The fire shield is designed to accommodate primary fire extinguishing means, power tools and fire equipment in production and warehouses, not equipped with fire-fighting water supply and automatic fire extinguishing installations, as well as on the territory of enterprises that do not have external fire-fighting water supply or when removing buildings (structures), external technological installations at a distance of more than 100m from external fire water sources.

Types and configuration of fire shields.

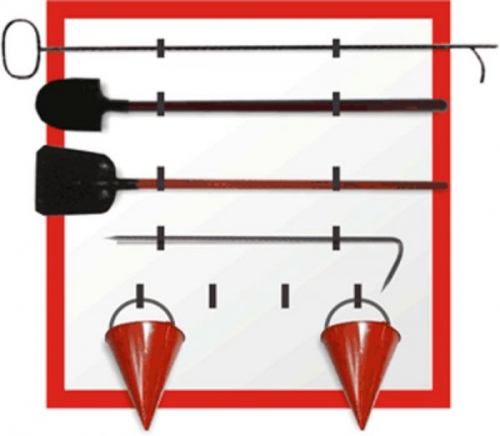

Fire shield ShchP-A class A

Equipment:

- Hook

- Shovel

- Bayonet shovel

- Two cone buckets

- Two powder fire extinguishers

Fire shield ShchP-V class B

Equipment:

- Fire cloth

- Shovel

- Bayonet shovel

- Conical bucket

- Three powder fire extinguishers

Fire shield ShchP-E class E

Equipment:

- Hook with wooden handle

- Shovel

- Dielectric scissors

- Dielectric gloves

- Dielectric boots

- One powder fire extinguisher

- Two carbon dioxide fire extinguisher

Fire shield ShchPP

Mobile fire shield equipment:

- Hook

- Bayonet shovel

- Fire cloth

- Conical bucket

- Two powder fire extinguishers

- Fire hose with barrel

Standards for equipping buildings (structures) and territories with fire shields.

| p/p | Name of the functional purpose of the premises and category of premises or external technological installations for explosion and fire protection and fire danger | Maximum protected area with one fire shield, sq. m. | Fire class | Shield type |

| 1 | A, B and C (flammable gases and liquids) | 200 | A, B, (E) | |

| 2 | B (solid flammable substances and materials) | 400 | A, E | |

| 3 | G and D | 1800 | A, B, E | |

| 4 | Premises for various purposes when carrying out welding or other flammable work | - | A | ShchPP |

Sand boxSand boxes should have a volume of 0.5; 1.0 or 3.0 cubic meters and equipped with a shovel. The design of the box should make it easy to remove sand and prevent the ingress of precipitation. Boxes with sand, as a rule, should be installed with shields indoors or on open areas where a spill of flammable combustible liquids is possible. |

|

Water barrelWater storage barrels installed next to the fire shield must have a volume of at least 0.2 cubic meters. and complete with buckets. Barrels must be protected from precipitation. |

|

Fireproof fabricFire-resistant fabric is designed to extinguish fires of substances and materials in an area of no more than 50% of the area of the fabric used, the combustion of which cannot occur without air access. In places where flammable liquids and gases are used and stored, the dimensions of the sheets can be increased to 2x1.5 m or 2x2 m. The canvas should be stored in a waterproof, lockable case, allowing for quick use of this product in the event of a fire. |

|

Compliance with measures fire safety is one of the priority requirements in the construction and operation of buildings. This is not surprising, since it depends on human life and property integrity. Fire safety is ensured different ways, starting from the installation of sensors and ending with the presence of fire extinguishers in the room. One of the constant elements of fire extinguishing is the fire shield. It can be seen in many public places and businesses. Such a shield is most often purchased ready-made and complete, but there is nothing difficult in making a fire shield with your own hands. The main thing is to comply with all the requirements of fire safety rules and GOST, as well as understand the types of fire shields.

Requirements for fire shields

Like any other items in our lives, on which human health and safety depends, fire shields are subject to GOST standards and rules. Knowing the requirements for fire shields, you can easily make the shield itself and at the next test you can be confident that it will pass successfully. Below we present only the basic requirements for fire shields. You can familiarize yourself with them in more detail in the Fire Safety Rules and GOST 12.4.026.

The fire shield is used to place manual fire extinguishing equipment, fire extinguishers and primary fire extinguishing equipment on it. It must be installed in all warehouses and production areas, not having automatic installation fire extinguishing or internal fire water supply. Also, such shields are installed on the territory of enterprises without an equipped external fire water supply or buildings located more than 100 m from external fire water sources. Shields should be placed in plain sight in easily accessible places.

The appearance of the shield should be white with a red border of 30 - 100 mm. This color makes it easy to spot the shield in dark time days. The dimensions of the fire shield are selected based on the convenience of placing all fire extinguishing equipment on it. Usually the size of the shield does not exceed 1500 cm in width and height. Hooks are attached to the boards for placing equipment, but it is prohibited to screw or nail the equipment. This is done in order to use fire-fighting equipment in the event of a fire without exerting effort to remove it.

Types of fire panels

There are several various designs and complete sets of fire shields. According to their own design features shields come in open and closed type. The shields themselves are made of wood or metal. It should be noted that the metal fire shield is most often produced in a closed type.

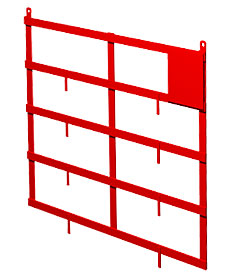

Open type fire shield

Shields of this type are extremely simple in design. They are a sheet of thin sheet metal or moisture-resistant plywood with hooks attached to it for placing equipment. Open fire shields can be mounted or attached. Wall-mounted ones are mounted directly on the wall, and attached ones are installed side by side on two racks.

Most often, fire shields open type can be seen in enclosed spaces and areas. Since open type panels provide open access to fire-fighting equipment, its safety is ensured in a closed room.

Closed fire shield

This type of shield is a metal box with doors made of chain-link mesh. Inside the shield there are hooks for placing fire-fighting equipment. Just like open shields, closed fire shields can be hinged or attached.

Unlike open shields, a closed type fire shield can be installed both indoors and outdoors. Access to the inventory is closed from outsiders with a simple lock or seal. This will make it easy to get everything you need in case of a fire.

Important! According to the rules, fire-fighting equipment must be protected from direct sun rays, as well as from various natural phenomena. Therefore, only a closed type fire shield is installed outside the premises. Open billboards on the street may not be accepted during inspection. But if the open shield is under a canopy, then this is permissible.

Regardless of what type, open or closed, fire shields have several categories according to explosion and fire hazard. And this primarily affects the configuration of the shield itself. Modern methods Fire fighting has become much better compared to the beginning of the last century. They are more advanced technically and allow you to cope with most fires without any problems. Depending on the degree of danger, there are five main categories of fire shields, and they all have their own markings:

- ShchP-A - the shield is intended for extinguishing class “A” fires (combustion of solid substances);

- ShchP-V - the shield is intended for extinguishing class “B” fires (combustion of liquid substances);

- ShchP-E - the shield is intended for extinguishing class “E” fires (burning electrical installations);

- ShchP-SKh - the shield is intended for agricultural enterprises and organizations;

- ShchPP - mobile fire shield.

Fire shield set ShchP-A

The set of shields type ShchP-A includes two foam fire extinguisher OVP-10 or OVP-5, crowbar, hook, two conical buckets, bayonet and shovel. As well as a barrel or other container for storing water with a volume of 0.2 m3.

Fire shield set ShchP-V

The set of shields of the ShchP-V type includes two fire extinguishers OVP-10 or OVP-5 and one powder fire extinguisher OP-10, a crowbar, a fire-fighting cloth, one conical bucket, a bayonet and shovel, as well as a box with sand. The volume of the box depends on the area of the fire extinguishing area.

Fire shield set ShchP-E

The set of shields type ShchP-E includes two carbon dioxide fire extinguishers OU-5 and one powder OP-10 or two powder OP-5 and two halon OX-2 fire extinguishers. Fireproof cloth, gaff or hook with wooden handle, shovel. Dielectric scissors, gloves, boots and a mat. And also a box of sand. As can be seen from the configuration, ShchP-E shields are designed to extinguish fires caused by short circuit, or there are electrical lines in the fire area.

Fire shield set ShchP-SKh

The set of shields type ShchP-SKh includes two air-foam fire extinguishers OVP-10 and one powder OP-10 or two powder OP-5. A crowbar, a hook, a shovel, two conical buckets, a bayonet and a shovel, a pitchfork and a fire-fighting cloth, as well as a barrel or other container for water with a volume of 0.2 m3.

Fire shield kit ShchPP

The set of shields type ShchP-SKh includes two air-foam fire extinguishers OVP-10 or two powder fire extinguishers OP-5. Scrap, bayonet shovel, a conical bucket, an asbestos fireproof sheet, as well as a protective screen and six racks for it. The main element of this type of shields is a trolley for transporting fire-fighting equipment, hand pump and a sleeve 5 m to it. A 0.2 m3 water container is required.

Important! There are two concepts - a fire shield and a fire stand. Essentially it's the same thing. But in fire regulations It is said that a stand is a shield that comes with a container of sand.

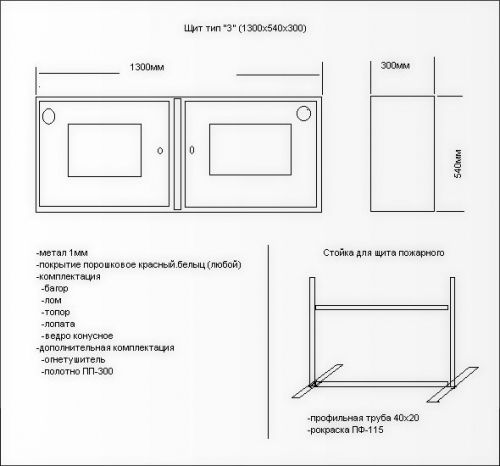

Despite the fact that today you can find ready-made fire shields on the market without any problems, many craftsmen prefer to make them with their own hands. Moreover, there are no particular difficulties in this. To do this, you will need very little - a simple drawing of a fire shield, tools and materials. Of course, in addition to materials, you will also have to spend money on fire-fighting equipment. Moreover, the lion's share of the cost of a fire shield is the price of fire extinguishers, shovels, scrap and other things, and the price of a finished fire shield will depend on this.

We begin work by creating a drawing. For open type shields you will need to draw a rectangular sheet indicating the dimensions. Usually the height of the shield is 1250 cm and the width is 1400. But if necessary, you can set your own dimensions. Then we indicate the places for attaching the hooks for the equipment.

Unlike an open type shield, the drawing of closed type fire shields will be somewhat more complicated. You will need to draw a top view of the shield and the assembly, as well as make a drawing of its doors. For open and closed type attachment panels, it is necessary to make a drawing of the racks.

How to make an outdoor fire shield

For this type of shield you will need a sheet of plywood or thin sheet metal, hooks for equipment and hanging on the wall, wooden blocks for frame 10x40, paint white and red. The dimensions and quantity of materials are selected based on the drawing.

First we create the frame. To do this, we lay out three parallel bars on the floor at an equal distance from each other. Then we lay 4 bars on top of them at an equal distance from each other at right angles to the three main ones and fasten them to the bottom ones. We carefully monitor the geometry of the frame. Distortions are not allowed. We lay the first and last bars along the edges, and distribute the rest between them. For safety wooden frame it can be painted with red paint and after drying, proceed to further work.

Now fasten the hinges on the back side of the frame for hanging on the wall. The loops themselves are attached to three main bars. It is advisable to use loops with an extended base. This will allow them to withstand the weight of the shield and securely fix them to the frame.

The next step would be fastening a sheet of plywood or metal A. To do this, we lay it on top of the already finished frame and secure it to the horizontal planks with 4 - 6 self-tapping screws. Immediately after this we place and secure the hooks for the fire-fighting tools. For reliability, we place the hooks themselves on horizontal slats. All that remains is to paint the shield according to the rules, wait for it to dry, and hang it on the wall.

Important! The number of horizontal strips depends on the number of tools placed on the shield.

If you plan to make the shield attached, then it is advantageous to make the frame from a metal profiled pipe. In this case, the outermost vertical strips will act as the legs of the shield. To create such a frame you will need a grinder and welding machine. The frame design itself will remain unchanged.

How to make an indoor fire shield

Unlike an open fire shield, creating a closed shield with your own hands is somewhat more difficult, but possible. For this purpose, thin sheet metal, chain-link mesh, red and white paints will be used.

We start creating such a shield with a frame. For this, a metal profiled pipe is used. Cutting pieces with a grinder required length, lay them out on the ground and weld them together. The frame should look like this. Along the edges there are two vertical racks. The horizontal parts of the frame are laid between them. After everything is laid out and adjusted, we take a welding machine and weld the parts of the frame together. We make sure that there are no distortions.

Now let's move on to creating the shield box. To do this, we use metal sheets and a regular metal corner 20x20. You can buy them in a certain size or cut them yourself using a grinder, after which we make a box. Since the metal is thin sheet, traditional arc welding will be somewhat problematic. But there is a way out. Firstly, you can use a resistance welding machine. Secondly, blind rivets can be used for connections.

We weld the cut corners together to form a box frame. Then we insert sheets of metal inside and drill holes for rivets. Then we insert the rivets inside and pull out their core. The result is a reliable weldless connection. Then we lay the box on the frame and weld the corners of the box to the frame. Finally, we install hooks for equipment inside the box.

Now it is necessary make doors. To do this, you can use strips of metal 5 - 10 cm wide. You just need to take metal 2 - 3 mm thick. Folding them into a frame, we weld them together. Next, take a piece of the Chainlink mesh and carefully weld it to the frame. All that remains is to install the hinges and make lugs on the doors for the lock.

Finally, we paint the closed-type fire shield and leave it to dry, after which we hang it on the wall. It is necessary to note the following: the frame of the attached closed shield is made by analogy with the open one.

There is nothing difficult about creating fire shields with your own hands. It's pretty simple design, and if available the necessary tool All work will take one or two days. At the same time, it is important to comply with all the requirements of fire safety rules and GOST.

Being prepared to fight fire is an important indicator of the safety of a home or other building. All tools and equipment for extinguishing a fire should be collected in one place, easily accessible and ready for use. This place is usually a fire shield.

Making a fire shield with your own hands is quite simple, although you can purchase a finished product. The main thing is that it fully corresponds to its purpose.

Requirements for fire shields

A fire shield is a place in which equipment intended for extinguishing a fire manually is collected. There are certain requirements for it state standards and fire safety rules.

The dimensions of the fire shield are not directly regulated; they must be sufficient to accommodate the equipment. The standards, in turn, determine the color of the shield. The main color is white, with a red stripe as a frame. With such ratios, the shield is clearly visible in poor lighting. It is necessary to have hooks on which tools and accessories will be placed.

Types and configurations

There are open and closed fire shields

An open shield is a rectangle made of plywood or metal sheet with a frame of beams and hooks, of a certain color and size. It can be mounted, hanging on the wall, or attached, placed on special devices.

The photo shows an open type fire shield

A closed fire shield is a metal box, the doors of which are covered with a metal mesh. It can also hang on the wall or stand next to it.

Placing such a shield is also possible inside buildings. Typically, a closed shield is sealed or locked.

The photo shows a closed type fire shield

Fire shields are also divided into categories that are determined by fire and explosion hazards. This division determines the configuration of the fire shield and its markings.

Thus, the fire shield ShchP-A, designed to resist combustion solids, must contain a 200-liter water barrel, two specially shaped buckets, a hook, a crowbar, two shovels and two foam fire extinguishers.

The ShchP-V shield, designed to counteract the combustion of liquid substances, among other things, contains a box with sand, a special cloth and a powder fire extinguisher. There are also special equipment for boxes of other categories.

Making a fire shield

To make a shield with your own hands, you will need material (plywood or sheet metal, hooks, bars, paints, etc.), tools (for cutting metal or wood, hammer, etc.) and appropriate equipment. Getting started consists of preparing a drawing, taking into account all regulatory requirements. Typically the side dimensions are 1400x1250 mm, but this is not a requirement.

If an open-type metal fire shield is being made, it is enough to cut a sheet of appropriate size, paint it and attach hooks for placing equipment. In the rear part, a frame made of beams is attached to the sheet. In addition, it is necessary to apply appropriate inscriptions and designations.

To make closed fire shields, you will have to make a drawing in three projections, as well as a drawing of the door. Attached fire shields also require a drawing of the racks.

The production of a closed shield begins by welding a tubular frame onto which a box made of a metal sheet and a corner measuring 20x20 mm is attached.

Similar news: