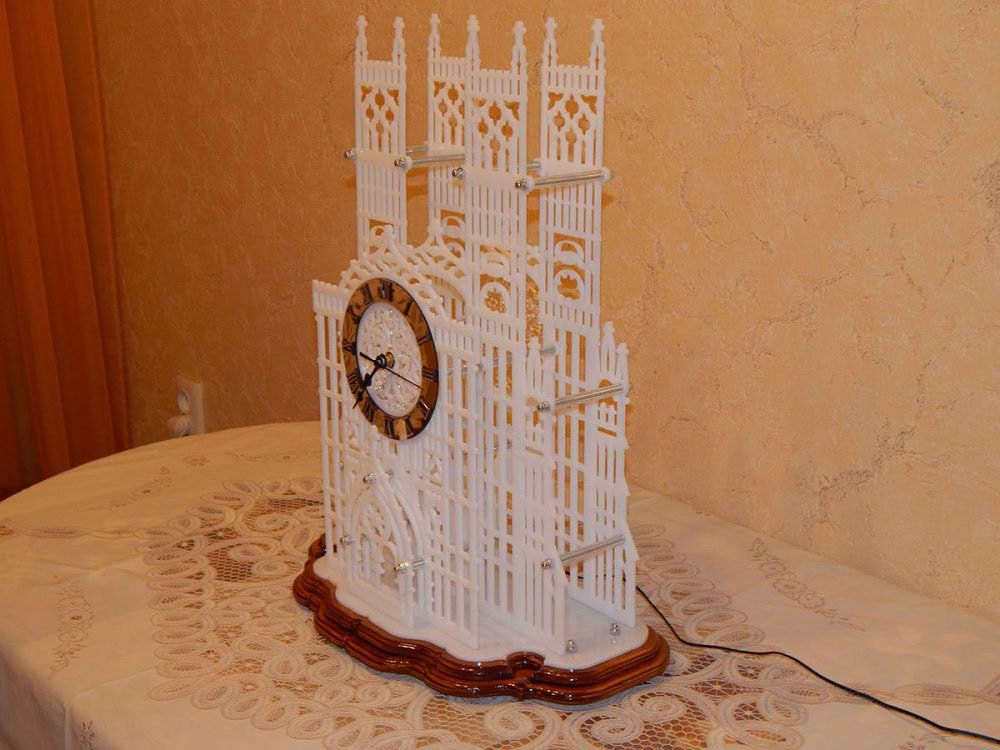

To some extent, the path of Justin Couch was repeated by the American designer Hilary Wiezbenski, who founded small company and produces designer furniture from plywood. She started by selling leaf tables. Over time, Hilary began experimenting with bent plywood. Inner admiration is evoked by the original shelf with a “flowing” clock, made entirely by hand from steamed plywood.

Left: Leaf table, designer Hilary Weisbensky, USA. Right: shelf with “dripping” clocks

Left: Leaf table, designer Hilary Weisbensky, USA. Right: shelf with “dripping” clocks

Plywood is universal, it can be used for making furniture, in interior design and allows you to achieve stunning effects and textures.

Left: Justin Couch's industrial model of a rocking chair.

Left: Justin Couch's industrial model of a rocking chair.

Right: plywood bedside table by the famous American modernist George Nelson

Author's models of plywood furniture

Most foreign design studios do not supply their products to Russia. Although delivery is possible, it often involves many difficulties. What to do if you want to decorate your home in a non-standard way and have a little free time and desire? The answer is simple, you can try to make furniture with your own hands. This is possible and, it turns out, not so difficult. The technology for processing plywood is quite simple, but we will talk about this later, and now we will pay attention to designer furniture models that you can try to make yourself.

Designer sun lounger for the garden and terrace

The original chaise lounge was created by the design company DesignKoalition. A sun lounger will provide you with maximum relaxation and relaxation in the fresh air. The base for the chair is made of plywood with a thickness of 18-21 mm, the guides are rigidly connected to each other wooden beams or metal pipe.

University lounge chair SOFT Rock

The University of Massachusetts developed an original chaise longue, which has become a real decoration of the university grounds. The chaise longue is made of flexible plywood, with a LED lights which is powered by solar panels. The interior of the chaise lounge, designed for relaxing, reading and studying, has excellent ergonomic properties.

Coffee table by Jeffrey Matthias

An interesting and simple table to make was proposed by American designer Jeffrey Matthias from Denver, a specialist in the field of industrial design. On his website you can see his portfolio, which includes drawings of products for making furniture yourself. The main quality of industrial plywood products is the most economical cutting of the plywood sheet, which is exactly how this table was designed. Jeffrey enthusiastically communicates with everyone who wants to reproduce his furniture models and asks to write to him with any questions that arise.

Children's tree table made of plywood

If you want to customize your children's room in a green design style, we recommend reproducing this model desk-tree. The table is made of plywood, the edges are treated with a special acrylic putty, which allows you to achieve the effect of plastic. The result is an extraordinary children's desk and chair with a vibrant finish. The table is made of plywood 24 mm thick.

Model of a children's desk in the form of a tree (90x140x75)

Model of a children's desk in the form of a tree (90x140x75)

Justin Couch Coffee Table

An interesting element in the living room will be the wonderful coffee table by Justin Couch in the modern baroque style. To achieve a similar “varnish” effect, special acrylic putties are used, which make the surface look like plastic.

Dresler brothers chairs

Of course, an exceptional example modern furniture The Dresler brothers' sun loungers are made from plywood. Such products are easy to manufacture; the only difficulty will be in the manufacture of lamellas. However, the result in the form of ready-made armchairs will add a special note of fashion to your interior.

Dresler brothers chair. Assembled from lamellas that are pulled together

Dresler brothers chair. Assembled from lamellas that are pulled together

Rocking chair by Toby Howes

Toby Hoves is a well-known furniture designer in Britain, his designs are distinguished by sophisticated elegance. They are excellent examples of contemporary furniture modernism. His portfolio includes a rocking chair made of bent plywood. Many craftsmen find it difficult to replicate such a chair. It is obvious that the plywood in this case is processed by hand.

Plywood table by Erwin Zwiers

The tabletop in this model is unique. It is made using twisted sheets of thin, flexible tropical wood plywood. Agree - the table is non-trivial and easy to make.

The success of the bench-chair is associated primarily with its exquisite ergonomic shape. Such chairs become an element of children's rooms, public spaces and ultra-modern living rooms. For manufacturing, lamellas are cut out and rigidly fastened together. The result is a stable and lightweight structure.

Chair-bench DieFabric. Drawing of slats for a chair

Chair-bench DieFabric. Drawing of slats for a chair

The legendary Asterisks watch by George Nelson

It is impossible to ignore the masterpieces of the famous American modernist George Nelson. Asterisks watches are especially popular among its models. Like everything ingenious, they are easy to make and can become part of your interior if you make them yourself from thick plywood, cover them with acrylic putty and, for example, yellow paint.

Technology for making furniture from plywood

Plywood is widely used in the furniture industry; it is used for the manufacture of structural and decorative parts. Plywood boards are characterized by high strength and elasticity, which allows them to be used in various furniture designs, which as a result also have a small weight.

Plywood grades and safety of use

You can find several types of plywood on sale, the most common in our region is birch plywood; other varieties can be imported from other countries. In general, plywood is divided into 5 grades, and sanded and unsanded plywood are also distinguished:

- FOF is a moisture-resistant laminated plywood, covered with a special layer of PVC film to provide additional moisture resistance.

- FSF is a moisture-resistant non-laminated plywood, usually birch, that is exceptionally waterproof. This is plywood with a wide range of applications, it is also used as a furniture material; phenol-formaldehyde glue is used for its production.

- FC is birch plywood produced using urea-formaldehyde resin.

- FBS - bakelite plywood, also called “marine” or “Finnish” plywood. This plywood is coated with bakelite varnish, which gives it special physical and chemical characteristics. Bakelite plywood does not change its performance under the influence of hot climate, moisture and sea water.

There has been debate for a long time regarding the safety of using plywood in furniture production. For example, FSF plywood is made using resins with phenolic compounds, while FC uses urea (ammonia). According to GOST, only formaldehyde content is regulated. The question arises, what is the emission of formaldehyde and what level is safe? IN plywood FSF Less emissions mean it's safer.

All Russian plywood factories have an E1 safety certificate; plywood that meets the E0 certificate is available on the market; some factories are also certified to the “safer” CARB 1 and CARB 2 standards.

From the point of view of furniture safety, it is better to avoid Chinese plywood and opt for Finnish manufacturers who strictly comply with the requirements of the standards, and Finnish resins contain a minimum of formaldehyde. When choosing plywood for a nursery, you should also avoid laminated products that contain a high level of formaldehyde. Experience shows that the issue of environmental quality of plywood from various manufacturers is quite controversial.

The cost of plywood can vary depending on the type, manufacturer, and wood species used for its production.

Marine grade mahogany plywood. Marine plywood made from gaboon tree veneer (Acuomea Kleinea), native to the Congo, can be sourced from factories in Holland, Italy, Greece, France, Israel and the USA. A variety of this type of plywood is plywood made from the veneer of the Shorea tree, native to the Philippines, such plywood is more common under the names "meranti" and "luan", commercial grades "yellow luan", "white luan", "red luan" are also available. and "red meranti". Typically this plywood comes in a thickness of at least 6.2mm, and the okume grade can be found in thinner sheets. The sheet size often does not exceed 1.22x2.44 m.

Plywood made of birch, cedar, beech, pine. As a rule, this is plywood with a wide range of applications, made from available wood in the country of origin. It is this kind of plywood that is most often used for making furniture; plywood with a beautiful decorative coating is especially valued. Good stuff Russian plywood is used for making furniture; in many cases it is not inferior to foreign analogues.

Birch plywood

Flexible tropical wood plywood. This is an excellent option for making bent parts. Flexible plywood made from ceiba wood is highly valued, as well as keruing and wiga. During the production of flexible plywood, special qualities are given to it; any parts will have structural strength and will be self-supporting. This plywood was created specifically for design purposes. Ultra-light plywood has also been developed from ceiba and sumaum wood, which is almost 2 times lighter than its analogues. Tropical plywood is highly decorative; when coated with stain, its texture can be comparable to Wenge veneer, which is the most popular in furniture design.

Laminated plywood. This is a type of plywood that has surface layer laminate For furniture production, laminated plywood with various finishing colors is used.

Plywood processing

Making furniture from plywood does not require significant professional training. Some furniture samples can be made using a jigsaw, router and drill; more complex parts can be cut on a CNC woodworking machine. Bent parts will be difficult to manufacture.

There are several ways to produce bent parts. The first method is to steam the plywood blank. This applies to traditional types of plywood, which do not bend. In the simplest case, the plywood blank is placed in a hot bath, where it is kept for about 30 minutes; while hot, the blank must be secured to the mold and left for 5-7 days. This method requires careful bending.

Method for manufacturing a curved blank

Method for manufacturing a curved blank

You can make a bent blank from several thin sheets of plywood and give it the required form. In this case, flexible plywood made from tropical wood is used. To fix the mold, epoxy glue is used, which is applied on both sides of the workpiece. The glue is absorbed into the top layer of plywood, polymerizes and then retains the given shape of the furniture part. Gluing plywood is done using ordinary carpentry glues - bone and flesh glue, casein glue do not use, as it leaves streaks. You can use glue made from synthetic resins.

Decorative ideas for plywood furniture

The shape of the furniture is not always self-sufficient; the design also involves a color scheme. In some cases, shape and color are dominant, such as in the Dresler brothers' chairs. British designer Erwin Zweers emphasizes the natural beauty of wood, and Justin Couch completely covers the wood texture with paint.

When making designer furniture, you can pay special attention, first of all, to painting the furniture using the decoupage technique. Here are several options for decorating furniture using this technique.

A wonderful pale pink plywood cabinet will add a unique flair to a young girl’s room. At first glance, the exaggeratedly simplified shapes of the cabinet are complemented by bright color scheme, which distinguishes this model from trivial industrial solutions.

Looking at this cabinet, you unquestioningly agree that the author’s design creates a special world around its owner. Latex paints and varnish were used for painting.

The plywood bureau, decorated in a botanical style using the decoupage technique, is very original. A whole series of furniture designed by the Martha Stewart Living design studio is made in this style. Floral motifs look very harmonious, and decorating furniture in this style is quite simple - the base is covered with primer, then a blank with a pattern is glued, and then varnished.

Martha Stewart Living Design Furniture Series

Martha Stewart Living Design Furniture Series

A luxury mahogany cabinet cabinet can be made from meranti plywood. Light areas are decorated using decoupage technique.

Wardrobe FLORA by Joseph Frank Design

Wardrobe FLORA by Joseph Frank Design

Instructions for making your own rocking chair

You can make furniture yourself, and it’s even easier to find a use for it. Even a not entirely successful first copy will decorate the interior of a dacha or terrace; in addition, some shortcomings can be hidden by painting or using textile decor. You can start your first experiments by making a rocking chair; it turns out it’s quite simple.

To make such a chair you will need desire, a little skill, affordable woodworking tools and plywood measuring 1520x800 mm and thickness 4, 10 and 15 mm.

At the first stage, the patterns of the chair parts are drawn. The pattern can be made by transferring the drawing onto cardboard with a cell size on a scale grid of 100x100 mm.

The drawing of the part is transferred to plywood and cut out with a router. It is necessary to arrange the parts in such a way as to perform the most economical cutting. For production you will need 3 sheets of plywood 15 mm thick. At the fastening points, holes are made for screws.

All cut parts are carefully carefully sanded and sanded with sandpapers of various grain sizes, only then the product is assembled. Typically, priming and painting are done disassembled. If it is necessary to check the functionality, the chair is pre-assembled.

The back of the chair and the seat are assembled from plywood strips, which are glued onto thin plywood 4 mm thick (parts 10-11). This results in a flexible backrest design. Parts 4-7, 8 and 9 are made from three sheets of plywood. Technologically, we recommend gluing together three sheets of plywood and only then cutting out the part.

Table. List of parts and materials

| Part no. | Name | Qty | Dimensions | Materials |

| 1 | Sidewall | 2 | see fig. | plywood 15 mm |

| 2 | Rack | 2 | — | — |

| 3 | Seat support | 2 | — | — |

| 4 | Plank | 1 | 470x45 | — |

| 5 | Plank | 1 | 540x45 | — |

| 6 | Plank | 1 | 485x45 | — |

| 7 | Plank | 1 | 470x45 | — |

| 8 | Seat bar | 16 | 540x30 | plywood 10 mm |

| 9 | Back strap | 18 | 500x30 | — |

| 10 | Back base | 1 | 540x500 | plywood 4 mm |

| 11 | Seat base | 1 | 540x480 | — |

| 12 | Step | 1 | length 535 mm, diameter 28 mm | Beech, birch |

A little effort and you can show off your chair self-made, perhaps this will be just the beginning, and you will have a new hobby that will also save your family budget. The simplicity of making furniture from plywood is truly surprising; it can also be achieved by women, who are always able to create something special from simple and uncomplicated things.

The variety of furniture options that can be made from plywood causes slight admiration for any person who does not even plan to engage in self-production furniture. Indeed, plywood is excellent design material, which not only professional cabinetmakers can work with. Making furniture with your own hands is accessible to almost every person who wants to try their hand at furniture design. Moreover, you can use the “tips” of fashionable furniture designers working with plywood, or create something of your own.

An electric jigsaw is used by home craftsmen to create beautiful products from plywood and wood. Such crafts are used for a variety of purposes. They can be decorative or serve as household items. Every home craftsman who is interested in this activity should know the features of working with the tool.

You should learn more about how to use the “miracle jigsaw” and what can be cut with it.

Subtleties of working with a jigsaw

A jigsaw is a universal device that is used for cutting shaped products from various materials. All you need is to choose the right canvas. It is important to understand how to cut out shapes complex shapes. Many novice craftsmen need to figure out how bevels on boards and various components of crafts are made. Electric jigsaws work best when cutting softwood. However, the thickness of the elements from which cutting is performed should not exceed 3.8 cm.

Blades that will be inserted into a jigsaw quite often bend and leave beveled edges. A straight cut is usually achieved with a well-sharpened blade. However, you should not put too much pressure on the tool while working.

You should first start the saw at the highest speed, and then select the blade angle. This will result in fewer chips. In materials that are highly brittle, it is necessary to drill holes. This will allow you to saw off the workpiece without unnecessary risk. As a result, there is no chipping of the part.

To ensure fast cutting, coarse blades should be used. However, it should be taken into account that when choosing such consumables, it will be more difficult to sand them later. Blades for electric jigsaws are made in such a way that the cut is made when the blade moves upward.

Choosing the Right Blade

Choosing a blade for an electric jigsaw is a major consideration when cutting wood and plywood. Often a jigsaw lies idle in a home craftsman's household. However, when you need to make a complex pattern, this tool is more necessary than ever.

Quite often, an electric jigsaw is used as a tool for cutting a hole in a countertop or when installing a kitchen sink. This tool is also used for cutting metal. When using other saws, it is often impossible to complete the assigned tasks. A jigsaw is a universal device. Both beginners and experienced home craftsmen can work with it. As a result, you can get excellent results using different materials - plastic, wood, plywood.

How to use the tool

A jigsaw is used for a variety of tasks. Its main function is to cut curved shapes into wooden products. Getting smooth curves using this tool is quite easy. The base of the tool should be kept level on the workpiece. When the preparation is completed, you can begin the main work. Then the engine is turned on and the device is slowly moved along a pre-marked line, at a distance of 2 mm from it. Fine sanding is done later.

The saw should be moved at such a pace that the blade can easily cut through the material without any deflection. A jigsaw works great when cutting boards crosswise. A stop must be used if a perfect cut is required. Bevel cuts are fairly easy to make using a jigsaw. Before work, it is necessary to firmly secure the workpiece.

If an oblique or vertical cut is performed, the distance between the blade and the fence is set to the same as on circular table. If you need to make a precise and long cut, it is difficult to work with a jigsaw. In this case, first use a circular saw. The final cutting of the element is performed with a jigsaw. It must be pressed firmly against inside marked line.

Where to start

First, the workplace is properly organized. Fulfilling this condition is especially important for high-quality cutting. If the space is arranged correctly, work will be convenient and comfortable. This condition is necessary to create a quality product.

The thrust structure is a special machine. People call it “swallowtail”. This table is made from rectangular boards. It has a wedge-shaped incision that extends into the working area. Dovetail attached to the edge of the table.

An electric jigsaw can be used while standing or sitting. The workpiece should be located at a distance of 40 cm from the eyes. It is necessary that the lighting lamp be installed in front of the master. It is placed at an angle to the surface.

Tool preparation

The saw blade in a jigsaw must be fixed in a strictly vertical position. The teeth should point down. Before work, you need to stretch the fabric well. The degree of tension must be adjusted by compressing the frame. The device must be rested against the edge of the table. Then you should tighten the lambs with pliers. When straightening the frame, the canvas will stretch.

To cut small parts or shapes with sharp contours with a jigsaw, you need to choose small files. This requires using fabrics with a large number of patterns per inch. When using them, the jigsaw does not jam when making turns. The cut is created neat and thin. If large-sized plywood products are made, it is necessary to use blades with large teeth.

How to cut with a jigsaw

To obtain an accurate cut, a number of conditions must be met:

- The hand holding the jigsaw should only move vertically.

- All movements must be made as smoothly as possible, without jerking. In addition, they must be performed with maximum amplitude. This is necessary to use the entire canvas.

- With the second hand, the workpiece turns smoothly during operation.

- Do not put too much pressure on the workpiece with the saw. No lateral pressure on the blade is allowed.

- Artistic sawing is carried out only when the file moves from top to bottom. For this reason, the reverse movement must be performed without pressure.

When working with a hand jigsaw, it must not be guided along the marked line. The canvas should be drawn along the inside of the contour. This is due to the presence of a kerf after sawing. After completing the work, one of the clamps should be loosened. The frame of the device should not lose its elasticity.

Jewelry box

You can make a beautiful and spacious jewelry box for Valentine's Day or International Women's Day. To complete such a craft, you will need to use an accurate drawing. The work is divided into several stages.

Preparing the work area

Before you start cutting out the parts of the box, you should prepare your workspace. A special table is installed for this purpose. The craft will be created on it. In this case, the following rules are observed:

- There should be no unnecessary items at the table while working.

- The cutting device should always be at hand. A specific place is reserved for it.

- Crafting table. It is placed in a ventilated area. The room should be light and spacious.

However, it is not always possible to install a table for cutting with a jigsaw in the right place. TO ordinary apartment The workbench is usually placed on the balcony if it is insulated. At the same time, you can work on crafts in any weather.

Plywood selection

For the box you need to use a plywood sheet. When choosing a workpiece, you should pay attention to defects that often appear - cracks or knots. The workpiece is selected with a thickness indicated in the diagram. To transfer the drawing to the material, you should:

- Sand the workpiece with sandpaper. You should start with coarse-grained material. This treatment ends with fine-grain sandpaper.

- The surface must be level. To do this, you need to fix the sandpaper in the sanding device. If you don't have one, you can take a small block and wrap it in sandpaper.

- Grinding is carried out along the layers of wood.

- The workpiece is ground until its surface becomes as smooth as possible.

After such preparation, you should transfer the craft template onto it.

Transferring the template to a plywood sheet

Before starting sawing, you should transfer the prepared drawing to a plywood blank. First you will have to print the drawing on paper. To transfer, you must have tracing paper and a pen. First, the template is attached to the workpiece with tape. Having a blank in front of you, you should think about how to cut out the different elements of the box, saving the available material as much as possible.

Sawing out the box

When cutting, you need to adhere to some rules:

- The jigsaw should be positioned perpendicular to the product.

- It is necessary to ensure that all movements are performed as smoothly as possible. You should not rush while cutting - this way you can make a mistake and ruin a piece of material.

- It is necessary to use a sawing table.

- First you need to cut out internal elements. Only after this they begin cutting the contour.

When leaving the cutting line, it is necessary to correct the line with a needle file while assembling the product.

Advice! During work, your hands will get tired. In this case, productivity drops significantly. Fingers and eyes get seriously tired. All this can lead to hand injuries. This is why it is necessary to take breaks from work.

Assembling the box

Before assembly, you must familiarize yourself with the product drawing. Matching the pieces of a jewelry box does not require any delicate work. Before gluing different elements you need to make sure that they can be put together without problems. After several assemblies of the product without any difficulties, you should begin gluing the parts. Typically, a PVA composition is used for this purpose. During operation, it is necessary to eliminate any glue leaks.

Assembling a steam locomotive model

When the material is prepared and the drawing is printed, you should begin the process of transferring the diagram to the workpiece. In this case, it is necessary to take into account some operating rules. Many home craftsmen tend to transfer a drawing onto plywood using only a copy and a pencil. However, you can also use the “Black Ribbon”. When choosing this tool, the drawing is glued to the workpiece. Then the diagram is washed off the plywood with water, leaving only the marking lines.

Then you can make holes in the parts of the future locomotive. The parts of the locomotive contain parts of grooves cut out from the inside. To make such elements, holes should be made in them with a hand drill or an awl. The holes must be at least 1 mm in diameter. To avoid damaging the table surface when creating holes, you should place a board under the workpiece.

Now you can cut out the parts. You should not rush when cutting. The basic rule is to hold the jigsaw at right angles to the workpiece. All elements must be performed smoothly, avoiding unevenness.

All photos from the article

If you have good woodworking skills, then you should definitely download drawings of children's toys made of plywood online: with your own hands and using simple tools you can make the most different designs. At the same time, the toys will be environmentally friendly, durable, and most importantly, they will carry a piece of your parental love.

Tools and materials

So, if you decide to make toys, doll furniture or other crafts from plywood for kindergarten, then you should start with the selection of tools.

We will need:

- or a jigsaw for rough processing;

- jigsaw (manual or electric) for finishing cutting;

- drill with a set of drills of different diameters;

- sandpaper;

- wood files (several pieces of different shapes).

In addition, a workbench with a special stand for cutting would not be amiss: its presence, of course, is not mandatory, but working with it is much more convenient.

Note! Brushes and other tools may also be needed for finishing, but we will mention them in the appropriate section.

- plywood - best of all, birch, smooth and durable, without large defects, chips and separation of veneer layers (i.e. sheets of the first - second grade). Do-it-yourself children's toys from plywood are usually made using fairly thick blanks, so we purchase parts from 5 to 10 mm;

Advice! Laminated (melamine) plywood should only be purchased if you plan to make children's furniture. The price of this material is higher than that of standard glued sheets, and its strength and moisture resistance will be excessive in most cases.

- – PVA is well suited because it is non-toxic and has good adhesion. Can be used polyurethane adhesives with good fixation;

- exterior varnish– glossy, matte or semi-matte composition on water based. It is best to choose products with minimal toxin content, since sooner or later the toy will end up in the child’s mouth;

- decoration materials– paints, stickers, etc. Here the choice directly depends on your imagination.

Preparing for work

What can be done

So, we have the materials and tools, now let's think about what kind of structure we will cut and assemble? In principle, the possibilities of plywood are practically unlimited, but a novice master should focus on simple shapes, for which you can find many diagrams and manufacturing tips on our portal.

A brief overview is given in the table below:

| Category | Peculiarities |

| Metrics | Baby birth certificates made of plywood are souvenirs dedicated to the birth of a child. Typically, the metric includes the following details:

|

| Toys for little ones | The simplest drawings for cutting out plywood with a jigsaw for children allow you to literally make several simple toys for your baby in just a few hours: sorters, pyramids, mobiles over the crib, etc. All these products are characterized by a small number of parts, their simple shape and fairly large size. In this case, the mobile or pendant above the crib is usually made of thin plywood, while for sorters and pyramids it is better to take sheets from 10 mm. |

| Transport models | All kinds of cars, planes, tanks, etc. represent the lion's share of all products made from this material. Today, detailed drawings of plywood toys for children are widely available, so a product of any complexity can be made. |

| Doll furniture | Miniature pieces of furniture designed to be played with dolls or placed in Dollhouse, it is not at all necessary to buy in specialized stores. If you have, for example, drawings of a children's kitchen on hand, you can make a real masterpiece out of plywood with your own hands, which cannot be compared with any factory crafts. |

| Puzzles | For older children and teenagers, it is worth making several puzzles. As a rule, in addition to plywood parts of various shapes, they include metal rods, laces and various latches that allow the structure to be assembled and disassembled in different ways. |

Note! Their future owners can also be involved in the production of toys (subject to compliance with safety regulations). Of course, children's works made from plywood are not distinguished by the perfection of their forms, but a child will be much more willing to play with a car or an airplane made independently.

Constructing and transferring a drawing

When we have decided what exactly we will do, we move on to preparation: