2. Composition and content of PPR - work projects and technological maps.

2.1. By Decree of the State Construction Committee of Russia dated April 19, 2004 No. 70, from January 1, 2005, instead of SNiP 3.01.01-85* “Organization of construction production”, SNiP 12-01-2004 “Organization of construction” was introduced. 2.1.1. At the same time, by Letter of the Ministry of Justice of the Russian Federation dated April 7, 2005 No. 01/2599-VYA, Resolution of the State Construction Committee of the Russian Federation dated April 19, 2004 No. 70, which approved SNiP 12-01-2004, was denied state registration.

2.1.2. Thus, from a formal point of view, SNiP 3.01.01-85* remains valid.

2.2. SNiP 12-01-2004 “Construction Organization” is advisory in nature and establishes for voluntary application general rules for conducting construction, procedures for monitoring the quality of construction and assessing the compliance of completed real estate projects (buildings and structures) with the requirements of project documentation and the terms of contracts.

2.3. As such, SNiP 12-01-2004 “Organization of construction” provides only for the presence of a project for organizing construction, but does not mention the existence of a project for the production of work, in contrast to SNiP 3.01.01-85 * “Organization of construction production”, which established (or before This establishes) the mandatory composition and content of work projects.

2.4. The return of the work project as a mandatory document as part of the organizational and technological documentation was carried out by Order of the Ministry of Regional Development of Russia dated December 27, 2010 No. 781, when the set of rules was approved and put into effect on May 20, 2011 - SP 48.13330.2011, which updated SNiP 01/12/2004 “Construction Organization”. This set of rules (see clause 5.7.4) provides for the development of the PPR in full and in part. The work project must be developed in full:

- during any construction in urban areas;

- during any construction on the territory of an existing enterprise;

- during construction in difficult natural and geological conditions, as well as technically particularly complex objects - at the request of the authority issuing a construction permit or for construction, installation and special work.

In other cases, the PPR is developed by decision of the person carrying out construction in an incomplete volume.

2.4.1. The full scope of work project includes:

- calendar plan for the production of work on the facility;

- construction master plan;

- schedule for the arrival of building structures, products, materials and equipment at the site;

- schedule of movement of workers around the facility;

- schedule of movement of the main construction vehicles around the site;

- technological maps for performing types of work;

- layout of geodetic signs; an explanatory note containing decisions on geodetic work, decisions on laying temporary networks of water, heat, energy supply and lighting of the construction site and workplaces;

- justifications and measures for the use of mobile forms of work organization, work and rest schedules; solutions for work execution, including winter time;

- need for energy resources; the need and connection of construction camps and mobile (inventory) buildings; measures to ensure the safety of materials, products, structures and equipment at the construction site;

- environmental protection measures; occupational health and safety measures in construction; technical and economic indicators.

2.4.2. The part-time work project includes:

- construction master plan;

- technological maps for performing certain types of work (as agreed with the customer);

- layout of geodetic signs; an explanatory note containing the main decisions and environmental measures; measures for labor protection and safety in construction.

2.5. In addition to the development of SNiP 12-01-2004 “Construction Organization” before its actualization, several methodological recommendations were developed and are still in effect, clarifying the content and procedure for developing work projects and technological maps:

- MDS 12-29.2006 “Methodological recommendations for the development and execution of technological maps”;

- MDS 12-81.2007 “Methodological recommendations for the development and execution of a construction organization project and a work execution project.”

2.5.1. MDS 12-29.2006 is a degraded copy of the “Guidelines for the development and approval of technological maps in construction for SNiP 3.01.01-85 * “Organization of construction production””.

2.5.2. MDS 12-81.2007 is actually a modified, towards simplification, copy of appendices 2-5 to SNiP 3.01.01-85 * “Organization of construction production”.

2.6. According to clause 6.2. MDS 12-81.2007 “Methodological recommendations for the development and execution of a construction organization project and a work execution project” work execution projects are developed for the construction of the facility as a whole and (or) its component parts, for the work of the preparatory period of construction, as well as for the implementation of certain types of construction installation work. As part of the project for the construction of the facility as a whole and (or) its components, the following are developed:

- calendar plan for the production of work on the facility;

- construction master plan;

- schedule for the arrival of building structures, products and materials at the site;

- schedule of labor requirements;

- schedule of the need for basic construction machines;

- technological maps for certain types of work;

- maps (diagrams) for quality control of work;

- occupational health and safety measures;

- explanatory note.

2.7. The mandatory presence of a work project, its composition and content, depending on the type of work performed, is also provided for and regulated by other current regulatory documents.

2.7.1. Work on the construction of load-bearing and enclosing structures of buildings and structures, in accordance with clause 1.4. SNiP 3.03.01-87 “Load-bearing and enclosing structures” should be carried out according to an approved work plan (WPP), which, along with the general requirements of SNiP 3.01.01-85, must provide for:

- sequence of installation of structures;

- measures to ensure the required installation accuracy;

- spatial immutability of structures during their enlarged assembly and installation in the design position;

- stability of structures and parts of a building (structure) during construction; degree of enlargement of structures and safe working conditions.

2.7.1.1. The combined installation of structures and equipment should be carried out according to the work plan, which contains the procedure for combining work, interconnected diagrams of installation tiers and zones, and lifting schedules for structures and equipment.

2.7.1.2. If necessary, as part of the PPR, additional technical requirements must be developed aimed at increasing the manufacturability of the structures being erected, which must be agreed upon in the prescribed manner with the organization that developed the project and included in the as-built working drawings.

A work production project is often developed for particularly difficult installation, finishing or special work. The PPR for installation of prefabricated structures includes:

Calendar (shift, hourly) schedule for the production of work on the facility, combined with schedules for the need for workers and machinery;

Construction master plan for this type of work with the arrangement of the necessary cranes, routes for their movement, organization of storage facilities and permitted movement zones within the site;

Methods and schemes for the production of work and, if necessary, a technological map (maps) for the production of work indicating the mandatory and controlled geodetic work;

Technical and economic indicators for the work project;

An explanatory note with the necessary explanations and justifications for the decisions made in the PPR.

The development of a project for the installation of a building frame begins with the determination of the basic provisions (general concept of work), which include installation methods, the necessary installation equipment and the timing of the work.

These basic provisions for the work are agreed upon with the project customer (construction or installation organization). They should be based on the working drawings of the structures recommended in the project, so that the PPR takes into account their specific features and proposes a technology for their installation. Basic provisions are developed for all proposed options for carrying out installation work. Options for work production methods should differ not only in the installation mechanisms used, but also in the technology of installation work. The choice of the optimal option is carried out by comparing technical and economic indicators: the features and cost of mechanization options, the complexity and duration of work for each of them.

The main provisions must contain an explanatory note with the scope of work, a fragment of the construction plan for each option, diagrams and an enlarged work schedule and technical and economic indicators. The development of a work project begins only after approval of one of the installation options proposed by the contractor, the head of the installation organization and the general contractor (the construction organization carrying out the construction).

The work project establishes the sequence of installation of structures, measures to ensure the required accuracy of installation of elements, spatial immutability of structures during the process of enlargement and installation, stability of parts of the building during the construction process, the degree of enlargement of structures and, necessarily, the safety of the work. The completed PPR is reviewed, approved and accepted for execution by the installation organization.

The main part of the PPR for a complex construction process or simple construction work is a technological map, which includes the following sections:

1. Scope of application - composition and purpose of the construction process;

2. Material and technical resources and selection of basic mechanisms - data on the need for materials, semi-finished products and structures for the designed scope of work, the need for mechanisms, tools, inventory;

3. Calculation of labor costs and machine time - a list of operations performed, the volumes of labor required to perform them;

4. Hourly or shift work schedule - the relationship of processes over time, the sequence and total duration of their implementation;

5. Technology and organization of a complex process - list and technological sequence of operations, composition of units or teams of workers. The section should contain working drawings of mounting devices and rigging; slinging diagrams for the main structural elements of the frame; locations of installation scaffolds, fences, passages and stairs;

6. Quality requirements. Operational control. Acceptance of work - instruments and equipment used for control, instructions for its implementation, mandatory measures for operational quality control of installation work performed and connections of installation elements, assessment of the quality of individual processes;

7. Safety precautions - measures to ensure the safety of construction processes, including organizing the safe operation of installation mechanisms;

8. Technical and economic indicators - labor costs per unit of measurement, duration of work according to the technological map.

System of regulatory documents in construction

Departmental building codes

INSTRUCTIONS

for the development of projects for the construction of oil and gas product pipelines

1. Developed by an oil and gas engineering company - the All-Russian Research Institute for the Construction and Operation of Pipelines and Fuel and Energy Complex Facilities (JSC VNIIST) and the closed joint-stock research and design implementation company NGS-Orgproektekonomika.

2. Agreed:

Gosgortekhnadzor of Russia, letter N 10-03/814 dated 12/16/99;

Gosstroy of Russia, letter N 9-17/517 dated December 28, 1999;

JSC AK Transneft N 23-01-15/173 dated 12/21/99.

3. The instructions were developed on the instructions of the Department of Foreign and Intersectoral Programs and Coordination of Federal Target Projects in the Fuel and Energy Complex of the Ministry of Fuel and Energy of Russia.

4. Approved and put into effect by order of the Ministry of Fuel and Energy of Russia No. 37 dated 02/04/2000.

The developers express their gratitude to the specialists of Stroytransgaz JSC, Neftegazspetsstroy JSC, Neftegazspetsmontazhproekt JSC and Tsentrtruboprovodstroy JSC for useful comments and suggestions presented on the first edition of the Instructions.

1 area of use

1.1. This Instruction applies to the construction, reconstruction and expansion of the linear part of main and field pipelines intended for the transportation of natural gas, oil and petroleum products.

1.2. The instruction establishes requirements for the composition, content, procedure for the development, execution, coordination and approval of work projects (WPP).

1.3. The instructions should be used by all organizations, regardless of their form of ownership and business, carrying out organizational and technological design and construction of main and field pipelines.

1.4. This Instruction has been developed to develop and ensure the mandatory requirements of SNiP 3.01.01-85* "Organization of construction production".

1.5. The requirements of the Instructions may apply to the construction of underwater pipelines (sea, river and offshore).

2. General provisions

2.1. In accordance with SNiP 3.01.01-85 * it is prohibited to carry out construction and installation work without an approved work plan. Deviations from the decisions of the work execution plan (WPP) are not allowed without written approval from the organizations that developed and approved it.

2.2. For technically complex structures, pipeline elements or types of work (underwater crossing, air crossing, road crossings, etc.), separate technological maps are developed as part of the PPR. When constructing long-distance pipelines with a long construction period, an additional PPR is developed for the work of the preparatory period.

2.3. The PPR for the construction of the facility is developed by the contracting construction organization. For individual structures and types of work (a set of works for the construction of crossings over large water barriers, electrochemical protection systems, power supply lines, communication systems, etc.), the PPR is developed by a specialized construction and installation (subcontractor) organization and is included in the consolidated PPR.

The consolidated PPR is approved by the general contractor.

2.4. According to the instructions (agreement, contract) of a construction organization, the PPR can be developed by a specialized company selected on a competitive basis and having the appropriate license. In this case, the PPR is approved by the construction organization that ordered the PPR.

2.5. The starting materials for the development of PPR are:

- technical specifications for the development indicating the requirements for the content of the project, the features of the facility under construction, the deadlines for the execution of the project; conditions for construction and installation works in protected zones of other communications;

- a structural diagram of a construction organization with a list and characteristics of all divisions and services included in it, as well as a list and characteristics of subcontractors involved in performing subcontracting work;

- working documentation (project);

- terms of delivery of materials and equipment,

- availability and characteristics of construction machines and vehicles, technological equipment, work quality control devices in a construction organization (taking into account additional purchases and rentals);

- information about the availability of workers in leading construction professions in the construction organization;

- materials for studying the route in situ of existing roads, unloading and storage areas for materials, etc.,

- working conditions (rotation work, expedition method, etc.);

- materials of technical inspection of existing facilities during their reconstruction;

- requirements for the implementation of construction and installation works in the conditions of existing facilities (during reconstruction and expansion).

2.6. The PPR is approved by the technical manager (chief engineer, technical director) of the construction and installation organization, and for specialized subcontracting work it is agreed upon before approval by the general contractor. PPR for expansion, reconstruction or technical re-equipment of existing facilities is agreed upon with the organization operating the facility before approval.

2.7. PPR should be aimed at increasing efficiency and ensuring the required quality of work through the rational organization of preparatory, basic construction and installation, specialized, transport and auxiliary work, the use of advanced technologies, modern machines, technological equipment, quality control instruments, industrial structures, parts and assemblies factory production, the use of complete supplies of materials and products, advanced forms of labor organization.

2.8. The technical solutions adopted in the PPR must ensure energy and material conservation, safe working conditions, minimization of damage to the natural environment, fire and explosion safety.

2.9. Working drawings of temporary buildings and structures (warehouses, sheds, temporary roads, temporary bridges and crossings, etc.), non-standardized technological equipment and devices are included in the PPR.

2.10. The development of individual technological maps, drawings of temporary buildings and structures, inventory and equipment as part of the PPR is not required if there are standard documents for them, information about which is included in the working documentation (project) or in official sources of information.

2.11. The choice of options for general organizational and technological schemes, as well as individual solutions, should be made on the basis of calculations of comparative effectiveness in relation to a specific object.

2.12. The development of PPR is usually carried out using computer technology. Registration of the PPR must comply with the requirements of the design documentation system for construction (SPDS, GOST 21.101-93).

2.13. The approved work project must be transferred directly to the contractors of construction and installation work (CS, SMU, production site) 15-20 days before the start of work.

2.14. During the simultaneous construction of multi-line pipelines (two or more) in a common technical corridor (strip), when a common construction flow is being organized, the following should be developed in the PPR: a general construction master plan, a general transport scheme, a consolidated work schedule (including the sequence of construction of individual pipelines) .

2.15. All organizational and technological decisions must be made in accordance with current laws, building codes and regulations and government standards. To calculate the required amount of material, technical and labor resources, industry or production standards for the consumption of materials, standards and prices for labor assessment, and labor cost standards are used.

2.16. When developing PPR for pipelines laid near existing pipelines and other communications (in their security zone); it is necessary to provide methods for performing work and measures that prevent damage to existing facilities and ensure fire and explosion safety.

When working in a security zone, it is necessary to provide for continuous communication with the organization operating these facilities.

2.17. When reconstructing pipelines, it is necessary to take into account the survey data of the technical condition of the pipeline being reconstructed and its elements, the conditions for dismantling and construction work (gas contamination, the presence of oil and petroleum product spills, crowded conditions, etc.); it is necessary to work out the procedure for interaction between the operating and construction organizations in the event of emergency situations and reflect it in the PPR.

2.18. When carrying out work in winter conditions, it is necessary to take into account the influence of low temperatures, ice conditions, snowfall and snow drifts on the technology and organization of work.

2.19. When constructing facilities in the northern (Polar) climate zone, it is necessary to provide for:

- maximum industrialization of construction;

- use of special equipment;

- measures to combat soil erosion;

- maximum preservation of tundra moss cover;

- weather-appropriate working hours;

- protection of personnel from harsh weather and blood-sucking insects;

- selection of the optimal season for performing certain types of work,

- insurance reserves of production resources.

2.20. When constructing objects in mountainous conditions, it is necessary to additionally provide for:

- technical solutions for preparing construction production;

- safe methods of working on transverse and longitudinal slopes;

- protection of personnel from rockfall;

- organization of drainage;

- application of special organizational and technological schemes;

- specifics of work related to landslides, seismicity, etc.,

- special work regime due to low barometric pressure;

- measures to combat soil erosion and sedimentation.

2.21. When constructing facilities in desert areas and areas with particularly hot climates, it is necessary to provide for:

- special work and rest regime due to high daytime air temperatures;

- use of special equipment for sandy conditions;

- application of measures to preserve the vegetation cover of sandy soils to avoid erosion.

2.22. When constructing facilities in swampy and flooded areas, it is necessary to provide for:

- measures for drainage or water reduction;

- construction of technological passages for the passage of construction equipment;

- application of special technological processes;

- use of special machines and technological equipment.

2.23. When constructing pipelines in difficult natural conditions with new technical solutions (pipes made of new materials, anti-corrosion and heat-insulating coatings, shut-off valves, compensators, pile foundations, etc.), programs for the necessary research, testing and observations are developed as part of the PPR, including the organization of stations and testing grounds , measuring posts and other work ensuring reliable construction work and subsequent operation of structures.

2.24 In seismically hazardous areas, measures are taken to ensure the safety of personnel and the preservation of the property of workers and the enterprise.

3. Composition of the work project

3.1. Project for the production of works for a full range of works.

3.1.3*. Labour Organization.

________________

The section outlines forms of labor organization, work and rest regimes, features of labor organization in specific natural and climatic zones

3.1.1. Construction schedule (linear work schedule) The schedule plan, based on the volume of construction and installation work and construction time, depending on labor costs and required machine time, determines the duration of various types of work, taking into account their technological sequence and compatibility in time.

The contents of the linear work schedule are given in Appendix 2.

3.1.2. Stroygenplan. Traffic diagram

The construction plan and transport diagram indicate household and industrial facilities being built for the construction period (residential towns, production bases), quarries of soft soil, sand, crushed stone and gravel being developed, points for receiving and storing goods, cargo delivery routes (Appendix 3).

The section provides general plans for residential towns and production bases, diagrams of cargo reception and storage points and unloading areas (Appendix 4), scope of work for the construction of temporary buildings and structures, as well as for the construction and provision of transport scheme facilities.

3.1.3. Material support for construction

The section provides technical requirements for the supplied materials and equipment (GOST, OST, TU), a list of documents accompanying the received materials, products and equipment (passport with technical characteristics and a link to the regulatory documents according to which the materials and products are produced, hygienic quality certificate, invoice), the procedure for receiving materials and equipment from the contractor, the procedure for transferring the customer’s equipment to the contractor, the delivery schedule for materials and technological equipment.

The main part of the section is a statement of requirements for basic construction materials, products and technological equipment, as well as a schedule for their delivery for construction (indicating the volumes for each receiving point).

3.1.4. Providing construction equipment

The section provides a list of technical requirements for construction machines, mechanisms, transport and construction equipment, in particular, their actual compliance with the manufacturer’s passports in terms of completeness and equipment, frequency (timing) of scheduled technical inspections and surveys.

The main part of the section is a statement of the need for basic construction machinery, mechanisms, transport and construction equipment, as well as a schedule for their delivery for construction.

3.1.5. Providing construction with labor resources

The section provides links to documents that set out qualification requirements for workers and job descriptions for engineering and technical personnel, provides a list of documents for machine operators (drivers), certificates for persons working with lifting machines, the certification procedure for electric welders and other requirements for construction participants .

The main part of the section is the statement of personnel requirements and the labor movement schedule.

3.1.6. Preparatory work

The work project should highlight: mobilization and preparatory-technological stages of the preparatory construction period.

For each of these stages, the composition and volume of work, the need for material, technical and labor resources, as well as the deadlines for completing the work, used in drawing up the calendar plan and linear construction schedule, are determined.

3.1.7. Basic linear work

The work performed at the main stage of construction of the linear part of the pipeline includes:

- clearing the construction zone from the forest;

- construction of temporary roads, crossings, exits, strengthening of bridges;

- loading and unloading and transport operations, storage of pipes and materials;

- excavation;

- assembly and welding work at the pipe welding base and on the route;

- bending of pipes and sections;

- insulation work,

- laying works;

- ballasting and securing the pipeline;

- thermal insulation device;

- installation of means of associated heating of a pipeline (oil pipeline, oil product pipeline);

- construction of crossings through natural and artificial obstacles;

- intersection of underground utilities, overhead power lines and landlines, work in security zones:

- installation of linear technological units;

- installation of an electrochemical protection system;

- construction of technological communication lines;

- installation of power lines;

- cleaning the cavity and testing the pipeline.

Depending on the construction conditions, this list may be supplemented with other special types of work (drilling and blasting, water reduction, etc.).

This section of the PPR provides:

- technological sequence of work;

- their description;

- a list of regulatory documents, the requirements of which must be observed when performing work;

- links to technological maps and work flow diagrams presented in the annex to the PPR;

- description of types of work not represented by technological maps;

- statements of quantities;

- number, composition and equipment of teams (units) performing linear work:

- technology for performing work indicating the basic requirements.

The timing of the work is reflected in the calendar plan and linear construction schedule.

3.1.8. Solutions for energy supply, water and heat supply

In addition to the text part, working drawings and diagrams are developed.

3.1.9. Work quality control

The GPTR considers the organization and technology of quality control performed by the contractor.

Production control is carried out by accredited laboratories in accordance with the established procedure.

Technical supervision and inspection control are carried out by special services acting in accordance with the powers determined by the provisions on these monitoring organizations.

The draft PPR must contain requirements for quality control of work, including input, operational and acceptance types of control, as well as the procedure for maintaining as-built documentation for all types of work.

The name of the processes subject to control, the subject of control, modes and scope of control, control tools and devices, responsible person, technical criteria for quality assessment and other requirements for the quality and acceptance of work are determined by the corresponding section of technological maps for individual types of work.

3.1.10. Labour Organization

The section outlines forms of labor organization, work and rest regimes, and features of labor organization in specific natural and climatic zones.

3.1.11. Occupational Health and Safety

The PPR contains safety solutions as defined by SNiP III-4-80*, SNiP III-42-80* and other regulatory documents.

3.1.12. Environmental protection

In accordance with the provisions of regulatory documents regulating environmental protection issues, the section provides a list of requirements and measures to prevent and eliminate possible negative impacts on the natural environment both during the construction period (contamination of surface and groundwater with construction waste) and during operation (landscape destruction, soil erosion, disruption of natural flows, hydrological regimes of watercourses and other phenomena).

3.1.14*. Explanatory note

________________

*Numbering corresponds to the original. - Note "CODE".

The explanatory note provides: justification for the choice of work methods, features of work in winter, the need for energy resources, a list of temporary buildings and premises, storage conditions for materials.

General safety requirements are set out as part of the explanatory note of the PPR, and specific measures are reflected in the corresponding section of the technological maps for certain types of work.

3.2. Production project for special types of work

A production project for performing special types of work or a linear part (drilling and blasting operations, a compressor station connection unit combined with launch and receiving chambers for cleaning devices, etc.) is developed in a more abbreviated form and includes:

- Work schedule;

- construction master plan (local);

- technological maps.

3.3. Work project for the preparatory construction period

If, by decision of the construction organization, a separate project for the execution of work for the preparatory period of construction is developed, then it must contain:

- calendar plan for preparatory work;

- general decisions on the organization of work;

- schedule for preparatory work;

- construction plan of the pipeline route with the diameters of the construction strip, indicating the boundaries of the forest, intersections with watercourses and roads, where necessary, crossings and exits, temporary roads and other objects constructed during the preparatory period;

- a diagram of temporary roads indicating the scope of work for their construction, indicating quarries of local materials; points for receiving goods and storing them, distances for transporting goods;

- technological maps for certain types of work included in the preparatory period (clearing the route from forest, removing the fertile layer of soil, constructing flat roads and along the route, constructing helipads, constructing crossings over watercourses, etc.);

- schedule of movement of equipment:

- schedule of movement of workers;

- schedule of receipt of construction materials;

- quality control of work;

- safety precautions;

- environmental protection.

4. Contents of the work schedule

4.1. The work schedule is presented in tabular form and in the form of a graph.

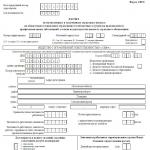

The volumes by type of work and resource costs are given in tabular form. The table form is shown below.

|

Name |

Scope of work |

Labor costs |

Required machines |

Pro- |

Number of shifts |

Number |

Number |

|||

|

Unit |

Quantity |

Nai- |

Chislomash.- |

living |

work- |

ma- |

||||

4.2. Calculation of the number of person-days and mash.-see is carried out according to the indicators specified in the technological maps.

4.3. A separate table shows the composition of the teams and their equipment with machines, equipment and devices. The table form is shown below.

|

Name of brigades (units) |

Composition of brigades (units) |

Resource availability |

||

|

profession, rank, quantity |

Name of machines, equipment and devices |

Quantity |

||

4.4. The number of workers and the amount of resources are given taking into account the insurance reserve.

4.5. The work schedule is given in the form of a cyclogram or linear graph.

A linear graph is recommended for linearly extended objects (linear part of a pipeline, communication line, power line).

On the line graph it is necessary to show: the situational plan of the route; the boundaries of the work of teams (links) and the direction of their movement, the dynamics of movement in time and space, taking into account changes in the intensity of production depending on the complexity of the route section.

The work schedule must meet the requirements of the technological sequence of work and their maximum combination in time, synchronization of types of work and optimization of technological advances.

4.6. The basis for developing a work schedule is the construction schedule contained in the “Construction Organization” section of the project documentation or an agreement concluded between the customer and the contractor.

, it usually takes no more than a few minutes. [email protected], we'll figure it out.

Each properly organized construction must have well-written construction documentation, which, as a rule, includes the development of documents such as a traffic management project (abbreviated as POD), construction organization project (abbreviated as POS) and work production project (abbreviated as PPR). All these documents are capable of ensuring the safety of employees during construction and installation work, ensuring the correct organization of the actual construction of the facility itself, as well as improving the quality of construction work performed.

Today, due to the fact that construction work has become characterized by the highest degree of severity, there is a need for the creation and more responsible development of technological and technical solutions that are used in the production of work. That is why the main and most significant document in the system of organizational and technological training becomes the PPR document in construction - download for free, which can be found at the end of this article.

This document contains a list of technological rules, requirements for labor protection and safety and environmental safety, among other things. Based on the work project, construction work is organized, the necessary materials and resources are determined, the deadlines for completing the work are determined, and possible risks are worked out.

Who develops the PPR?

Work projects for the construction of new structures or for the reconstruction or expansion of any facility are developed by general contracting construction and installation enterprises. If PPRs are ordered by a general contracting or subcontracting construction and installation organization, then they can be developed by design and technology institutes or design and engineering organizations.

It should also be noted that sometimes, when carrying out large volumes of work, PPRs are drawn up not for the object as a whole, but for a specific type of work, for example, for the installation of prefabricated structures, for excavation work, for roofing work, etc. Previously, such documents were called work organization projects (abbreviated POR), but in the current standards SNiP 12-01-2004 instead of SNiP 3.01.01-85, they are also called WPR with the proviso that these are projects for the production of specific works. When carrying out certain types of work related to general construction, special or installation work, PPRs are developed by companies that are directly involved in this.

Composition of PPR

- Work schedule;

- Technological maps;

- Construction master plan;

- Schedules for receipt of construction materials, products and equipment at the site;

- Lists of technological equipment and installation equipment;

- Worker movement schedules around the facility;

- Solutions for geodetic work;

- Safety solutions;

- Explanatory note, which should contain:

- justification of decisions on the implementation of certain types of work, including those performed in winter;

- calculations of temporary utility networks;

- measures that would ensure the safety of materials, products and structures, as well as equipment at the construction site;

- a list of mobile structures with calculation of the need and justification of the conditions for their location on the construction site;

- measures to protect these structures from damage, as well as environmental protection measures.

But it is worth noting that only 4 documents remain the main ones in the PPR: construction plan, work schedule, explanatory note and technical map. Let's look at them in more detail.

The key PPR document in construction is, of course, the work schedule. The success of the entire project largely depends on the literacy of its development. In short, the calendar plan is a model of construction production, in which the sequence and timing of construction work at the site are clearly and accurately established.

The second most important PPR document remains the construction master plan (or abbreviated construction plan). The quality of its preparation primarily determines the reduction of costs for organizing a construction site, which at the same time allows for the creation of safe working conditions for workers. When developing a construction plan, specialists take into account various methods of organizing a construction site, from which the most rational one is subsequently selected.

The next no less important PPR document is the technological map, which determines the most optimal methods and sequence of performing a particular type of work. In addition, labor costs are calculated here, the necessary resources are determined and the organization of labor is described. Technological maps, as a rule, include graphic and text documents, which may include workplace diagrams, which indicate the scope of work and the boundaries of the areas into which the object is divided. In principle, technological maps can be of three types:

- typical without reference to specific objects;

- typical with reference to standard objects;

- individual with reference to a specific project

And the last important element of the PPR can be called an explanatory note, in which, as mentioned above, all kinds of labor protection measures are indicated, the conditions and complexity of construction are determined, the presence of warehouses and temporary structures is justified, etc. In addition, the explanatory note provides technical and economic indicators of construction.

You can download the PPR for construction.

PIC and PPR in construction - this O the most basic documents, without which activities at a particular facility cannot be started.

The construction organization project and the work execution project are one of the most important documents that are necessary to begin construction work at the site.

What is POS

This document is developed immediately for the entire construction and provides for all stages of production and their clearly established deadlines.

This document describes the calendar plan of actions, all automated resources that are necessary for installation work, financial costs, technical support and distribution of labor, depending on the number of specialists, the scope of the project and the construction period.

To develop a construction organization project, you will need information about the facility, on the basis of which documentation is drawn up. Development of POS in construction This is done by companies that provide construction services, including ours.

As a rule, a construction organization plan includes the following sections:

- calendar plan for construction and installation work;

- construction conditions;

- explanatory note;

- general plan;

- documentation of communication support.

Depending on the nature of the object, the document may contain other clauses providing for the organization of installation and construction activities on the site.

What is PPR

The work plan is also one of the necessary documents for installation, repair or construction work. The PPR fully specifies the action plan and all the necessary requirements for organizing construction. Safety rules, labor protection, and other aspects of employee safety must be prescribed here.

The work plan is also one of the necessary documents for installation, repair or construction work. The PPR fully specifies the action plan and all the necessary requirements for organizing construction. Safety rules, labor protection, and other aspects of employee safety must be prescribed here.

PPR is developed specifically to optimize the production process. That is, it prescribes the most effective technology for the construction of a particular facility, thanks to which the work is completed in the shortest possible time with maximum efficiency.

The PPR fulfills the following goals:

- regulates the orderliness of work equipment and the improvement of the work space, taking into account safety rules;

- dictates the organization of the work process and the choice of work methods and technologies in order to speed up construction without loss of quality;

- requirements for environmental safety and labor protection;

- prescribes possible risks associated with work issues and provides for an extension of construction time in connection with them.

A work project can be ordered from an organization that specializes in the preparation of such construction documentation. A PPR can also be developed by a company that performs repair, construction and installation work. This project must be prepared by a qualified engineer, since the entire construction project, financial costs, efficiency and employee safety depend on the PPR.

A work project can be ordered from an organization that specializes in the preparation of such construction documentation. A PPR can also be developed by a company that performs repair, construction and installation work. This project must be prepared by a qualified engineer, since the entire construction project, financial costs, efficiency and employee safety depend on the PPR.

The work plan, before entering into force, is approved by the general contractor's engineer. If everything is normal in the documentation and the document is approved, then it is transferred to the construction site for review by all management officials.

Sometimes additional approvals of the work plan may be necessary, depending on the type of facility and location of construction or installation:

- if installation or construction work takes place outside the construction site, then coordination with the owner of this territory is necessary;

- if production affects the roadway, approval is required from the traffic police;

- in case of contact with communications during construction or installation work, prior approval of the relevant authorities is required.

That is, if, in addition to the allocated object, objects of other properties fall under the construction process, the PPR must be agreed upon with their management or owners.

The PPR includes the following aspects:

In addition, the PPR may also include special clauses that provide for certain factors, depending on the nature of the construction work.

What is the difference

A construction organization project and a work execution project are completely different documents. Both must be present at the start of construction.

The work project is developed on the basis of the construction organization project. That is, first you need to register the PIC, and then the PPR. Consequently, the first step is to develop all the factors influencing the organization of construction, and then all the nuances of production work are prescribed.

The work project is developed on the basis of the construction organization project. That is, first you need to register the PIC, and then the PPR. Consequently, the first step is to develop all the factors influencing the organization of construction, and then all the nuances of production work are prescribed.

In connection with what is described above, the PPR cannot contradict the norms prescribed in the PIC. that is, PIC documents are primary and more important than PPR. This is due to the fact that the construction organization project is necessary for the entire construction project as a whole, and the PPR provides for organizational issues at a specific site, which is located at the construction site to which the PIC is prescribed.

To create a PPR, you need to provide a PIC, and in addition to it, additional data. First, you need a clearly formulated technical specification, which is based on the wishes of the customer. Then you need to collect all the documents for demolition and dismantling, if this type of work is envisaged at the site.

In conclusion, I would like to note that PIC and PPR in construction are an integral part of the necessary documentation, without which it is impossible to start activities at the site. These two documents carry completely different loads, although they are closely related. The construction organization project is more important and characterizes all types of activities as a whole at the site, and the work execution project describes the requirements for a certain small area that relates to this object. The development company or a specialized organization can develop the necessary documentation.