Often a finished house requires finishing cladding. Or the outdated walls of the building need to be updated by insulating them and covering them with other building materials. At the same time, 90% of developers in all cases want to save budget and choose inexpensive facade materials. That is why in this article we will look at how it is cheaper to sheathe the outside of a house and still get a beautiful decorative effect.

Important: when choosing a facade material for cladding a house, it is worth taking into account the difference in the linear expansion of the wall material and the material chosen for cladding. If this aspect is not taken into account, then under the influence of temperature changes the walls of the house and the cladding will expand each in their own way. As a result, cracks may form outside or inside the cottage.

Before you inexpensively decorate the walls of a cottage, you should take into account some points:

- So, when choosing a cladding material for a house, it is worth considering not only the cost of the cladding itself, but also the price of all the components needed to complete the work. In addition, if the cladding is carried out by craftsmen to order, then the price for the work should be added here.

- It is better to carry out house cladding in dry and warm seasons. This way the material will grip as tightly as possible, and its structure itself will not be damaged by moisture.

- It is advisable to insulate the house under the cladding in order to reduce the sound transmission of the material and increase the energy efficiency of the finished cottage. Mineral wool, penoplex or polystyrene are used as insulation.

- It is advisable to purchase all building materials from a trusted supplier who can provide quality certificates for all purchased goods. In this way, it will be possible to avoid possible defects and subsequent downtime.

Important: when choosing, how to cover the outside of a house cheaply and beautifully, give preference to non-flammable materials.

Facade plaster

The most budget option for making the exterior of your home attractive. In addition to the fact that facade plaster plays the role of a decorative finish, since it is most often textured, such a building mixture also has a number of other advantages, such as:

- The thermal insulation function allows you to additionally protect the walls of the house from the effects of cold;

- The soundproofing characteristics of facade plasters have also proven themselves to be positive;

- In addition, plaster mixtures have a positive effect on the safety of wall materials, protecting blocks or bricks from destruction, burning, swelling, etc.

For exterior use, the world of building materials offers the following types of plaster:

- Silicone. The most expensive type of textured plasters. But at the same time, with minimal costs for purchasing the mixture (in comparison with other finishing materials), it is possible to obtain strong walls of the house. The effect is achieved due to silicone resins added to the construction plaster mixture. In addition, thanks to this additive, silicone plaster does not allow water to pass through or absorb, and does not lose its color when exposed to ultraviolet radiation.

- Mineral. This type of building mixture is made on the basis of cement and sand. This mixture is resistant to fading, temperature changes, and mechanical stress. However, mineral plaster is more often used in industrial construction.

- Acrylic plaster. It contains acrylic, which allows you to obtain a protective film on the surface of the facade that has dried after plastering. Thus, the lined house is not afraid of dirt, moisture, dust and debris. In addition, the acrylic building mixture does not fade in the sun. The only disadvantage of such cladding is its weak vapor permeability.

- Decorative. It differs from the others in its finished shade. That is, in the store you can choose the final shade of the mixture and plaster the house in a single tone, in accordance with the intended design.

Important: for aerated concrete walls, you should purchase plaster specially designed for such blocks. It allows you to level out visible unevenness and defects and protect the walls from moisture and temperature changes.

Facade paint

Another budget option, designed to decorate the walls of an old house. Let's say we have an old brick house that has lost its luster. But the walls are still quite strong. In this case, paint can be used as a facade “new thing”. This material is a building mixture that includes a structuring filler. The thickness of this paint is 10 mm, which allows you to form a protective and at the same time decorative barrier on the walls of the cottage.

The peculiarity of this façade paint is that it can be applied even to an unprepared surface without first sealing cracks and chips. Thanks to its structure, facade paint will hide all unevenness. In addition, the coloring mixture is able to “breathe”, which has a beneficial effect on both stone/block walls and wooden ones.

Siding

This cladding material occupies one of the leading positions in the construction market. And competitiveness is determined not only by the reasonable price of the material, but also by technical characteristics. Siding is thin long panels 150x500 mm, which have a perforated edge in their design for simplified installation of the material to the frame. The second edge of the panels has a slight protrusion that allows you to cover the attachment points of the underlying elements. Thus, the cladding takes on integrity and attractiveness.

Siding is also popular because it comes in a wide range of colors. Or rather, it is made in various designs - wood, marble, stone, brick, etc. Thus, you can give the house any look in accordance with the intended design.

There are several types of siding based on the type of material from which it is made:

- PVC siding. These are cellular panels that are lightweight. Thanks to this hollow structure, siding panels act not only as decorative cladding, but also additionally insulate the walls of the house. This material does not rot, is not afraid of water, and is resistant to burning and rotting.

- Metal siding. Thin panels made of steel, zinc or aluminum. They have a thickness of 5 mm. Easy to install, resistant to the negative effects of precipitation and corrosion. You can sheathe with such material yourself, without resorting to the help of professionals.

- Wood siding. A natural material that is characterized by increased environmental friendliness, attractiveness and low thermal conductivity. However, wood panels cannot withstand moisture. And even if the panels are carefully treated with antiseptics and varnishes, wood has a shorter service life than metal or PVC.

- Fiber cement siding. The material is made from a mixture of cement and polymer fibers. The result is a material that is strong and resistant to various negative factors.

Important: siding can be installed on top of the ventilated façade system. The material does not interfere with air microcirculation.

Tree

To cover a house in a country style, you can use edged or unedged boards. The first option is lumber with perfectly smooth edges. The second type of board is lamellas, sawn from unprepared and uncleaned logs. As a result, bark, bast and sapwood remain at the ends of the boards. This type of cladding material is used for cladding walls with a herringbone or overlapping pattern. The panels overlap one another from bottom to top. With proper care, the cladding will last 15-20 years. Then the boards will need to be replaced. Although for a small country house this finishing option is ideal. After all, wood retains heat, provides walls with breath, and looks simply beautiful.

If you want to use wood as cladding, but in such a way that the house looks rich, then you can use a block house. These are the same wooden panels, but with a convex side. That is, it imitates a log. Cladding a house with a block house looks colorful and expensive at the low cost of the material.

Advice: if you want to save even more, you can buy siding for a block house.

Decorative tiles

Clinker tiles are often used for cladding a house. It can imitate brick, stone, etc. This material is made from a mixture of water, clay and glaze. The result is an environmentally friendly material of low weight. Therefore, tiling a house does not require strengthening the foundation. The tile interacts well with the sun, water, low and high temperatures. And such material is completely inert to fire. You can lay tiles yourself, following all the principles of laying. Thus, a budget finishing option will be available.

Panels for house cladding

You can cover the house with light PVC panels. This material is also inexpensive and attractive. The finishing can be done in the form of natural stone, marble, brick, wood, etc. The panels are light in weight and therefore easy to install. With the help of such facing slabs you can create a beautiful decorative finish for the entire cottage. Moreover, the panels can be combined by finishing the base and corners of the house as stone, and the walls as wood or simply decorated in a uniform shade.

Remember, a house finished with the right materials not only gets a new appearance, but also gets a longer service life.

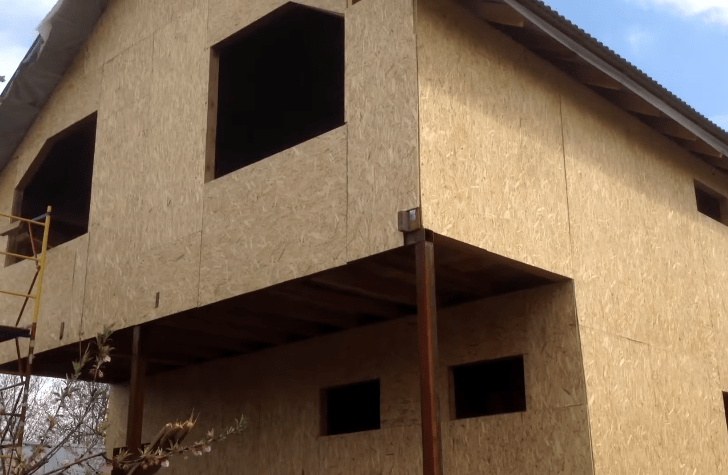

External wall cladding is one of the final stages of building a frame house. And here the choice of material is of great importance: the microclimate in the premises, the mechanical strength of the walls, and the reliability of protection from moisture and cold depend on it. In addition, the cladding serves as the basis for finishing materials, and in some cases acts as a finishing coating and is responsible for the aesthetic appearance of the building.

The cladding gives the building frame a certain rigidity and takes on part of the load. This means that one of the main criteria is the mechanical strength of the material in bending and compression, and the absence of shrinkage during operation. The walls must retain their original shape for years, regardless of environmental conditions. In addition, the cladding must be resistant to moisture, sudden temperature changes, and the effects of microorganisms.

Next, you need to pay attention to the ease of installation of the material and its flexibility during processing. If you plan to sheathe it yourself, this aspect is of great importance, because it determines how much effort and time the work will require. The material should be easy to cut and drill, but at the same time maintain density in cuts, not crumble, not crack. And, of course, it must be durable so that you don’t have to change the skin every 10-15 years.

Material selection

There are several types of materials that more or less meet these requirements: moisture-resistant plywood, fiberboard, OSB, edged boards, fiberboard. They have similar characteristics and are widely used in frame construction. To make a choice, it is worth familiarizing yourself with the main properties and features of each of them.

Oriented Strand Boards (OSB)

OSB panels are rightfully one of the most popular materials when arranging frame structures. They consist of layers of laminated wood chips and chips, with the fibers in the outer layers arranged longitudinally and transversely in the inside. Synthetic resins and wax are used to hold the chips together, giving the finished boards water-repellent properties.

Standard production involves the production of these slabs in several categories:

- OSB-1 is intended exclusively for interior decoration of dry rooms with reduced mechanical loads;

- OSB-2 is used when installing load-bearing structures in rooms with low humidity;

- OSB-3 is a moisture-resistant board of increased rigidity used for the installation of load-bearing structures indoors and outdoors.

In terms of the quality-functionality-price ratio, OSB-3 is the most optimal, and this material is widely used in private construction for wall cladding, the manufacture of load-bearing partitions, and reusable formwork when pouring concrete structures. The slabs lend themselves well to grinding, cutting, drilling, and hold nails tightly even at a distance of 6 mm from the edge. Such cladding can simultaneously serve as a decorative covering for walls; you just need to treat it with waterproof varnish or paint it.

Advantages of OSB:

- the dense structure prevents delamination and splitting of the material during processing and during operation;

- the plates have elasticity and high strength, excellent resistance to vibrations, compression loads, and various deformations;

- the material is resistant to weathering and temperature changes;

- OSB is resistant to microorganisms; insects and rodents do not like it.

Flaws:

- very low vapor permeability;

- flammability;

- content of toxic compounds (phenol and formaldehyde).

Main characteristics

Prices for OSB (oriented strand boards)

OSB (oriented strand board)

Cement particle boards (CSP)

This material is a compressed mass of M500 cement and wood shavings (usually softwood). A standard slab has three layers: the outer ones are made of small chips, the inner one is made of large ones. In addition to the main components, the composition contains hydration additives, the mass fraction of which does not exceed 3%. DSP is characterized by resistance to moisture, high strength, and long service life. The slabs are widely used in private and industrial construction, for indoor and outdoor work.

When covering a frame, such slabs serve as an excellent basis for cladding, decorative plaster, and painting, since they form a perfectly flat and smooth surface. The material can withstand 50 cycles of complete freezing and thawing without losing its characteristics; subsequently, the strength of the slabs decreases by about 10%. Among wood-based panel materials, DSP is a leader in terms of environmental and technical indicators.

Advantages:

- very low hygroscopicity;

- resistance to mold and other microorganisms;

- DSP are not damaged by insects and rodents;

- the material does not emit toxic substances;

- low thermal conductivity;

- Fire safety.

Flaws:

- mechanical processing of plates requires significant effort;

- DSP is heavy compared to other materials;

- When cutting and drilling slabs, a lot of fine dust is generated, so you need to work in a respirator;

- high price.

Specifications

Fiberboard (Fiberboard)

The material is sheets of compressed shavings, usually coniferous. During the pressing process, the raw materials are highly heated, which makes it possible to achieve maximum density without the use of adhesives. Thanks to this, fiberboard is an environmentally friendly material, and therefore suitable for both outdoor use and finishing of residential premises. The shavings contain natural resin, which acts as an antiseptic and protects the slabs from mold.

In terms of strength, fiberboard is noticeably inferior to natural lining and OSB, but it surpasses them in heat and sound insulation properties.

Windproof board "Beltermo"

Now on the construction market, fiberboards are represented by insulating boards of several well-known brands, the most popular of which are Beltermo and Izoplat. For cladding a frame house, slabs with a thickness of at least 25 mm are used; thinner sheets are used indoors.

Advantages:

- light weight;

- low thermal conductivity;

- ease of installation;

- the material does not delaminate or crumble;

- high vapor permeability;

- resistance to moisture and microorganisms;

- absence of harmful substances in the composition.

Flaws:

- high price;

- a long stay without decorative finishing causes slight deformation of the sheets;

- The outer lining of fiberboard requires spacer jibs in the frame or rigid inner lining.

Specifications

Prices for fibreboards (fibreboards)

Fiberboard (Fiberboard)

Gypsum fiber sheets (GVL)

GVL consists of pressed gypsum reinforced with cellulose fibers. Due to its high strength, the material is suitable for creating load-bearing surfaces, therefore it is widely used in frame construction. It differs from plasterboard in its greater density, uniformity, and absence of a cardboard shell. In terms of frost resistance, sound insulation properties, as well as resistance to moisture and combustion, gypsum fiber boards are also several times higher than gypsum boards.

GVL installation is carried out using frame and frameless methods. For external wall cladding, the first option is used, where the sheets are fastened to the load-bearing posts using self-tapping screws. The material is easy to cut and drill, and, despite its heavy weight, is quite convenient to install. This cladding serves as an excellent basis for finishing with tiles and decorative plaster.

Advantages:

- low hygroscopicity;

- vapor permeability;

- absence of toxic compounds;

- fire safety;

- high heat and sound insulation properties.

Flaws:

- lack of ductility and fragility when bending the sheet;

- heavy weight.

Specifications

Plywood

Plywood is made by gluing together thin sheets of veneer from various types of wood (most often coniferous and birch). The sheets are laid perpendicular to each other relative to the location of the fibers, which helps to increase the mechanical strength of the material and increases resistance to deformation. For the outer cladding of frame walls, plywood with increased moisture resistance is used, which is marked FSF. The thickness of the sheets should be from 9-10 mm; thinner material will not provide the required rigidity to the frame.

The grade of plywood is not particularly important for sheathing, and you can use the cheapest unsanded 4/4 grade boards.

From the outside, all defects will be hidden under the curtain wall, so there is no point in overpaying. If the cladding technology is followed, the plywood covering will serve for years without losing its qualities.

Advantages:

- high bending and compressive strength;

- moisture resistance;

- wear resistance;

- ease of processing and installation;

- frost resistance.

Flaws:

- flammability;

- content of formaldehyde resins;

- tendency to chipping.

Specifications

Plywood prices

Edged board

Using edged boards for sheathing is the most economical option. Wood is an environmentally friendly material, affordable, and easy to install. Boards can be filled not only horizontally, but also at an angle of 45-60 degrees. To save material, boards can be fastened in increments of up to 30 cm, although more often the sheathing is made continuous. This design perfectly strengthens the frame and is a ready-made base for a ventilated façade.

In order for the cladding to be reliable, boards should be chosen with a thickness of at least 25 mm; they can be tongue-and-groove for greater joint density. You cannot use raw lumber: during the drying process, the wood will begin to warp, and deformations of the finishing coating may appear.

Advantages:

- wood does not emit harmful substances and has excellent vapor permeability;

- boards are easy to process;

- the work does not require large financial costs.

Flaws:

- flammability of the material;

- wood is susceptible to damage by insects and microorganisms;

- Fitting and fastening elements takes a lot of time.

Prices for edged boards

Exterior cladding technology

Installation of slabs on a finished frame is carried out using the same technology, regardless of the type of material. Simultaneously with the sheathing, vapor barrier and wall insulation are carried out, and finishing can be done immediately upon completion of construction or after some time. Let's look at the installation technology using the example of covering a frame with OSB boards.

Sheathing can be done in two ways - with and without lathing. In the first case, the vapor barrier layer is located between the frame and the OSB, in the second - on top of the sheathing. The option with lathing is used in cases where OSB acts as the basis for plastering, painting or tiling; the second method is used, as a rule, when installing a ventilated facade. Otherwise there are no significant differences.

Step 1. Start covering from the very corner. The first sheet of OSB is applied to the frame posts so that the bottom edge completely covers the bottom frame of the house. Be sure to check the horizontal level. It is also recommended to install the slab itself horizontally rather than vertically - this provides the structure with greater rigidity. To fasten the material, galvanized self-tapping screws with a length of at least 50 mm are used. It is necessary to retreat about 10 mm from the edge of the OSB, the fastening step along the perimeter of the sheet is 15 cm, in the center - 30 cm.

Advice. To firmly fix the slabs, the length of the hardware must exceed the thickness of the OSB by at least 2.5 times. If the self-tapping screw enters the frame beam less than 30 mm, under the influence of loads the sheathing will begin to tear away from the supporting base.

Step 2. The next plate is installed next to the first, leaving a gap of 2-3 mm for thermal expansion. In the same way, set the horizontal level and screw the casing to the frame guides. The joints of the plates must be in the middle of the rack, only in this case the fastening will be as reliable as possible. Fix the remaining slabs in a circle, leaving open areas for doorways.

Step 3. The second row of sheathing must be installed with ligation of vertical seams. The same gap of 2-3 mm is maintained between the lower and upper plates. When sheathing openings, you should use whole sheets, not scraps - the fewer joints, the more airtight the sheathing. Cutouts in the sheets are made with a jigsaw or a circular saw, having previously made markings accurate to the millimeter. The edges of the cuts after installing the slab should perfectly coincide with the lines of the openings.

Step 4. The top plates are installed so as to completely cover the top trim. If the house has two floors, the interfloor piping should be closed in the middle of the slab - under no circumstances should OSB be joined on this line.

Gallery 1. An example of the construction of a one-story frame house finished with OSB boards

Gallery 2. Sheathing a two-story frame house with OSB boards. Example

Step 5. After completing the installation, a windproof membrane is attached over the casing. Its sheets are stretched horizontally and fixed with staplers to the OSB. At the joints, the film is overlapped and taped. The material should not be pulled too tight, but there should be no sagging.

Step 6. Next, the sheathing slats are stuffed for finishing in increments of 50-60 cm. The slats must first be treated with a protective compound and dried. After this, you can begin installing siding, lining or other decorative covering for the house.

On a note! If you plan to paint the facade from OSB, then the membrane, accordingly, is installed only on the inside of the house.

With this method of cladding, the insulation is placed on the inside of the walls in the cells of the frame and covered with a vapor barrier film. Slabs for interior decoration, for example, plasterboard or the same OSB, are sewn on top of the vapor barrier.

Video - How to sheathe the outside of a frame house

Country houses and cottages are usually built from wood, concrete or brick, which have insufficient resistance to environmental influences. As a result, new houses very quickly become old and unattractive. Therefore, in order to protect the structure from precipitation, wind and other weather conditions, the building is usually additionally finished with other building materials. And the first question that arises is: what is cheaper to sheathe the outside of a house without saving on the quality of finishing?

Basic building materials for house cladding

Today there is a wide variety of different building materials that are applicable for cladding buildings. And every year something new appears. Each building material has its pros and cons, but generally they are of good quality and durability. Therefore, one of the main consumer characteristics is the price of the product, and the question of how cheap it is to sheathe the outside of a house is of paramount importance when choosing a material.

For the maximum cost per square meter, we will conventionally take 1000 rubles, which is quite affordable for most residents of our country. Of course, the definitions of “cheap and expensive” are different for everyone. But provided that the cost of facing the building with stone or brick costs at least 3,000 rubles. for 1 sq. m (cost of material plus labor costs), price 1000 rubles. seems acceptable enough.

clapboard, block house and other wood materials

Thanks to the fashion for naturalness and naturalness, houses made of lumber have become especially popular today. The excellent characteristics of such a structure are significantly spoiled by one serious drawback. Wood is subject to rapid destruction from environmental influences and requires mandatory protection. Therefore, it is not enough to build it, it is necessary to additionally protect it.

There is another side to the issue. Not every owner of a country plot can afford to build a new house or cottage to replace the old building. Therefore, it is necessary to bring the building that is already available into a decent form. And the question immediately arises of how to sheathe the outside of an old wooden house cheaply and extend the structure.

Strange as it may sound, it is better to protect a wooden house with lumber, that is, the same wood. Therefore, such materials as block house (wooden siding under a log), lining and others are perfect as cladding for such buildings. These lumber are treated during production with all the necessary means to prevent rotting and destruction of the wood.

At the same time, the cost of such materials is quite affordable; a Ukrainian or Russian-made block house can be purchased at a price of 350-700 rubles. per square meter, lining for external work - 400-1000 rubles. The cost of imported building materials, of course, is somewhat higher.

It is worth considering other options, the cheaper it is to sheathe the outside of a wooden house. As well as other buildings made of bricks, concrete blocks and other building materials.

Facade thermal panels

Depending on the material from which the building is built, as well as the requirements for heat and sound insulation, as a rule, they choose how to cover the outside of the house cheaply (the photo below demonstrates this option).

If a building made of wood retains heat well, then a house made of brick or concrete has very cold walls. Therefore, for its cladding it is preferable to choose materials with good thermal insulation. The best option in this case are thermal panels consisting of polyurethane and ceramics. Today, Russian manufacturers have established the production of thermal panels quite well, so the cost of this material is quite reasonable. If the cost of cladding from foreign companies varies between 1600-2500 rubles. for 1 sq. m, then domestically produced panels can be purchased for 900-1300 rubles per square.

Fiber cement panels

For stone buildings, another good option for cheap exterior sheathing is fiber cement panels. This is a relatively new material, the production of which has already been launched by Russian manufacturers, and they predict a great future for it. Excellent strength characteristics and ease of installation make this material especially attractive. The cost of imported material is 1600-2000 rubles. for 1 sq. m, while the domestic analogue can be purchased for 700-900 rubles, without losing quality.

Fiber cement panels are highly durable, reliable and resistant to changing weather conditions. The only drawback is their rather significant weight, so they are practically not used for finishing wooden or panel houses.

Vinyl or metal siding

We choose further, the cheaper it is to sheathe the outside of the house. It is also convenient and profitable to decorate a brick or concrete building with siding. In addition, due to its light weight, this building material can also be used for cladding wooden buildings.

Both types of siding have their advantages and disadvantages. withstands greater temperature differences, is more durable and reliable, but strongly removes heat from the walls of the building. Although vinyl material does not heat, it does not cool either.

At the same time, the cost of different types does not differ much: the price of metal siding is about 100-195 rubles, the vinyl type - 190-200 rubles. per linear meter. However, when covering a large building, this relatively minor difference can result in a significant amount.

Sheathing with corrugated sheets

Another option, the cheaper it is to sheathe the outside of a house, is corrugated sheeting. You probably can’t imagine a more inexpensive material. The price of this building material varies from 160 rubles. up to 350 rub. per linear meter depending on the region and brand of sheet. It should be taken into account that, as a rule, a profiled sheet with small stiffeners is selected. One of the disadvantages of this material is its poor thermal conductivity, which can be compensated for by additional thermal insulation. Just like siding, corrugated sheeting is attached to the frame, and the sheathing process is much faster due to the larger area of the attached sheet. Installation of corrugated sheeting does not require special knowledge and skills, so you can cover a house with this material yourself, even alone, saving on hiring professional builders.

Both siding and corrugated sheeting can be used for finishing houses made of timber or logs, as well as panel houses.

Today, these are probably the most common materials that can be purchased at a reasonable price. But thanks to the rapid development of industry, who knows what the building materials market will offer us tomorrow?

When developing a project for a private building, you must immediately decide what to cover the outside of the house with. After all, it is the correct finishing of the facade that will make the house not only presentable, but also warm, so you need to carefully select materials for its insulation and decorative design. Without good finishing, the house will look ugly and untidy, and will not be protected from destructive external influences, such as moisture, active solar radiation, wind, thermal changes, etc..

The modern construction market offers a very large assortment of insulating and decorative materials, from which you can choose the ones that suit every taste and financial capabilities.

Requirements for façade cladding materials

To prevent dampness from appearing in the house, to be comfortable and warm, and to make the house look aesthetically pleasing from the outside, cladding materials must meet certain requirements.

Based on them, you should choose the right option. So, the cladding must have the following qualities:

- have low thermal conductivity to retain heat inside the house;

- have vapor permeability - condensation should not form inside the insulation layers;

- be moisture resistant - do not absorb or retain moisture inside the material;

- have absolute or increased heat resistance - the sheathing must withstand high temperatures and not deform or ignite under their influence;

- be inert to chemical influences - do not change its characteristics when similar substances come into contact with it;

- be protected from the influence of microorganisms, not serve as a breeding ground for insects and rodents;

- do not decompose and do not lose physical properties when exposed to ultraviolet rays.

In order for the cladding to be effective in all matters, it is necessary not only to reliably attach decorative material to the walls, but, following technology, to cover them with a whole system of layers, each of which will play its role.

There are two main systems for insulating a house, and the choice will depend on what material is planned to be used for decorative finishing and on the insulation used. In one of their systems, the insulation is attached directly to the wall using glue, in the other - along the created sheathing.

Plastering a house with plaster

When using insulating boards that have a sufficiently high density, for example, polystyrene foam, fiber cement or tightly compressed glass wool in mats, which will later be covered with plaster on top, wall sheathing is not necessary.

Most often, this principle is applicable on smooth brick or reinforced concrete walls. In this case, the plating is done as follows:

- on the wall of the house, at the height at which Insulation will be installed, a metal holder profile will be fixed, selected according to the thickness of the selected insulation boards. The profile is leveled to a perfectly flat horizontal level;

- the walls are cleaned of dust and, before applying glue, moistened with water for better adhesion;

- further on insulation boards pre-diluted special glue is applied;

- the first row of slabs is installed on a metal profile and pressed firmly against the wall;

- the next row is installed on the first according to the brickwork system - in a dressing;

- having secured two or three rows of slabs with glue, each of them is additionally secured with dowel fungi;

- further work continues according to the same system to the very top. Then the insulation is installed on other walls in the same way;

- When the layer of glue under the insulation has dried, it is necessary to glue all corners of the building, window and door slopes with corners with reinforcing mesh. They are fixed with the same glue, its excess is removed with a spatula;

- after the corners have dried, the reinforcing serpyanka mesh must be secured to the entire insulated surface;

- The surface on which the serpyanka sheet will be glued is coated with a thin layer of glue. A reinforcing mesh is fixed on top of it, smoothed with a spatula, and excess glue is also removed;

- when the surface dries well, it needs to be covered with polymer plaster, a layer of 2-3 mm;

- The final stage will be the application of decorative plaster, selected in the appropriate design style of the building.

Plaster prices

Plasters

Sheathing a house using sheathing

An insulating facade system using lathing can be installed in one or two layers. The position of the frame bars will depend on how you plan to install the decorative cladding.

- To install the sheathing correctly, it is better to first mark the wall. In this case, you need to take into account the width of the insulation mats.

- Then bars or metal profiles are mounted on the surface of the walls.

- If you are sheathing a wooden wall, then before laying insulation, you should attach a vapor barrier film to the entire surface of the walls.

- Next, insulation mats are laid between the sheathing bars. If necessary, they are secured to the wall with mushroom anchors.

- Having installed the insulating layer, they stretch it on top superdiffusion membrane, securing it to the sheathing bars with construction staples stapler.

- Next, you can install decorative cladding material.

Another option for installing the sheathing is done a little differently.

- Markings are also made on the wall and hangers are fixed along it at a distance of 40-60 cm from each other. Their edge holders should protrude from the wall to the thickness of the insulation and wooden blocks that will be attached to them.

- These elements will be fastening not only for the bars, but also for the installed insulation.

- Insulation mats are marked and cut in those places where they will be placed on metal elements.

- Then the insulation is mounted on the wall, and a diffuse membrane is stretched and secured on top of it.

- Next, wooden sheathing bars are installed in the hangers, they press the insulation tightly against the wall and secure them in metal holders with self-tapping screws.

- Decorative sheathing material is also installed on top of this system, using the installed sheathing bars as guides.

Types of decorative cladding

Modern materials make it possible to create an imitation of brickwork on a wooden wall, or vice versa - to transform a brick house into a wooden frame. For this, claddings such as siding made from different materials, wooden lining, block house, thermal panels, ceramic or stone tiles and others are used. It is necessary to find out in advance how each of the skins is attached and what it looks like in the end - this will largely determine which insulation system to choose for it.

Clinker thermal panels

Clinker thermal panels are one of the modern materials for insulation and decoration of facades.

They have appeared on the construction market relatively recently, and have already gained wide popularity. This is not at all surprising, since they have many positive qualities.

- One of the main advantages is that this material performs two functions at once: insulation and decorative cladding.

- The panels perfectly imitate brickwork and are produced in a variety of colors, so they can be matched to any style and taste.

- They give the surface absolute neatness and aesthetics.

- This type of cladding is convenient and relatively easy to install on the wall.

- Thermal panels can be used to cover any surface - wood or brick.

- The light weight of the panels makes it possible to do without additional strengthening of the foundation of the old building.

- Since the materials have a low percentage of water absorption, the façade can be washed from sludge with water under high pressure.

- The tightness of the panels on the wall does not allow cold air to penetrate to the wall of the house.

Thermal panels have a polyurethane foam or polystyrene foam base onto which clinker tiles are pressed. The warm substrate increases the thermal insulation qualities of the panels by two to four times, and creates an optimal vapor permeable microclimate for the walls, which allows you to preserve the material from which the house is built for a longer period.

The structure of the panels is a layer of insulation and decorative tiles “like brick”

The structure of the panels is a layer of insulation and decorative tiles “like brick” - Clinker tiles protect the insulation base from external factors such as wind, precipitation, and direct solar ultraviolet rays.

- Clinker panels are very securely attached to the wall and can last 45-60 years without repair work, without losing their original appearance.

- The panels are assembled into a single plane using existing locking joints (tongues and grooves), which ensures tight adhesion.

- Straight, wall thermal panels and corner elements for them are produced, which facilitate the task of decorating the corners of the building, making them absolutely neat, not different from the general appearance of the walls.

- Thermal panels are reinforced with plastic guides that prevent deformation and mechanical stress of the facing material.

Installation of thermal panels

- Before you begin installing the panels on the wall, it is necessary to inspect it for various bulges, significant depressions and chips, which can greatly impede quick installation. Therefore, it is necessary to bring the surface of the walls to a perfectly smooth state.

- When installing panels on surfaces that have large irregularities, for example, the walls of a log house, they are covered with a lathing made of wooden beams.

- In this case, it is very important to correctly calculate the location of the sheathing elements so that the fastening of the panels is successful. Each of the panels to be fixed must have at least three sheathing bars to create the necessary rigidity of the sheathing.

The diagram clearly shows the places of fastening to the wall or sheathing and the dimensions of the panel itself and the protruding locking ridges.

- After the wall surface is completely covered, the seams between the individual tiles are filled with a special grout. This completely isolates the insulation from external influences and gives the wall design the look of natural brickwork.

Video: facing a house with clinker thermal panels

Prices for thermal panels

Thermal panels

Covering a house with siding

Another fairly popular way to transform a facade is. It is produced in various forms, imitating wooden and stone wall coverings.

It is produced from different materials using two technological processes - monoextrusion or coextrusion. The first of them is the molding of siding panels from a homogeneous mass, and second - manufacturing two-layer elements. The top layer of material is protective from external influences, and the bottom is the basis of the panel.

Truly high-quality siding has a whole range of advantages:

- it is resistant to mechanical stress, such as shocks and scratches, while at the same time having good elasticity;

- The material is fire-safe and resistant to thermal extremes. The high performance qualities of the material allow it to be used in various climatic conditions;

- siding is not susceptible to the formation of colonies of microorganisms or damage by insects;

- high-quality material is not seriously affected by ultraviolet rays, so it does not lose its original appearance for many years. The service life of siding is about ten years;

- the panels provide reliable protection for the building walls from wind and precipitation;

- the material does not require special care and can be easily tidied up with a stream of water under high pressure. The surface itself does not absorb dirt;

- SP siding is special to give any facade an aesthetic appearance. Numerous shades and the possibility of combining them open up great possibilities for design solutions;

- the material is non-toxic and therefore harmless to human health;

- In addition, compared to other materials, siding is quite easy to install and affordable.

Types of facade siding

Saydi ng For cladding facades, they are made from vinyl, aluminum, thin steel, cement-cellulose mass and based on wood raw materials.

- Aluminum and steel siding is mainly used in industrial facilities, but is also used for finishing private homes. The material is produced in a variety of colors, so it will perfectly decorate any facade of the house.

- The facing material from wood fibers and their connecting components is made by pressing raw materials under high pressure and then coated with protective paints. This siding is also well suited for cladding the facades of private houses.

Fiber cement siding - great for covering plinths

Fiber cement siding - great for covering plinths - A cement-cellulose version of the cladding material is most often used for cladding the basement sections of a building.

The most common is vinyl siding

The most common is vinyl siding - The most popular and affordable is vinyl siding. It is widely used for finishing private buildings, and it justifies itself with a long-term operational period and other positive qualities. Since this material is purchased and used more often than others, it is worth considering in more detail.

Vinyl siding

This type of siding is produced in the form of stacked panels-strips that have a perforated edge through which they are attached using nails or self-tapping screws. In addition, the strips have a latch lock for connecting adjacent panels to each other.

The material is available in the form of one, two or three “boards”, which simplifies and speeds up the installation of siding on the wall.

The pattern of the siding can also be different. Often this is the usual “lining”, but other types are rapidly gaining popularity, for example, “ship plank” or “herringbone”. The surface of the material can imitate the texture and color scheme of different materials. The panels can be attached in a horizontal or vertical position, but for everything to go well, you need to foresee the location of the sheathing bars in advance.

At the production stage, vinyl siding is often coated with paint containing titanium dioxide, which keeps the surface in its original condition for many years and gives any color a pastel softness. At the same time, you need to know that bright shades of the material indicate the absence of this component, so such coatings lose their original color much faster.

Prices for the siding range

Installation of siding panels

Installation work for installing siding horizontally begins from the bottom of the house. Adjacent panels are overlapped and secured with a lock. The panel is secured to the sheathing with nails along the top, through special holes.

When installing, you should strive to minimize the number of vertical joints. If the dimensions of the wall do not allow this (longer than the standard dimensions of the panels), use a special joining profile, installing it strictly vertically from the bottom to the top of the wall.

During the installation of siding on the walls, additional decorative elements are installed, which will give the facade completeness - external and internal corners, soffits, ebbs, window and door slopes, etc.

Video: installation of facade siding

Block house

The block house is made of natural wood and is a board with a semicircular surface. A house sheathed with this material imitates a log house.

On the flat side of the block house board there are two longitudinal grooves, which are designed to relieve stress from the load and improve ventilation. In addition, for convenient installation, there is a groove on the lower edge of the panel, and a tenon on the upper edge.

Block house panels are available in several standard sizes - from 3 to 6 m in length, from 20 to 45 mm thick and from 99 to 220 mm wide.

For the manufacture of this cladding material, mainly coniferous species are used, such as pine, spruce, larch. With proper processing and quality raw materials, this wood will serve for many years as facade cladding. Wood is naturally endowed with excellent qualities, which man has skillfully used to build and decorate homes.

What are the main advantages of this facade material:

— ecological purity characteristic of natural wood;

- lightness and strength;

— resistance to high and low temperatures;

— ease of installation;

- the ability to “breathe” - this creates a special comfortable microclimate in the house;

- affordable price compared to solid logs.

The material is easily attached to the sheathing of the insulation system and is perfect for finishing not only facades, but also interior walls.

Block house prices

Block house

Installation of a block house

- The first thing that needs to be done is to adapt the wood to the conditions in which it will be attached to the facade. To do this, the panels of the block house are laid out on a prepared base, for example, spread polyethylene, and left for a day.

- Each panel should then be completely covered with the first layer of antiseptic.

- After it dries, as a rule, all the flaws of the material appear, such as roughness and unevenness. They must be removed using sandpaper.

- A second layer of antiseptic must be applied to the leveled surface. There are similar products on sale that already contain dyes - they will help protect the wood from exposure to ultraviolet rays. If such processing of the material is used, then it no longer requires further painting or varnishing.

- The block house is attached to the sheathing, starting from the bottom of the house wall. The first panel is laid with the tongue facing upward - this is done so that during precipitation, water does not get into the groove of the panel.

- In places where you have to screw the board right through, the self-tapping screw should be recessed and disguised. As a composition for covering such holes, you can use wood glue mixed with fine sawdust. You can close the hole with a dowel, the cut of which is leveled and tinted to match the color of the panel.

- Installation continues using the tongue-and-groove system along the entire plane of the wall. The material is secured with self-tapping screws to the sheathing.

- At the corners, the panels are joined through installed corner boards or through a cut at an angle of 45 degrees.

- If it is necessary to lengthen the panel, two of its segments are connected with a block of the same width as the boards themselves. It is secured on the reverse side, and then the joint is sealed with the mentioned mixture of glue and sawdust.

Video: cladding the facade with a block house

Country houses and cottages are usually built from wood, concrete or brick, which have insufficient resistance to environmental influences. As a result, new houses very quickly become old and unattractive. Therefore, in order to protect the structure from precipitation, wind and other weather conditions, the building is usually additionally finished with other building materials. And the first question that arises is: what is cheaper to sheathe the outside of a house without saving on the quality of finishing?

Today there is a wide variety of different building materials that are applicable for cladding buildings. And every year something new appears. Each building material has its pros and cons, but generally they are of good quality and durability. Therefore, one of the main consumer characteristics is the price of the product, and the question of how cheap it is to sheathe the outside of a house is of paramount importance when choosing a material.

For the maximum cost per square meter, we will conventionally take 1000 rubles, which is quite affordable for most residents of our country. Of course, the definitions of “cheap and expensive” are different for everyone. But provided that the cost of facing the building with stone or brick costs at least 3,000 rubles. for 1 sq. m (cost of material plus labor costs), price 1000 rubles. seems acceptable enough.

Decorating the house with clapboard, block house and other wood materials

Thanks to the fashion for naturalness and naturalness, houses made of lumber have become especially popular today. The excellent characteristics of such a structure are significantly spoiled by one serious drawback. Wood is subject to rapid destruction from environmental influences and requires mandatory protection. Therefore, it is not enough to build a wooden house; it must be additionally protected.

There is another side to the issue. Not every owner of a country plot can afford to build a new house or cottage to replace the old building. Therefore, it is necessary to bring the building that is already available into a decent form. And the question immediately arises: how to sheathe the outside of an old wooden house cheaply and extend the life of the building.

Strange as it may sound, it is better to protect a wooden house with lumber, that is, the same wood. Therefore, such materials as block house (wooden siding under a log), lining and others are perfect as cladding for such buildings. These lumber are treated during production with all the necessary means to prevent rotting and destruction of the wood.

At the same time, the cost of such materials is quite affordable; a Ukrainian or Russian-made block house can be purchased at a price of 350-700 rubles. per square meter, lining for external work - 400-1000 rubles. The cost of imported building materials, of course, is somewhat higher.

It is worth considering other options, the cheaper it is to sheathe the outside of a wooden house. As well as other buildings made of bricks, concrete blocks and other building materials.

Facade thermal panels

Depending on the material from which the building is built, as well as the requirements for heat and sound insulation, as a rule, they choose how to cover the outside of the house cheaply (the photo below demonstrates this option).

If a building made of wood retains heat well, then a house made of brick or concrete has very cold walls. Therefore, for its cladding it is preferable to choose materials with good thermal insulation. The best option in this case are thermal panels consisting of polyurethane and ceramics. Today, Russian manufacturers have established the production of thermal panels quite well, so the cost of this material is quite reasonable. If the cost of cladding from foreign companies varies between 1600–2500 rubles. for 1 sq. m, then domestically produced panels can be purchased for 900-1300 rubles per square.

Fiber cement panels

For stone buildings, another good option for cheaply covering the outside of a brick house is fiber cement panels. This is a relatively new material, the production of which has already been launched by Russian manufacturers, and they predict a great future for it. Excellent strength characteristics and ease of installation make this material especially attractive. The cost of imported material is 1600-2000 rubles. for 1 sq. m, while the domestic analogue can be purchased for 700-900 rubles, without losing quality.

Fiber cement panels are highly durable, reliable and resistant to changing weather conditions. The only drawback is their rather significant weight, so they are practically not used for finishing wooden or panel houses.

Vinyl or metal siding

We choose further, the cheaper it is to sheathe the outside of the house. It is also convenient and profitable to decorate a brick or concrete building with siding. In addition, due to its light weight, this building material can also be used for cladding wooden buildings.

Both types of siding have their advantages and disadvantages. Metal siding can withstand greater temperature differences, is more durable and reliable, but strongly removes heat from the walls of the building. Although vinyl material does not heat, it does not cool either.

At the same time, the cost of different types does not differ much: the price of metal siding is about 100-195 rubles, the vinyl type is 190-200 rubles. per linear meter. However, when covering a large building, this relatively minor difference can result in a significant amount.

Sheathing with corrugated sheets

Another option, the cheaper it is to sheathe the outside of a house, is corrugated sheeting. You probably can’t imagine a more inexpensive material. The price of this building material varies from 160 rubles. up to 350 rub. per linear meter depending on the region and brand of sheet. It should be taken into account that, as a rule, a profiled sheet with small stiffeners is selected. One of the disadvantages of this material is its poor thermal conductivity, which can be compensated for by additional thermal insulation. Just like siding, corrugated sheeting is attached to the frame, and the sheathing process is much faster due to the larger area of the attached sheet. Installation of corrugated sheeting does not require special knowledge and skills, so you can cover a house with this material yourself, even alone, saving on hiring professional builders.

Both siding and corrugated sheeting can be used for finishing houses made of timber or logs, as well as panel houses.

Today, these are probably the most common materials that can be purchased at a reasonable price. But thanks to the rapid development of industry, who knows what the building materials market will offer us tomorrow?

Despite the development of construction technologies and the introduction of innovative materials, wood does not lose its position as a material for the construction of low-rise buildings. Statistics say that the share of new wooden buildings in private housing construction is about 23%, second in percentage only to brick low-rise buildings and houses made of concrete blocks of various modifications. With such popularity of residential buildings made of wood, there is a demand for cladding a wooden house on the outside, which can give a new building the archaic appearance of a Russian hut and, conversely, turn old buildings into a modern “teremok”.

Why do you need cladding of wooden walls, requirements for finishing materials

The centuries-old practice of using wooden residential buildings in Russia shows their fairly acceptable performance qualities. In modern conditions, finishing the outside of a house with wooden walls has several goals:

- Protection of walls from unfavorable climatic factors - precipitation, wind, icing, sudden temperature changes. The outer layers of the cladding material should not be saturated with sedimentary moisture and condensation.

- Creation of reliable thermal insulation and waterproofing of residential premises. The lower the material’s thermal conductivity and vapor permeability, the better.

- Protection of walls from mechanical damage such as cracks and chips.

- Additional soundproofing of the interior of the house.

- Protection of the wooden part of the house from dampness, rot, fungi.

- Decorating the facade of a building in a certain architectural and artistic style. To ensure that the appearance of the building remains unchanged for as long as possible, it is advisable to select a material that is resistant to direct sunlight and ultraviolet radiation. This reduces the chance of fading/discoloration of the trim.

- Protecting the house from open fire, ensuring the fire safety of the building.

The surface can be protected and reinforced in various directions

An important requirement for cladding is ease of installation when covering walls, which minimizes the need to use special equipment

As a result, the optimal solution for covering the outside of a wooden house would be to use facing materials adapted to perform utilitarian (protective) and aesthetic functions. Not all of them have these properties equally, so sometimes you have to choose between beauty and reliability.

How does finishing affect the heat and sound insulation of a house?

Even if cladding materials protect the outer walls of a wooden house from moisture, sun and mechanical damage, this does not guarantee a significant increase in the thermal and sound insulation of the building. The energy efficiency of the cladding will be higher if a layer of insulation (mineral wool, penoplex, polystyrene) is placed under the cladding, which is placed in the voids that are left between the wall and the cladding during installation. In some cases, the insulation is already present on the installed components - most often this is done in sandwich panels.

Two in one - beauty and insulation in one bottleThe most popular materials for external cladding

When choosing what to cover the outside of a wooden house cheaply, but with maximum thermal protection and a beautiful decorative effect, there are always several options. The most popular materials for external cladding are those based on stone, wood and plastic. Let's consider the advantages and disadvantages of using these materials when cladding the outside of the house.

Cladding with clapboard and block house

Lining (or carriage board) is a thin cladding board made of natural wood. From an environmental point of view, lining is an ideal material for covering a house with wooden walls, since the house is made entirely of natural wood.

Additional Information. The term “lining” has firmly taken root in everyday speech to refer to cladding boards having a tongue-and-groove joint, produced by industry in accordance with GOST 8242-88. The original purpose of carriage boards was the covering of carriages, which then “migrated” to the construction industry.

Advantages of lining

The main advantages of external wall cladding with clapboard are:

the relatively light weight of the facing coating, which allows saving on strengthening the foundation;

The lining is essentially a thin board

- natural lining wood does not contain toxic substances and has a beneficial effect on the human body;

- the wall of the house “breathes” and does not accumulate condensation, thereby preventing the formation of mold and mildew;

- excellent heat-protective and noise-absorbing properties;

- clapboard cladding is endowed with high performance qualities and is resistant to temperature changes, high humidity and mechanical damage.

- the outer surface of the carriage board is easily painted, allowing you to give the facade of the house color shades of any design style;

- good ventilation of clapboard walls thanks to special air ducts in the solid boards.

Disadvantages of lining and how to deal with them

Among the disadvantages of wooden cladding, the following factors should be noted:

- flammability characteristic of natural wood;

- excess moisture contained in the damp skin;

- the presence of natural structural defects;

- susceptible to destruction from insects.

To increase the period of trouble-free operation of the carriage board, it is treated with special compounds applied to the outer surface of the board:

antiseptics - to protect wood from rotting, bacteria and insects, and from exposure to ultraviolet radiation;

impregnations - to impart fire-fighting properties;

stains and varnishes - to create color shades and protect against moisture, sunlight and pests.

Installation of the lining is carried out only after preliminary processing. What type of lining to choose for external cladding

Cladding boards are divided into four quality classes, depending on the type and location of defects and the presence of knots:

the “Extra” class is assigned to a board with a smooth surface, free of any defects, knots and cracks;

class A - the board has individual knots and there are no potholes or holes from fallen knots;

class B - the board has cracks, knots or holes from them, depressions and dents, which were repaired directly at the factory with putty;

class C is a complete analogue of defects like class B boards, but not eliminated.

Such a detailed classification of carriage boards allows the developer to determine for himself the budget cladding option that matches the chosen facade design while minimizing costs and ensuring the required quality. An elite “teremok” is unthinkable without “extra” class lining, while for an unbiased dacha residential extension, class B and C boards are sufficient.

Where and when is a block house used?

A modern version of flat paneling is a block house (from the English block house) with a convex front surface, imitating a segment of a rounded log, and a flat rear surface. A wall covered with a block house looks colorful, not inferior in attractiveness to traditional Russian huts.

You can see the use of a block house in home decoration in the video:

Being, at its core, an improved lining, the block house is endowed with the same pros and cons characteristic of the lining board.

Cladding with brick, decorative stone and tiles

Using brick, decorative stone or tiles for cladding will make it possible to clad the outside of a house cheaply and in the shortest possible time. Even an old, nondescript wooden building, clad in brick or an artificial imitation of natural stone, cannot be distinguished from brick mansions or stone castles.

Transforming a wooden house into a brick one has two main goals:

If the house looks unpresentable, was built from wood of dubious quality, with violations of the architectural geometry of the building, then brickwork can correct the facade and hide the flaws.

Brickwork is necessary not so much to improve the facade, but to increase the strength and rigidity of the wall structure. The renovated house becomes heat-protected and will be able to serve its owners for a long time.

With proper cladding, a gap is left between the brick and the wood. Pros and cons of using brick for finishing

Using brick for the external cladding of a wooden house has significant advantages over the use of other materials:

availability of material;

low water absorption, providing excellent resistance to sedimentary moisture;

resistance to cyclical and sudden temperature changes;

good noise-absorbing and heat-insulating properties;

long service life exceeding 20 years.

Brick cladding is a good budget option in terms of price/quality compared to the costs of cladding with decorative coatings.

Among the disadvantages, it should be noted the large weight of the facing masonry, which creates additional load on the foundation. It is advisable to calculate before starting work whether it is worth strengthening it.

Additional nuances of finishing a house with brick in the video:

Porcelain tiles and clinker

Among artificial stones, porcelain stoneware has become widely popular, the cladding of which gives a truly “stone” solidity to the entire residential complex. The purchase and installation of porcelain stoneware slabs is more expensive than other cladding methods, but many years of operation that do not require repairs and the always fashionable architectural style more than pay for all costs.

Along with porcelain tiles, other modifications of facing tiles are produced that imitate brick and natural stones (like granite, basalt or marble), which can give an individual flavor to a simple wooden building.

Clinker tiles produced by extrusion followed by firing at a temperature of 1250 °C have particularly high strength and wear resistance. Clinker tiles are characterized by minimal water absorption, since technological firing gives the tile an almost glassy structure with water-repellent properties.

Siding

In the Russian building materials market, siding refers to cladding panels that have a perforated edge on one side for fastening to the frame, and on the other, an edge with a slight protrusion for covering the fastenings of underlying elements.

Stone-look siding panels

This gives the cladding integrity and an attractive appearance.

Additional Information! The term “siding” often refers only to wall cladding panels of certain sizes. This approach is very incorrect, since siding translated from English means “outer cladding.” This is how in the 19th century in the USA and Canada they called planed painted wooden boards nailed to the wall so that the bottom edge of the board slightly overhangs the top edge of the board installed lower. With this “inlet,” sedimentary moisture rolled straight down the cladding without penetrating the wall. In general, even clapboard or block house can be called siding, since they also refer to external cladding.

Types of siding

Siding panels are made by pressing, followed by applying the texture of wood, stone and other materials. There are several types of siding panels:

- Wood siding. Obtained by pressing wood pulp at high temperatures. It has increased environmental friendliness, attractiveness, and low thermal conductivity. Disadvantage: poor resistance to moisture.

- PVC siding. This material is also called vinyl siding. It is represented by lightweight PVC panels with a cellular structure, used as an independent heat-insulating layer due to its fairly low thermal conductivity.

About the nuances and procedure for finishing a house with siding in the video:

Vinyl siding is the most popular budget facing material, which compares favorably with other types of siding in the following indicators:

- does not increase the weight load on the foundation;

- has no tendency to corrosion and rotting;

- tolerates temperature changes from -50. up to +60 °C;

- maintains an attractive, fresh appearance for over 20 years;

- easy to care for, easy to clean.

Metal siding. Aluminum, zinc or steel are used for its production. The thickness of the plates is 5 mm, installation is much simpler than other types of cladding.

Fiber cement panels. Siding made from a mixture of polymer fibers and cement. It is durable and has a high degree of fire safety.

Facade paint

Painting walls is one of the most inexpensive ways to increase their curb appeal. Also, well-chosen paint provides additional protection for wooden walls from ultraviolet radiation and moisture. Based on this, the requirements for paint and varnish coatings were formed:

Weather resistance. In addition to weathering, this includes sun rays, sudden changes in air temperature and other negative influences.

The manufacturer labels its products in accordance with its purpose

Biosecurity. Properly selected and applied paint will not be eaten by any insect, and in addition, it prevents the formation of mold, fungi and the development of the rotting process.

Safety. After drying, the paint layer should not release toxic substances.

Durability. The paint must retain all its properties throughout its entire service life - usually 5-7 years.

Types of paints

In order not to get confused by other characteristics, it is enough to understand for what purposes one or another base is better suited.

Oily. An old-timer on the market, inferior to newcomers in quality, but superior in price. Of the minuses: it takes a long time to dry, fades quickly, smells unpleasant. Requires dilution with drying oil to work.

Acrylic. They dry quickly and are well absorbed into the surface, do not react to ultraviolet radiation, are vapor permeable and environmentally friendly.

Alkyd. Based on the result of staining, they are divided into matte and glossy. Thanks to the resins contained in the composition, the painted surface becomes moisture resistant. No strong odor.

Silicone. In addition to all other advantages, silicone paint additionally increases the mechanical strength of the painted surface.

The type of paint is also indicated on the packaging. Nuances of using paint and varnish coatings

Savings and good painting results depend on the correct use of paints and varnishes.

In addition to the cost, you also need to look at the paint consumption ml/m²

When choosing paint from a foreign manufacturer, you need to understand that there are no serious frosts in Spain, unlike Finland. Therefore, for hot regions it is better to take Spanish paint, and for frosty regions - Finnish products.

It is equally bad for painting when it is done in damp or hot weather. In the first case, the adhesion of the paint to the surface deteriorates, and in the second, it may crack due to drying too quickly. If painting occurs in the morning, then first of all you need to check whether dew has fallen. The ideal option is a dry, slightly cloudy day, with air humidity up to 50% and temperature +5/+20 °C.

Painting is a very simple process, but before you start, do not forget to study the instructions on the paint can, if only because it indicates how many layers should be applied for a good result.

How to install the external cladding of a wooden house

Regardless of the type of material used for cladding wooden walls, measures for cladding the outer wall come down to a unified algorithm.

Installation of all types of cladding is carried out approximately the same

Treatment of the outer surface of wooden walls with antiseptic compounds. The purpose of the treatment is to prevent possible destruction of wood from various biological factors. After installing the facing panels, the walls will no longer be accessible for processing.

Arrangement of a vapor-proof layer for natural air circulation in the wood of the wall using films, foil or special vapor barriers.

Construction of a frame (sheathing) for a heat-insulating layer.

Installation of thermal insulation. Foam plastic, penoplex or mineral wool are used for placement between the panels and the wall

Arrangement of waterproofing.

Installation of facing materials.

Prices for finishing materials for cladding wooden houses

To choose a budget option for cladding the external walls of a wooden house, you need to be guided by at least the average prices on the line of cladding materials. The following price ranges are indicated on the websites of organizations offering cladding materials:

lining - from 150-250 rub/m² for coniferous wood to 300-700 rub/m² for valuable wood species;

block house - from 200 to 600 rubles/m²;

artificial stone - from 600 to 3000 rubles/m²;

Specialized stores always have a wide selection of quality and prices.

- brick - within 800-1600 rub/m²;

- wood siding – from 60 to 200 rubles/m²;

- PVC siding – from 100 to 300 rubles/m²;

- metal siding – from 200 to 700 rubles/m²;

- fiber cement siding - from 1000 to 3000 rubles/m².

In addition to price, it is worth assessing the availability of material acquisition and delivery. If the material is difficult to find, then if the quantity is calculated incorrectly, there is a risk of subsequently purchasing the missing cladding at exorbitant prices or completing part of the work with another cladding.

It is important! When choosing an inexpensive cladding material, you need to pay attention not only to the prices for the cladding, but also to the prices of components, as well as consumables.

In this case, finishing a wooden house will be inexpensive for the developer and will allow you to build a new house or reconstruct an old one with minimal costs.

About a non-standard solution in the exterior decoration of a house in the video:

Conclusion

The choice of a budget cladding option should not be reduced to a simple arithmetic operation showing where the least amount of money will be spent on purchasing the material.

It is also necessary to take into account the cost of installation work, during which it becomes necessary to equip the frame and sheathing for thermal insulation, as well as the resource for trouble-free operation of the house. For example, the cost of wood siding is not high, but wood cladding must be periodically impregnated with special compounds to maintain its antiseptic properties. Practice has shown that the most budget-friendly option is PVC siding and middle-quality lining.

Also, on our website you can get acquainted with the most popular projects wooden houses with various options for facade finishing, from construction companies presented at the exhibition of Low-Rise Country houses.

Some building materials from which walls are erected immediately imply the need for exterior finishing of the house: the resulting picture is very unsightly. Others may lose their appeal over time. And the third case is extensive crack formation, which is “treated”, but the results remain visible. In all these cases, the question arises: “How to sheathe the outside of the house.” Moreover, most often it is necessary to “sheath” it - without using mortar or other similar means that require a lot of money and time. I want to do everything quickly and, very preferably, inexpensively, and, if possible, with my own hands. Oddly enough, there is a choice of materials and technologies, and a considerable one.

Basic Rules

When selecting materials for cladding a house from the street, be sure to remember that in order to maintain normal humidity in the rooms, the vapor permeability of the materials must decrease from inside the room to the outside. That is, the exterior finishing should conduct steam better than the wall material. Then the increased humidity, which is typical for our homes, will be removed through the walls naturally (explanations in the photo).

When deciding what is best to sheathe the outside of the house, do not forget to take into account the vapor permeability of the materials

If this principle is violated, moisture will accumulate at the interface of materials with different vapor permeability. It condenses, creating conditions for rotting and the development of fungi and mold. In winter it freezes, destroying the wall material and/or finishing. Sooner or later such a system will have to be dismantled and rebuilt.

The trouble is that only wood meets this requirement. Most other materials for exterior decoration of a house have low vapor permeability. The problem is solved in two ways:

- A ventilated facade is being installed. A ventilated gap with a width of 60 mm to 150 mm is left between the wall or insulation layer (with high vapor permeability) and the finishing. Ventilation holes are left at the bottom of the cladding at the rate of 75 cm2 for every 20 m2 of wall, including windows and doors. Air will enter through them. There are exit holes at the top. With this device, moisture will be removed from the wall material or insulation, and the outer cladding will protect from precipitation and perform a decorative function.

The principle of finishing a house using a ventilated facade

- The finishing material is attached directly to the wall. But from the inside the wall must be protected by a layer of vapor barrier. In this case, the penetration of vapors into the wall material is prevented and it remains dry. Excess moisture is removed by the ventilation system.

Today the second option is becoming increasingly popular. Very effective thermal insulation materials have appeared that can significantly reduce heating costs. But they have very low vapor permeability (expanded polystyrene and extruded polystyrene foam). When using them, only the second humidity control scheme is possible. When choosing what to cover your house with, consider these points.

Wood paneling